Wafer-grade packaging method of ultraviolet LED packaging structure

A technology of LED packaging and manufacturing methods, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of device performance degradation, device reliability degradation, and easy intrusion into the chip surface, so as to avoid damage, realize airtight reliability, Effect of improving device production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

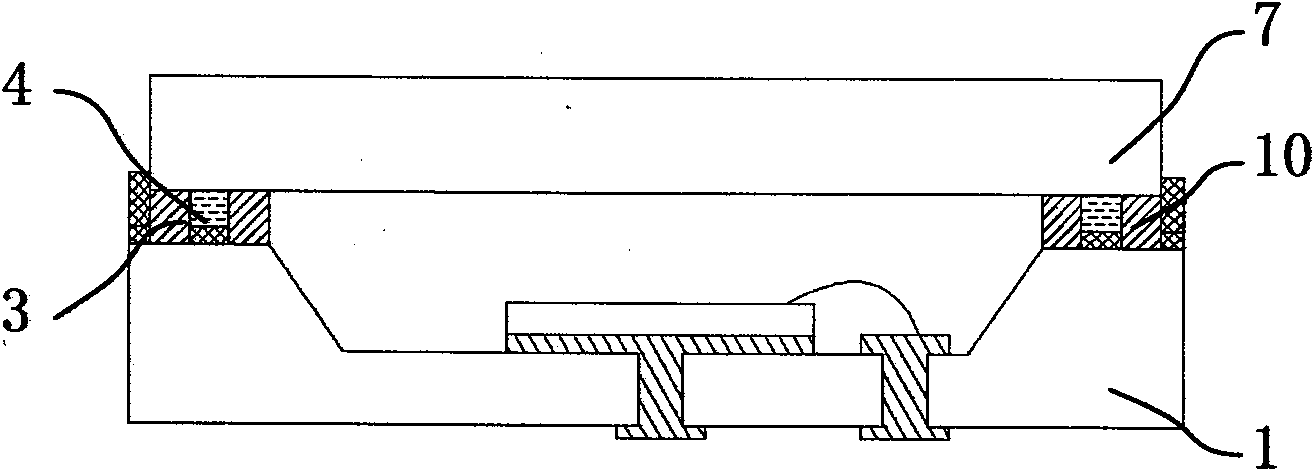

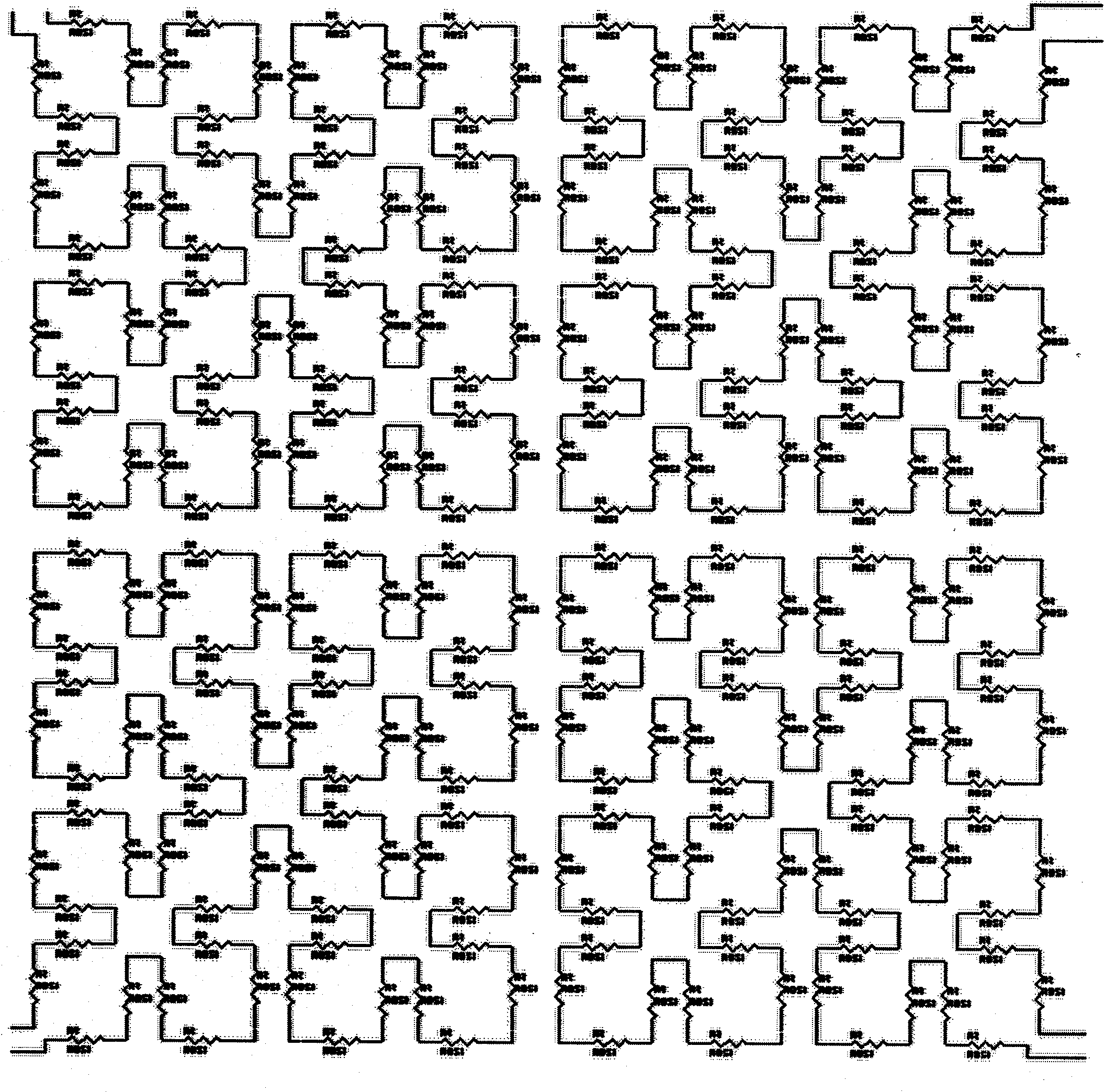

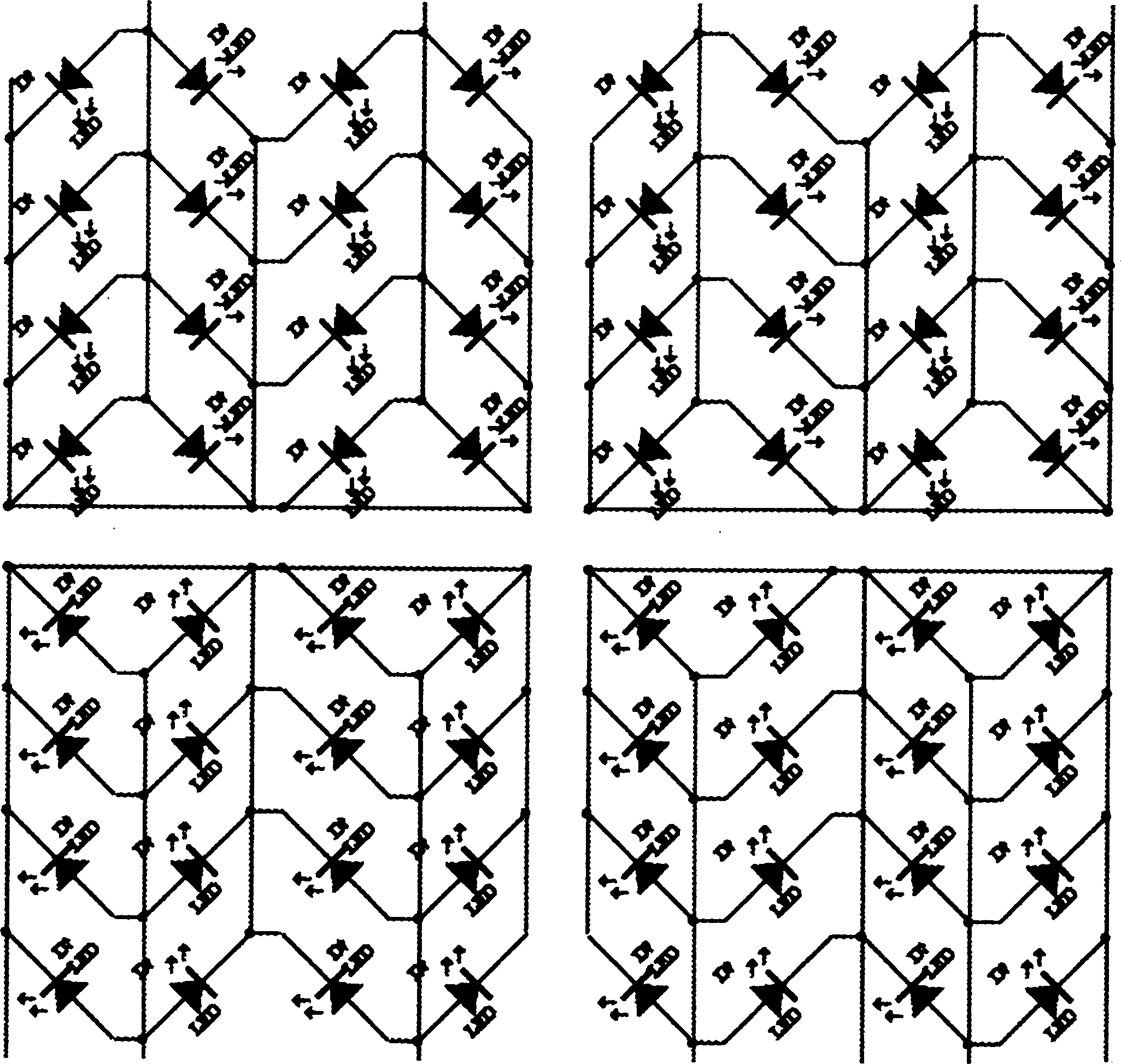

[0040] like figure 1As shown, it is a single-layer concave cup wafer-level ultraviolet LED packaging structure in this embodiment, including a packaging substrate 1, an LED chip 6 placed on the upper surface of the packaging substrate 1, and a packaging lens 7 packaged on the LED chip 6. The packaging The upper surface of the substrate 1 is provided with a concave cup 8 for accommodating the LED chip 6, and two conductive through-holes 9 are arranged at the bottom of the concave cup 8, and the conductive through-holes 9 are filled with two through holes connected to the electrodes of the LED chip 6. The hole electrode 5 is also provided with a bonding structure 10 for bonding the package lens on the wall of the concave cup 8. The bonding structure 10 includes a local heating circuit 4 and an airtight bonding substance 3 wrapped outside it. In addition, in The position corresponding to the local heating circuit 4 and the packaging substrate 1 is also provided with an insulating...

Embodiment 2

[0046] This embodiment is similar to Embodiment 1, the difference is that the LED chip 6 is a horizontal structure, which is fixed at the non-electrode position at the bottom of the concave cup 8, and the electrodes of the two chips 6 on the LED chip 6 are respectively connected by gold wires. on the two via electrodes 5 .

Embodiment 3

[0048] This embodiment is similar to Embodiment 2, except that the two chip electrodes of the LED chip are up and down, the LED chip is fixedly connected to one through-hole electrode, and the other chip electrode is connected to the other through-hole electrode through a gold wire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com