Dynamic detection testing machine of bumper

A dynamic detection and buffer technology, applied in railway vehicle testing, etc., can solve problems such as unreliability, hidden dangers, unsafe use of equipment, etc., and achieve the goal of reducing materials, reducing equipment costs, and avoiding national property and casualties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

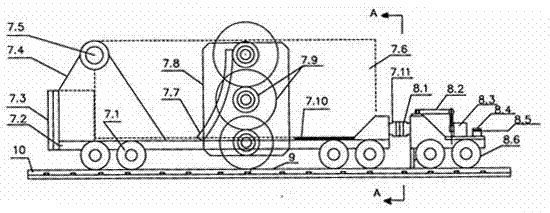

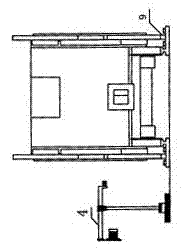

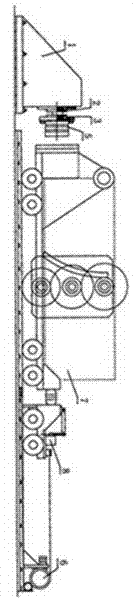

[0022] Such as Figure 1~3 As shown, the main structure of the present invention includes a load-bearing track 10, a test piece installation base 1 with a test piece installation base 3 and a load sensor 2, a buffer test piece 5 is fixed on the test piece installation base 3, and the load sensor 2 Set between the test piece installation base 3 and the test piece installation base 1, a distance measuring sensor and a speed sensor group 4 are arranged at the horizontal position along the outer end surface of the buffer test piece 5; The load test vehicle 7 and the traction control vehicle 8 of the uncoupling head are provided with a traction power group 6 at the end of the load-bearing track on one side of the traction control vehicle 8, and the traction power group connects the traction pile 8.4 on the traction control vehicle through the traction steel rope 8.5 connection, the traction control vehicle is also provided with a decoupling action handle 8.2 and a decoupling contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com