Cylindrical gasholder sealing device

A technology of a sealing device and a gas tank, applied in the sealing field, can solve the problems of increased wear of sealing rubber strips, sealing failure, insufficient sealing oil level of a piston oil groove, etc., and achieve the effect of improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

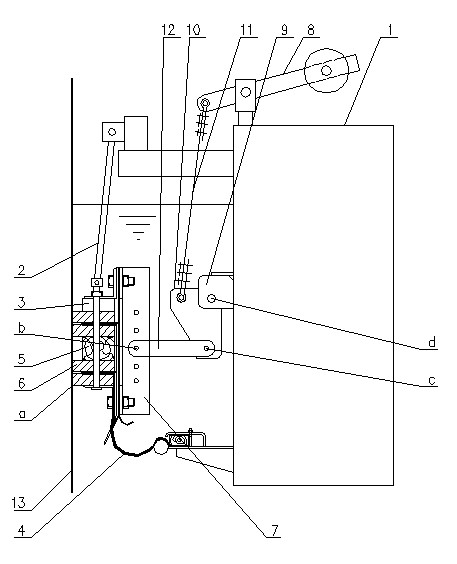

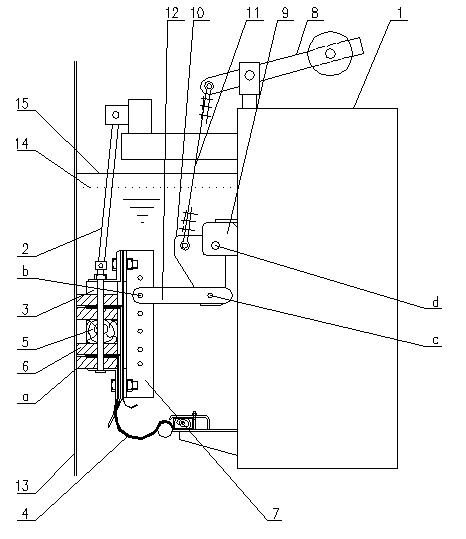

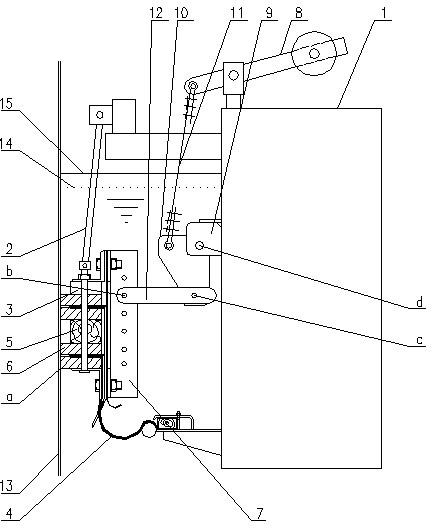

[0014] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0015] figure 2 It is a structural schematic diagram of the present invention, as shown in the figure, the cylindrical gas holder sealing device of the present invention includes two groups of sealing assemblies arranged up and down along the axis of the gas holder, and a rubber suspension mechanism fixed on the piston box beam 1 2 and a rubber pressing mechanism; the sealing assembly includes a pressing plate 3, a sealing canvas 4, a sealing rubber strip 6 separated by a clamping wood 5, and a rubber clamping mechanism 7, which are connected as a whole by a screw, and the sealing canvas 4 One end is installed between the sealing rubber strips 6, and the other end is installed on the piston box beam 1; the sealing assembly is suspended on the piston box beam 1 through the rubber suspension mechanism 2; The counterweight lever 8 connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com