Control apparatus for electric rotating machine

一种控制设备、旋转电机的技术,应用在电动发电机控制、交流电动机控制、电子换向电动机控制等方向,能够解决不准确等问题,达到减少改变次数的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

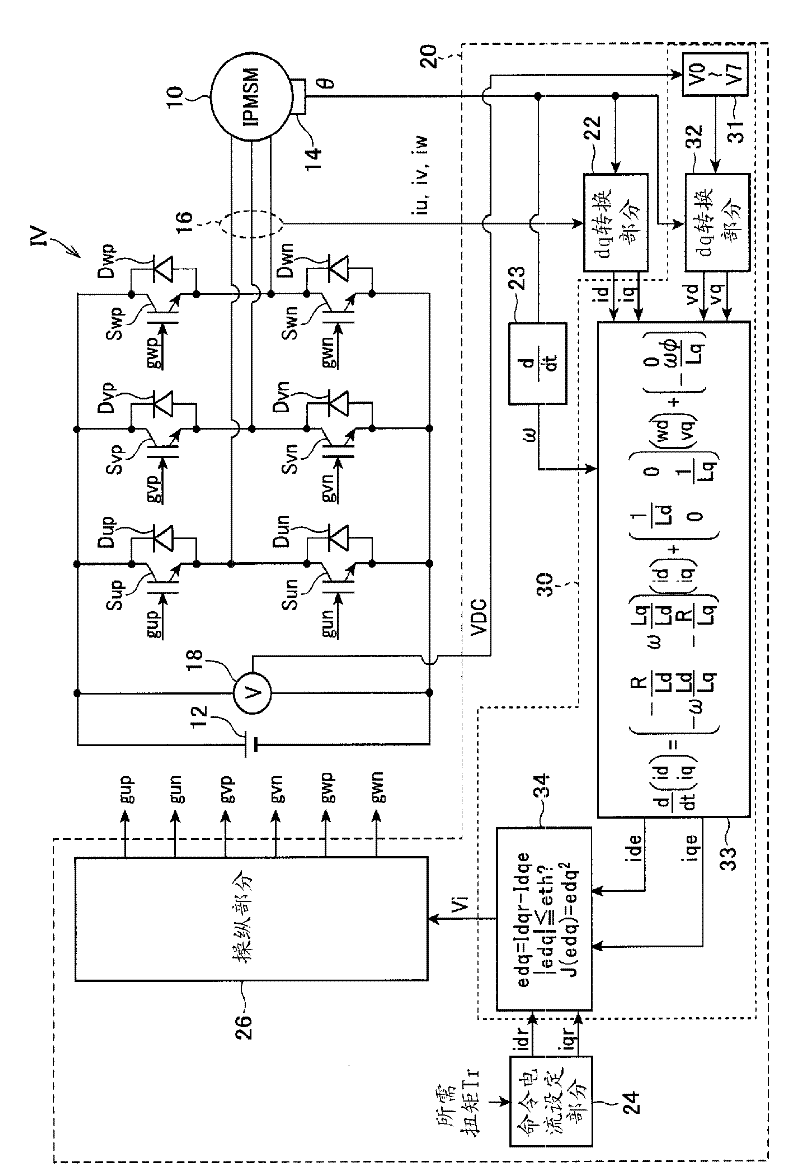

[0030] figure 1 is a diagram showing the overall structure of a control system for controlling a motor / generator 10 mounted on a hybrid vehicle, the control system including the control device 20 according to the first embodiment of the present invention. Motor / generator 10 is a three-phase permanent magnet synchronous motor. The motor / generator 10 is also a rotating electrical machine with salient poles. That is, the motor / generator 10 is an IPSM (Interior Permanent Magnet Synchronous Motor).

[0031] The motor / generator 10 is connected to a high voltage battery 12 through an inverter IV. The inverter IV includes a series connection of switching elements Sup and Sun, a series connection of switching elements Svp and Svn, and a series connection of switching elements Swp and Swn. These series-connected connection nodes are respectively connected to the U-phase, V-phase and W-phase windings of the motor / generator 10 . As each of the switching elements Sup, Sun, Svp, Svn, Sw...

no. 2 example

[0093] Next, a second embodiment of the present invention will be described, wherein the differences from the first embodiment will be particularly emphasized.

[0094] Figure 13 is a flowchart showing the operation of the model predictive control performed in the second embodiment. The operations are repeatedly performed by the control device 20 at regular time intervals. exist Figure 13 in, with Image 6 The same step numbers shown in represent the same steps.

[0095] The operation differs from the equivalent operation of the first embodiment in the condition for setting the state transition permission flag F to 1. The condition in the first embodiment is that the magnitude relationship between the norm |Idqr| of the command current vector Idqr and the norm |Idqe| of the predicted current vector Idqe is reversed. But in the second embodiment, the condition is that the end point of the error vector edq whose starting point is at the origin reaches a straight line ( ...

no. 3 example

[0098] Next, a third embodiment of the present invention will be described, in which differences from the first embodiment will be particularly emphasized.

[0099] Figure 15 is a flowchart showing the operation of the model predictive control performed in the third embodiment. The operations are repeatedly performed by the control device 20 at regular time intervals. exist Figure 15 in, with Image 6 The same step numbers shown in represent the same steps.

[0100] The operation differs from the equivalent operation of the first embodiment in the manner in which the average voltage vector Va is calculated. In a second embodiment, the average voltage vector Va is calculated in step S16a by calculating a simple moving average of the voltage vectors V(n), V(n-1), ... V(n-N), where the voltage vector V (n), V(n−1), . . . V(n−N) represent operation states respectively adopted at past N (>2) update timings up to the previous update timing. Since the period of the control cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com