Glass substrate bonding method, glass assembly, package manufacturing method, package, piezoelectric vibrator, oscillator, electronic device, and radio-controlled timepiece

A piezoelectric vibrator and glass substrate technology, applied in the field of radio clocks, can solve the problems of increased sheet resistance of Si film, applied voltage of Si film, increased energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0055] (Piezo Vibrator)

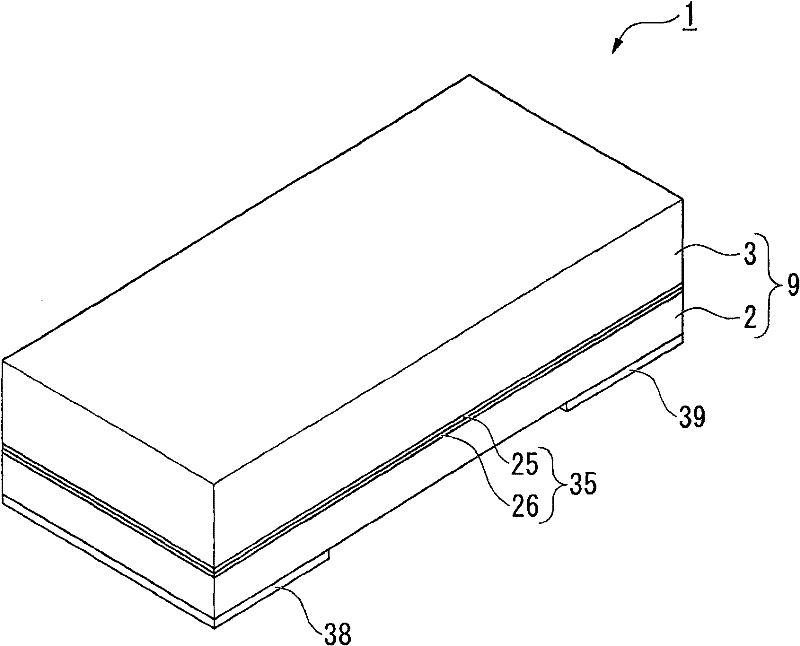

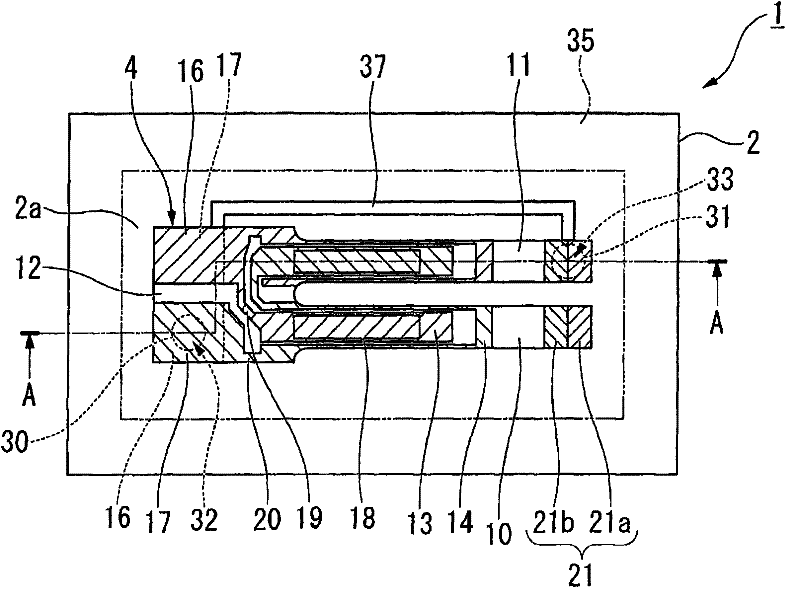

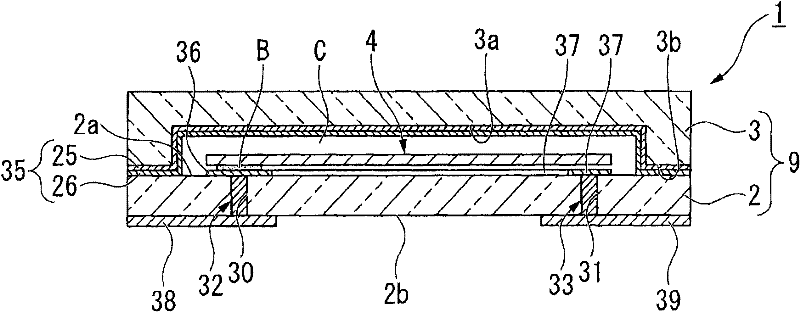

[0056] Hereinafter, a piezoelectric vibrator according to an embodiment of the present invention will be described with reference to the drawings. figure 1 It is an external perspective view of the piezoelectric vibrator according to the embodiment. figure 2 It is a plan view of the piezoelectric vibrator in a state where the cover substrate is removed. image 3 is along figure 2 A side sectional view of line A-A. Figure 4 It is an exploded perspective view of a piezoelectric vibrator. Also in Figure 4 In the drawing, the illustration of the excitation electrode 15, the lead-out electrodes 19, 20, the assembly electrodes 16, 17, and the weight metal film 21 of the piezoelectric vibrating reed 4 described later is omitted for the convenience of viewing the drawings.

[0057] like Figure 1 ~ Figure 4 As shown, the piezoelectric vibrat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap