Air gap type BBO (Barium Boron Oxide) laser polarizing prism

A technology of polarizing prism and air gap, applied in the field of polarizing prism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

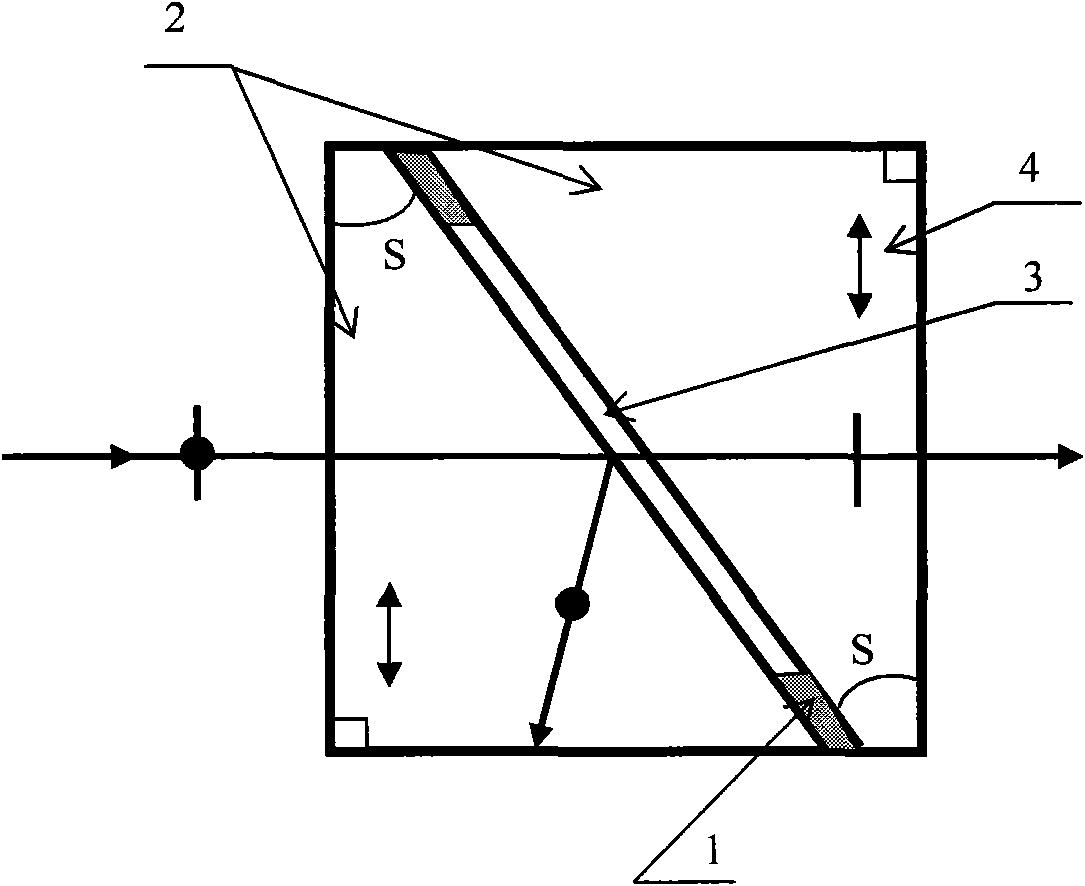

[0010] As shown in the figure, the device of the present invention is composed of a rectangular prism 2 and an organic film spacer 1 . Select optical high-quality BBO single crystal, determine the crystal optical axis direction 4, make a long blank with a square or regular polygonal light end surface, cut the blank along the side, and divide it into two right-angle prisms, two right-angle prisms The size can be different, but the wedge angle S of the two right-angle prisms should be consistent during the grinding and polishing process; the right-angle prisms should be treated with moisture-proof after polishing, and a moisture-proof film with a thickness of about 150nm should be vacuum-plated on the polished surface. An elliptical hole is opened in the center of the organic thin film spacer layer 1, the ratio of the long and short axes of the ellipse is 1.3, and the distance between the ellipse and the periphery of the thin film spacer layer is 1mm. As shown in the figure, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com