High-precision direct-reading gas meter

A direct-reading, high-precision technology, used in signal transmission systems, instruments, volume indicators and recording equipment, etc., can solve problems such as counting errors and inaccurate gas meter counting, reduce costs, and eliminate wiring construction and maintenance investment. , the effect of improving the counting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

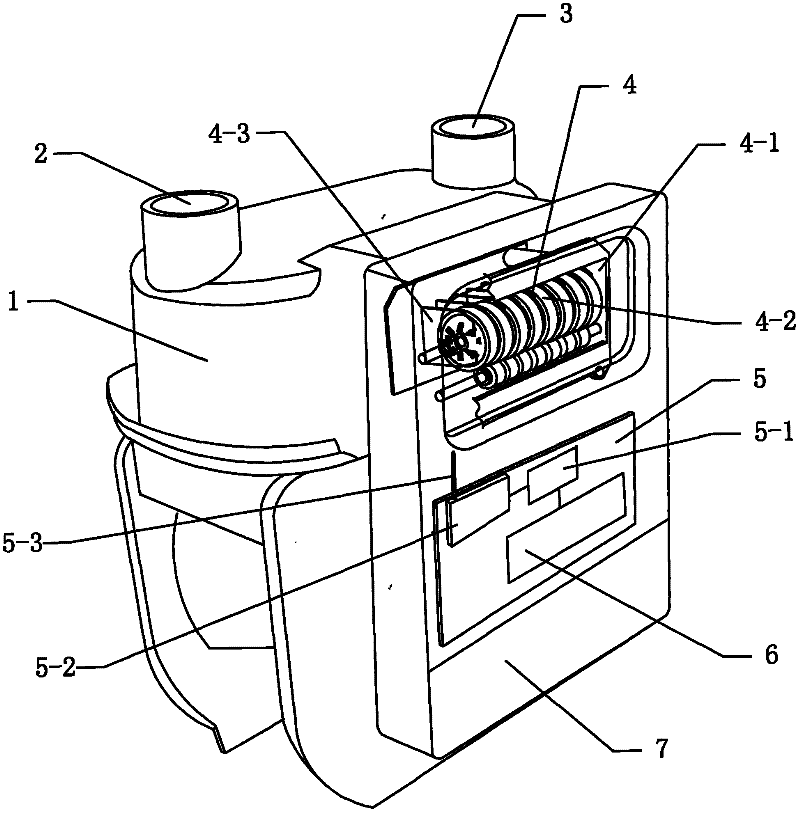

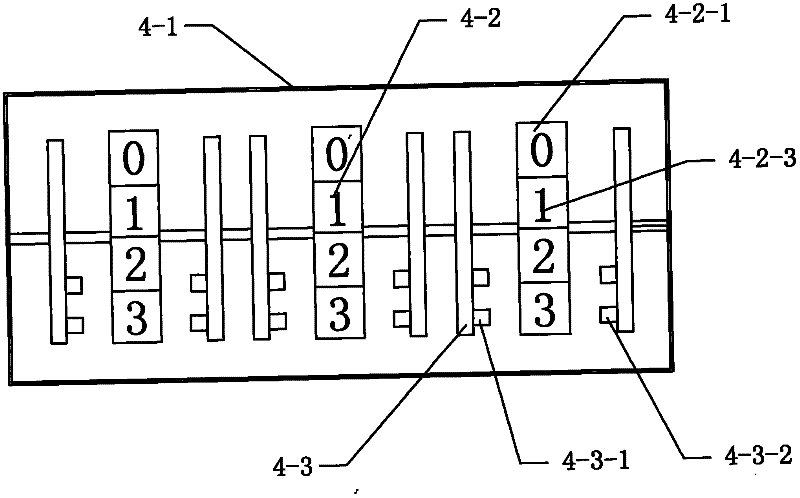

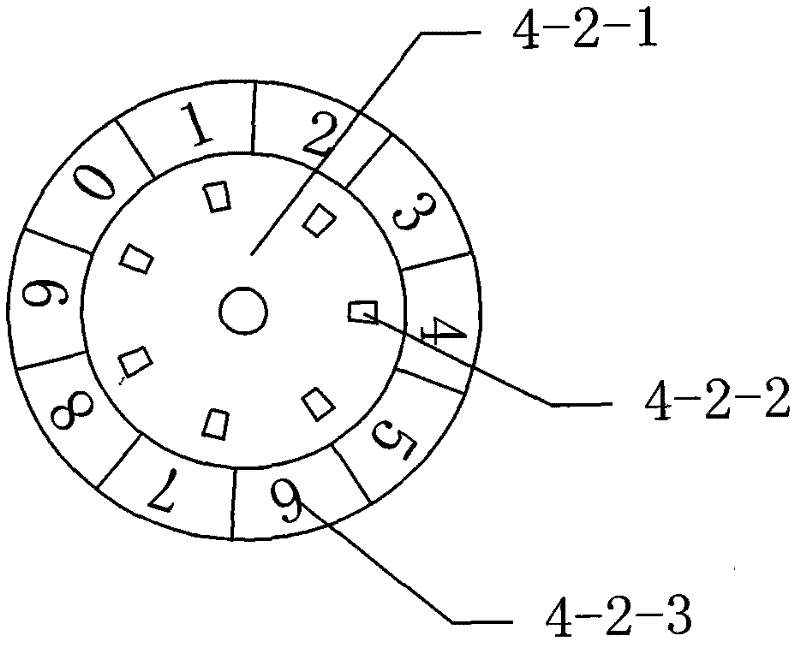

[0024] A high-precision direct-reading gas meter of the present invention such as figure 1 As shown, it is mainly composed of a housing 1, an air inlet 3 and an air outlet 2 provided on the housing 1, a battery box 7 installed in the housing 1, a counter 4, a master control circuit board 5 and an LCD display 6. A battery is housed in the battery box 7, which supplies power for the circuit part of the whole gas meter. The master control circuit board 5 carries out electrical control to the whole gas meter, and a processor 5-1 is mainly welded thereon. The air inlet hole 3 and the air outlet hole 2 communicate with the counter 4, and the counter 4 is pushed to count. The mechanical count value obtained by the counter 4 is returned to the processor 5-1 for digital processing to obtain a digital count value. The LCD display screen 6 is connected to the processor 5-1 to display the electronic count value processed by the processor 5-1.

[0025] The design core of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com