Dynamic sealing device for single shaft of casting mold numerical control machine

A numerical control machine tool and dynamic sealing technology, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of not meeting the requirements of use, not being able to achieve dust-proof sealing effect, etc., achieving long service life, convenient installation, preventing The effect of the invasion of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

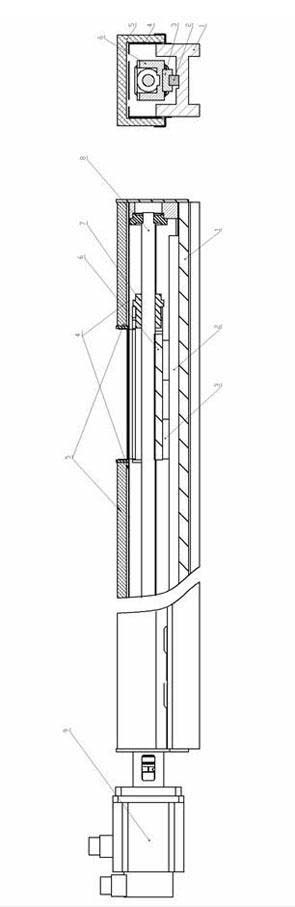

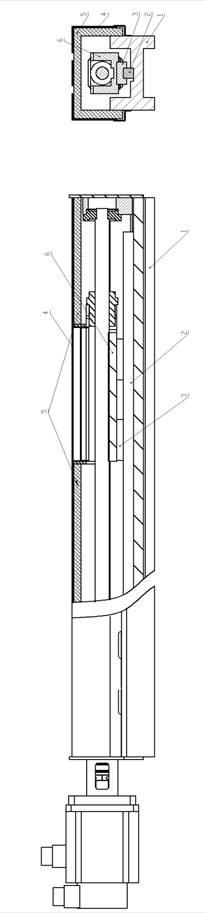

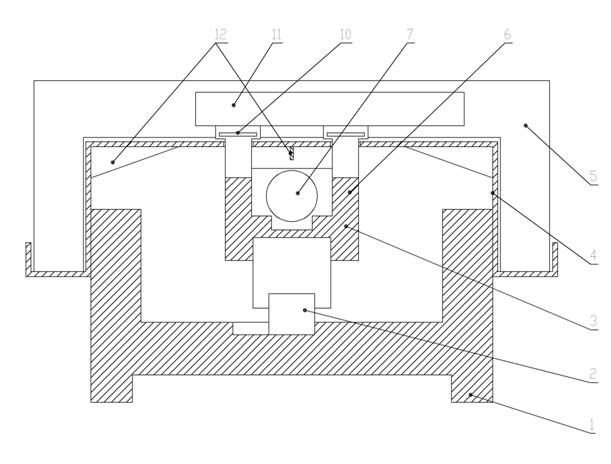

[0024] The single-axis dynamic sealing device used for casting CNC machine tools is characterized in that the device is composed of a base 1, a guide rail 2, a dust-proof structure, and a sliding mechanism. The dust-proof structure is composed of a metal cover 4 and an organ cover 5, the base 1 is fixed, the guide rail 2 is fixed on the base 1, the slider 3 and the guide rail 2 form a sliding pair, and the connecting block 6 is connected with the guide rail. Realize the reciprocating movement of the connecting block 6 along the direction of the guide rail 2, one side of the organ cover is connected with the base 1, and one side is connected with the connecting block 6, and the organ cover can freely shrink as the connecting block moves back and forth, so Said metal cover 4 is fixed with the base 1, and the periphery is all sealed with the base. Describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com