Gear type biomass fuel particle molding machine

A pellet molding machine, biomass fuel technology, applied in material molding press, die extrusion granulation, press and other directions, to achieve the effect of novel structure, reasonable design, long-term continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

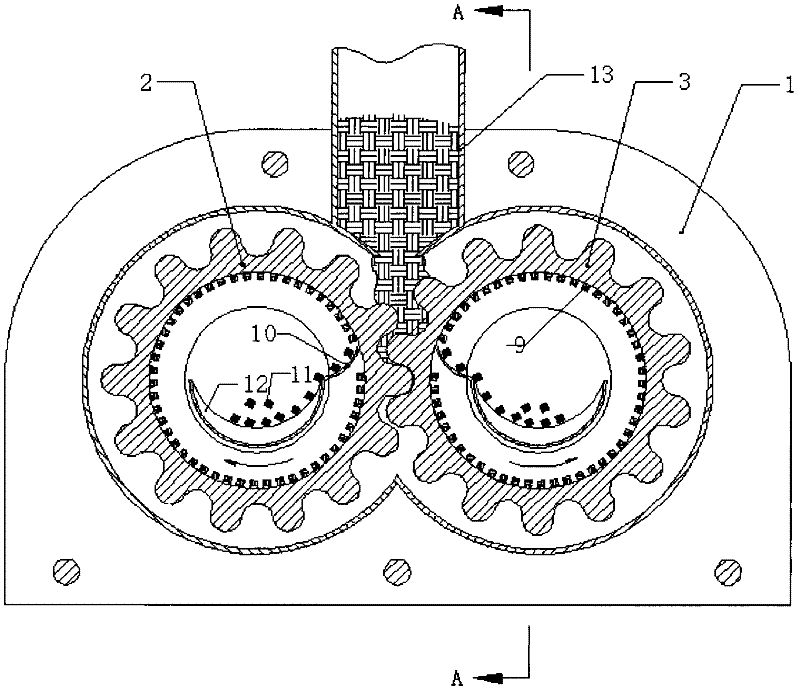

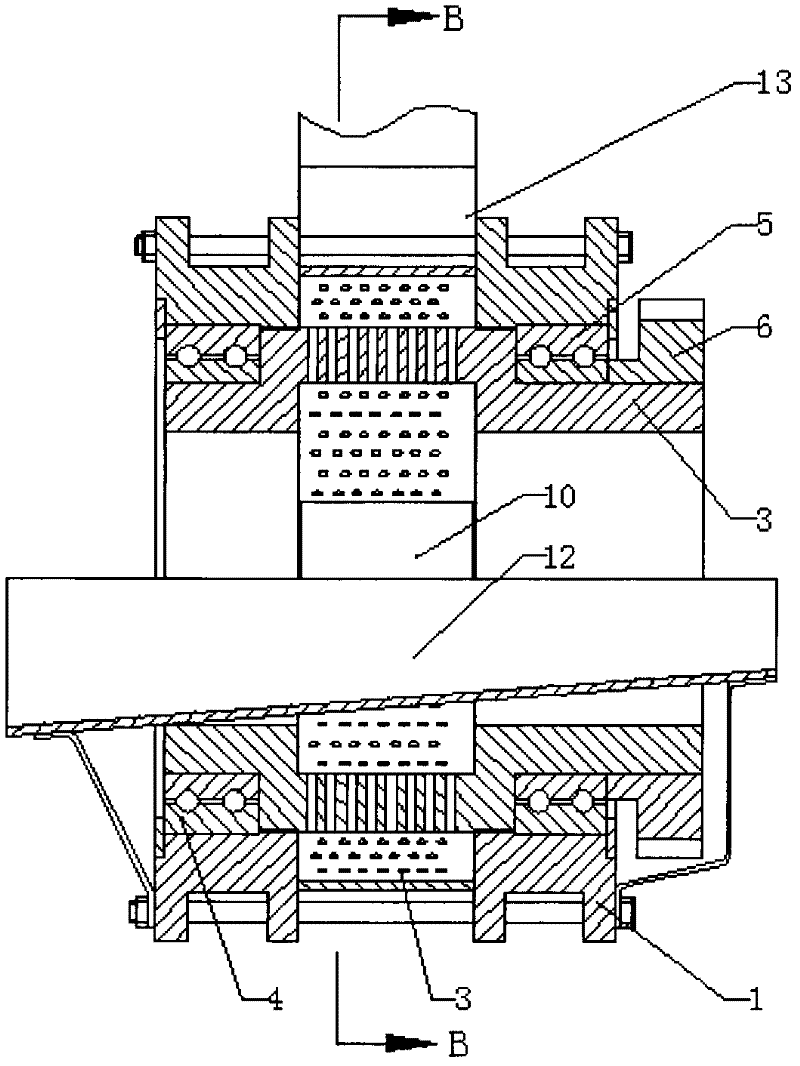

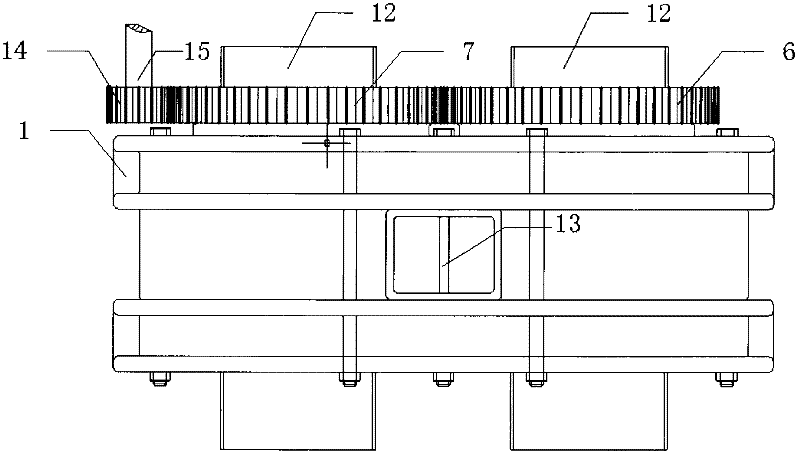

[0011] The patent of the present invention will be described in more detail below in conjunction with the accompanying drawings: the motor acceleration and decelerator transmits power to the pinion [14] on the shaft through the coupling, and then the pinion drives the bull gear 1 [7] and the bull gear 2 [ 6], because the gear type roller 1[2] is covered with a large gear 1[7] and bearing 1[5], and the gear type roller 2[3] is covered with a large gear 2[6] and bearing 2[4] ], so the power is finally transmitted to the geared pair of rollers 1 [2] and the geared pair of rollers 2 [3]. At the same time, the pulverized material is continuously fed into the The material is sent between the geared pair of rollers 1 [2] and the geared rollers 2 [3]. When the material enters the geared pair of rollers, it is subjected to the extrusion force and friction between the tooth root and the tooth top. The combined effect of shear force during operation makes the material continuously forced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com