Turbocharger

A technology of turbocharger and turbine rotor, which is applied in the direction of machine/engine, gas turbine device, supporting element of blades, etc., can solve the problems of reduced turbine efficiency, enlarged clearance, and large loss, and achieve the effect of improving turbine efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0077] The turbocharger of this embodiment is, for example, a variable capacity turbocharger capable of adjusting the flow velocity and flow angle of the exhaust gas supplied to the turbine rotor based on the increase or decrease of the gas flow rate accompanying the increase or decrease of the engine speed of the automobile. device. In addition, in each of the following drawings, in order to make each member a size that can be recognized in the drawing, the scale is appropriately changed for each member.

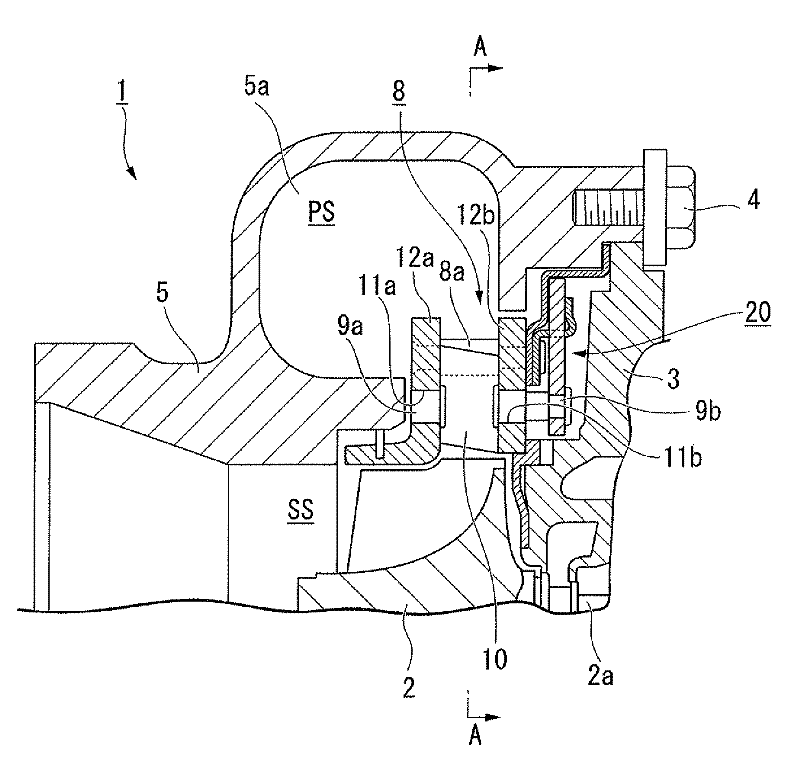

[0078] figure 1 It is a partially enlarged view of the cross-sectional view of the turbocharger of the present embodiment.

[0079] Such as figure 1 As shown, the turbocharger 1 of the present embodiment includes a bearing housing 3 that rotatably supports the turbine rotor 2 . A turbine housing 5 is integrally attached to one side of the bearing housing 3 (upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com