Clutch arrangement and drivetrain arrangement for a multi-axle driven motor vehicle

A technology of coupling components and multi-shaft transmission, which is applied in the direction of mechanically driven clutches, transmissions, vehicle components, etc., and can solve problems such as high fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

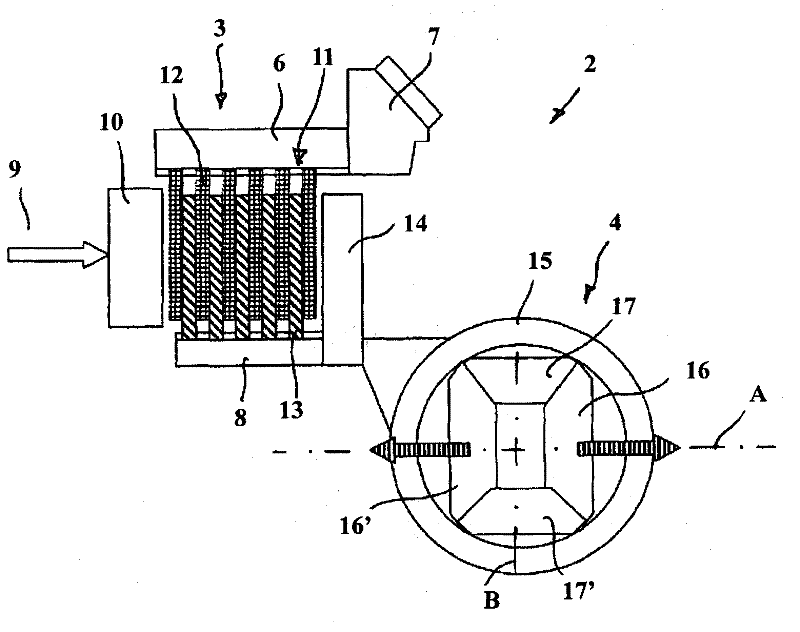

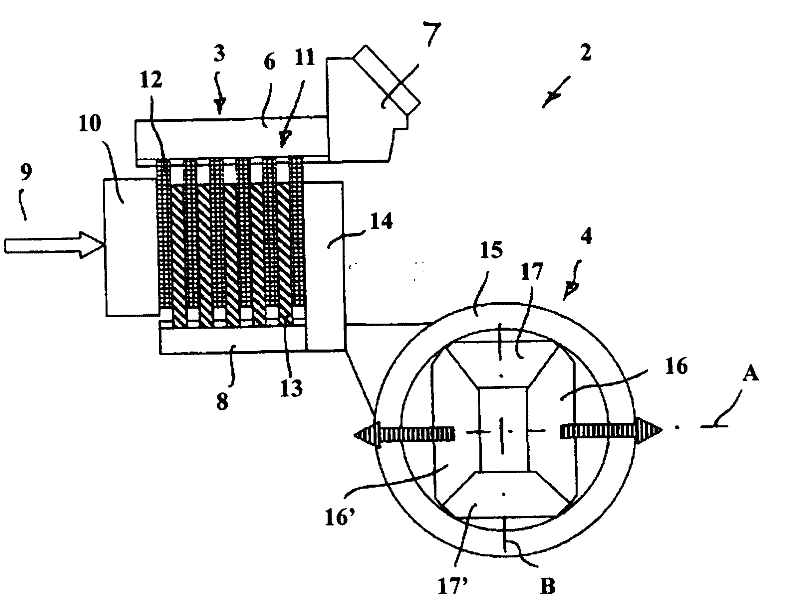

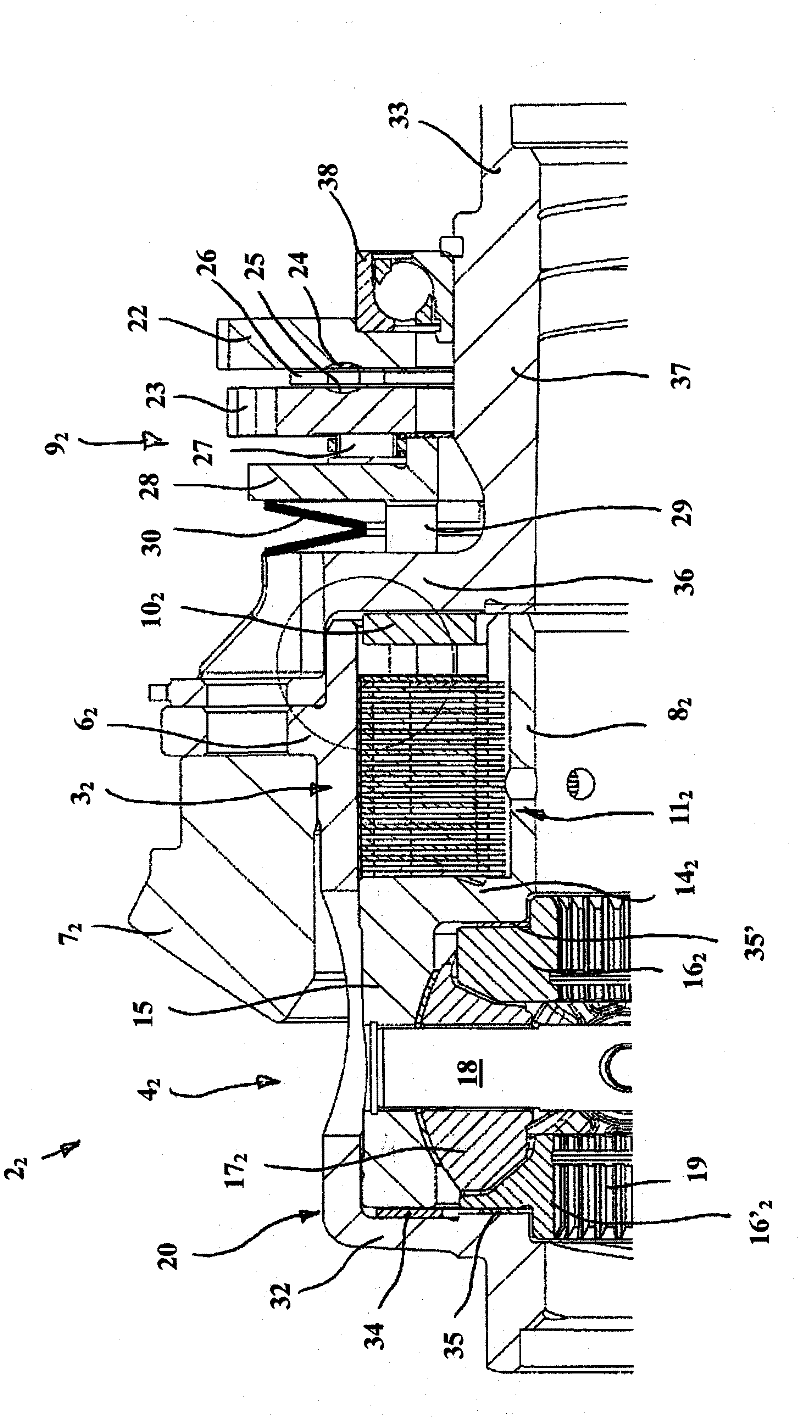

[0046] Figures 1 to 12 are first described together in view of their commonality. The coupling assembly 2 is shown respectively, and the coupling assembly 2 is used to connect the drive shaft to the longitudinal drive shaft of the motor vehicle or disconnect the drive shaft from the longitudinal drive shaft of the motor vehicle and adjust the action on the drive shaft as required Torque distribution. As an assembly, the coupling assembly 2 includes a friction coupling 3 and a differential transmission 4, which are connected in series in terms of torque flow. Among them, a switching coupling can also be provided between the friction coupling 3 and the differential transmission 4 41.

[0047] The friction coupling 3 includes a coupling input part 6 and a coupling output part 8. The coupling input part 6 is firmly connected with a crown gear (Tellerrad) 7 for introducing torque into the coupling assembly 2. The coupling The output member 8 is used to drive the differential transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com