On-line inspection equipment for automobile engine cylinder block

A technology of automobile engine and engine block, which is applied in the detection field, can solve the problems such as few parameters of engine block detection, no cylinder hole measurement, no automatic measuring machine, etc., and achieve more measurement parameters, more sampling points, and higher precision high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings, but not as a limitation of the present invention.

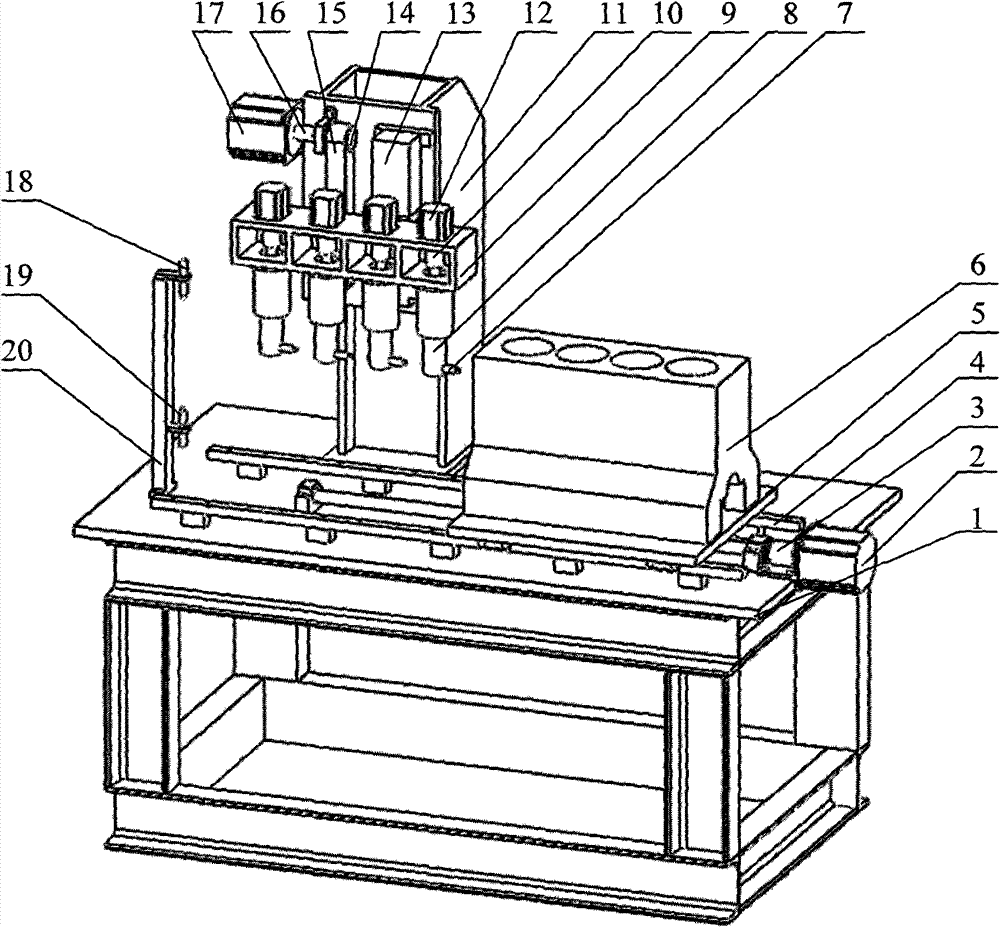

[0019] The equipment includes a base platform (1), the motor (2) fixed above the base platform is connected with the screw guide rail (4) through the coupling (3), and the engine block detection workbench (5) is fixed above the guide rail. , the engine block (6) is placed on the detection workbench. The cylindricity measurement base (11) is fixed on the base platform, the high-precision air-floating guide rail (13) is fixed on the cylindricity measurement base, the cylindricity measurement adapter plate (9) is connected with the air-flotation guide rail sleeve, and the motor ( 12), high-precision air bearings (8) and displacement sensors (7) form four groups of cylindricity measuring mechanisms installed on the adapter plate, and the cylindricity measurement motor drives the rotation of the air bearing to drive the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com