Dual clutch transmission

A dual-clutch transmission, clutch technology, applied in the direction of vehicle gearboxes, gear transmissions, transmission components, etc., can solve the problem of increasing gear fatigue, and achieve the effect of reducing possibility, reducing wear, and optimizing load distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

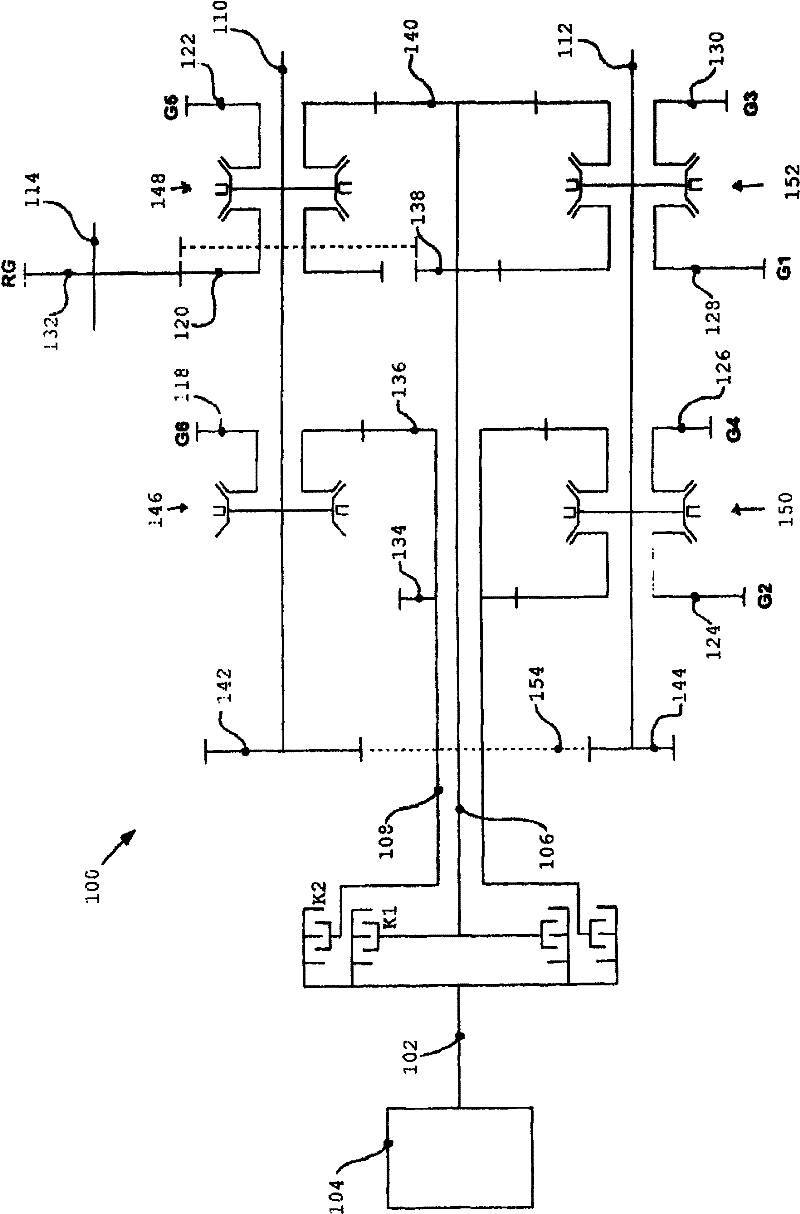

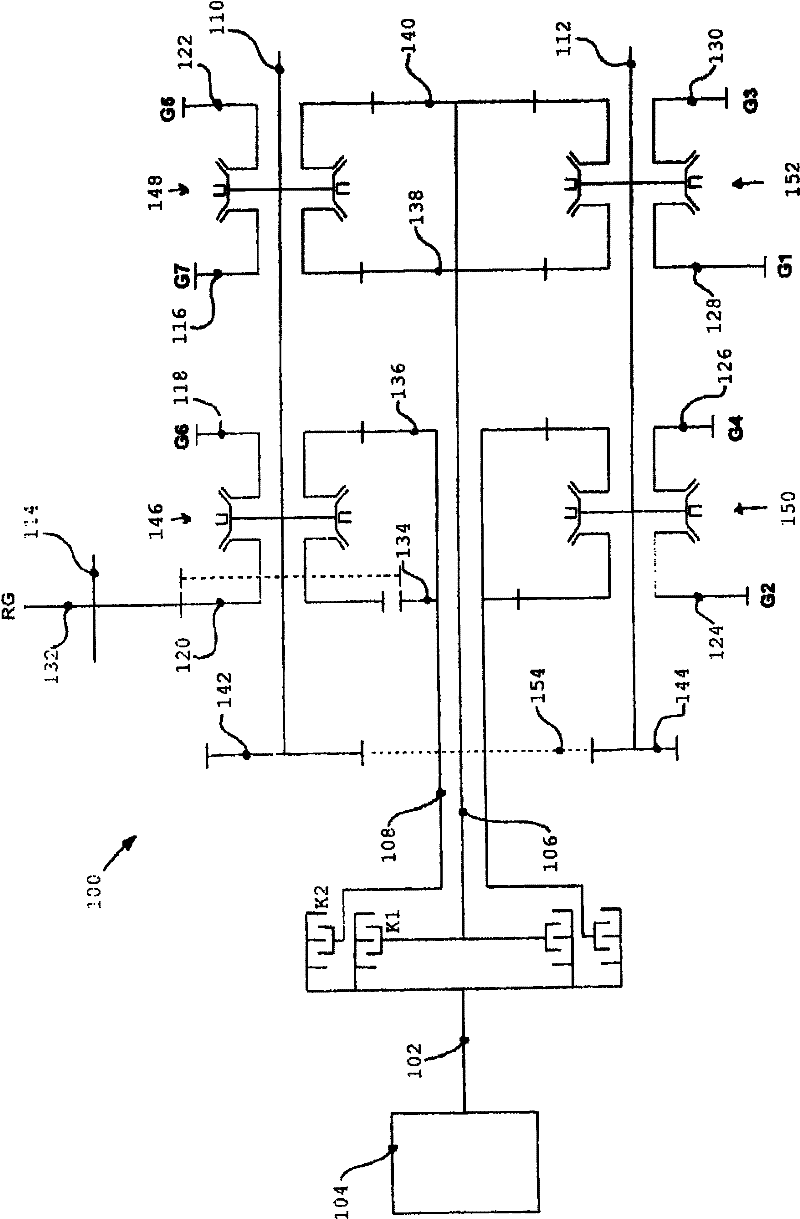

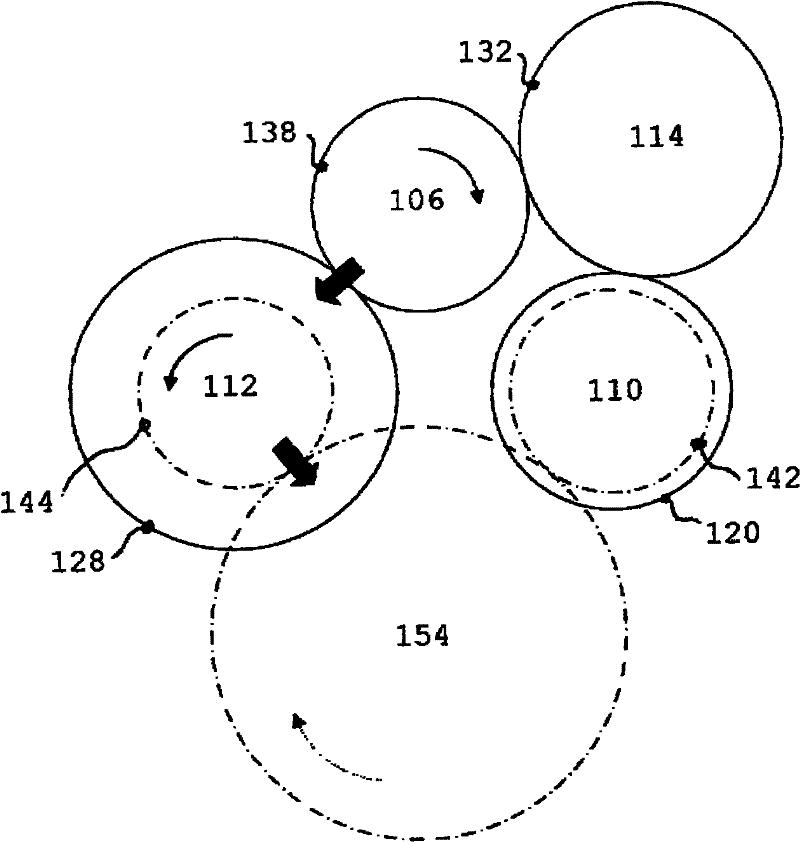

[0017] figure 1 3 shows a representative schematic diagram of the dual clutch transmission 100 of the present invention, with reference to figure 1 Turning to FIG. 3 , an embodiment of the present invention and its technical advantages can be better understood.

[0018] The first clutch K1 and the second clutch K2 are mechanically connected via a drive shaft 102 to a prime mover 104 in a conventional manner. Each clutch is also mechanically connected with the first input shaft 106 and the second input shaft 108 . The second input shaft is concentric with the first input shaft. Therefore, depending on the selected clutch, the driving force of the engine is applied to one of the input shafts. Fixed drive gears 134, 136 are connected to the first input shaft and fixed drive gears 138, 140 are connected to the second input shaft. The first output shaft 110 and the second output shaft 112 are arranged in parallel with respect to the input shaft. Driven idler gears 118, 120, 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com