Probe-based automatic airflow pressure and velocity measurement device

An automatic measurement and probe technology, which is applied in the direction of measuring fluid pressure, measuring devices, and measuring fluid pressure through electromagnetic components, can solve the problems of difficulty in knowing the direction of local airflow in advance and low efficiency, so as to reduce errors and increase experimental speed , The effect of simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

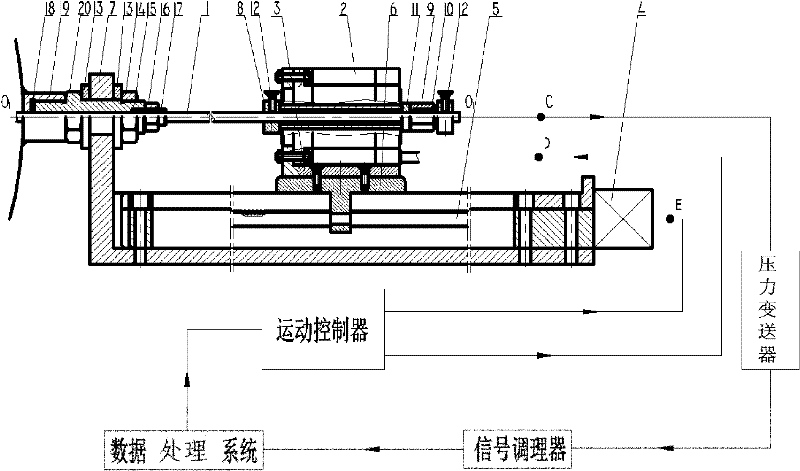

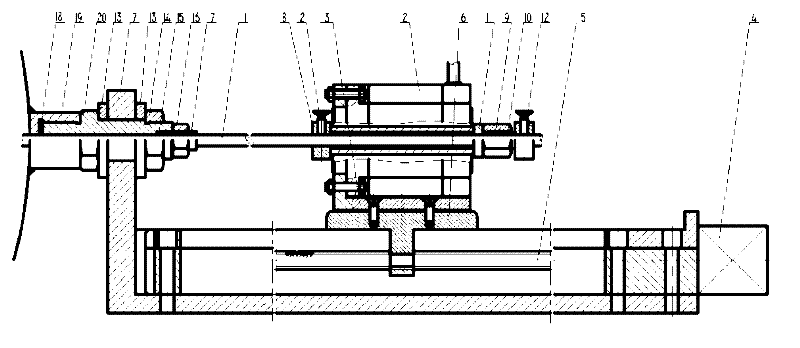

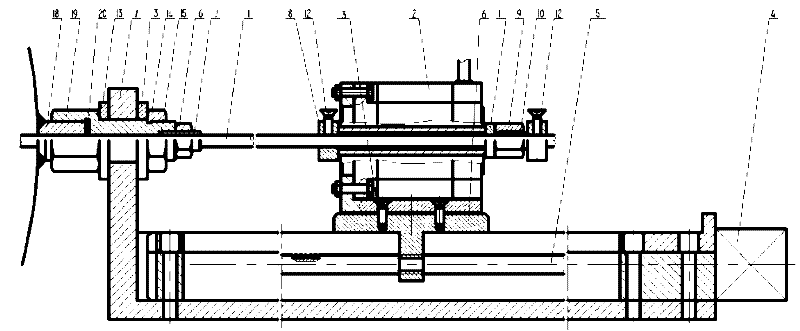

[0015] Such as figure 1 As shown, a measuring device for air pressure and velocity that controls the automatic movement of the probe includes four parts: the probe rotary motion adjustment mechanism, the probe linear motion adjustment mechanism, the installation support structure, and the data acquisition and control system.

[0016] The probe rotation movement adjustment mechanism includes a hollow motor 2, a hollow motor bracket 3 and a probe positioning and locking device, wherein the positioning and locking device consists of a positioning sleeve 8, a positioning lock nut 9, a screw 10, a gasket 11 and a jacking screw 12 composition. The positioning sleeve 8 is placed on the left side of the hollow shaft of the hollow motor 2 and is firmly connected with the inner wall of the hollow shaft and the probe 1 through interference fit, and the top screw 12 locks the connection between the positioning sleeve 8 and the probe 1 . The positioning lock nut 9, the gasket 11 and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com