Holding device for a cast resin transformer winding

A technology of transformer winding and casting resin, which is applied in the direction of transformer/inductor coil/winding/connection, transformer/inductor parts, transformer/inductor core, etc., which can solve problems such as short leakage path and hindering environmental medium circulation , to achieve the effect of simple structure, reliable fixation and improved thermal characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

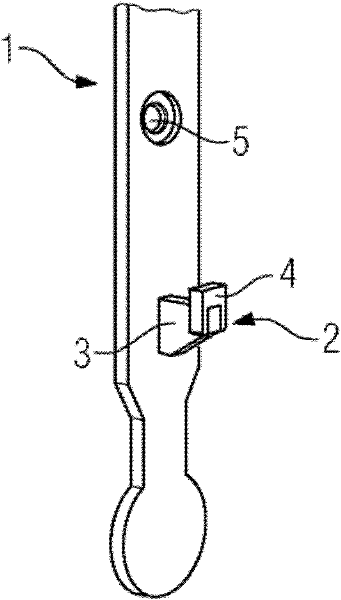

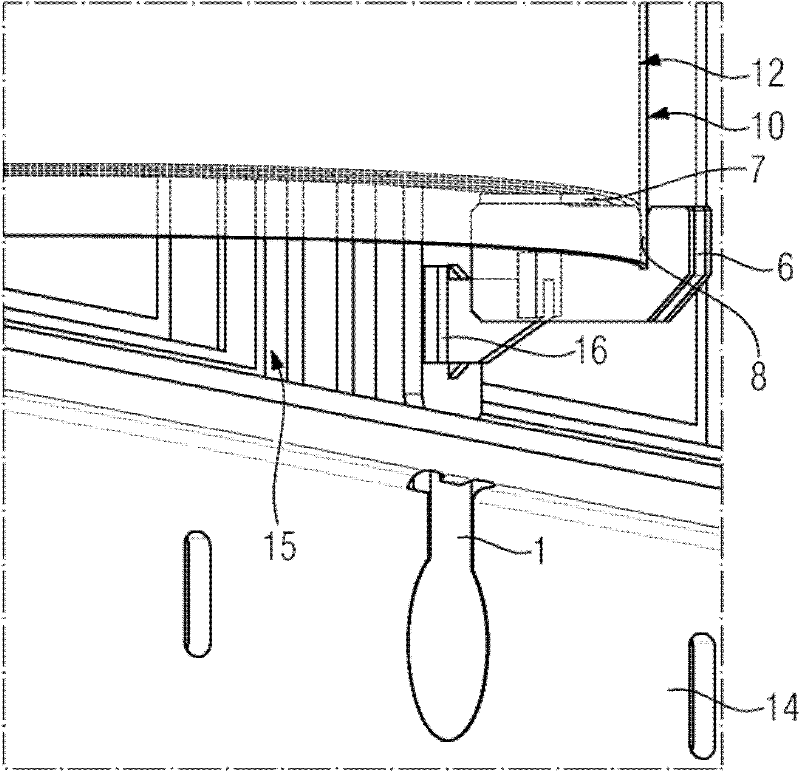

[0023] figure 1 A mast 1 according to the invention is shown with a receiving element 2 consisting of a web 3 and a fastening element 4 . Furthermore, the pole 1 has holes 5 through which bolts can pass and be connected to the transformer core. The web 3 of the receiving element 2 is welded to the pole 1 in the example shown. Other methods of connection, such as screwing or bonding, are also within the scope of the present invention. Fixing element 4 in figure 1 In the example shown, it can be plugged onto the web 3 of the receiving element 2 .

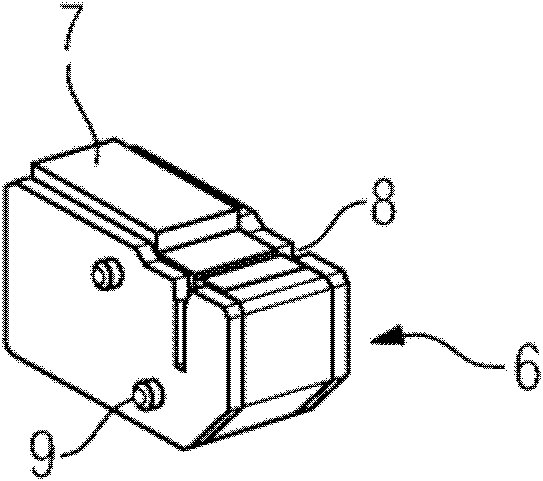

[0024] figure 2 A support element 6 is shown, which has a bearing surface 7 and a recess 8 . The cast resin transformer winding 12 can be arranged on the support surface 7 (not shown). The inner spacing of the recess 8 can be reduced by means of the locking element 9 . At the same time, the supporting element 6 can be fixedly connected to the receiving element 2 via the corresponding locking piece 9 . Furthermore, locking ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com