Manufacturing method for X120 steel-level spiral seam hidden arc welding tube

A technology of submerged arc welded pipe and manufacturing method, which is applied in the direction of manufacturing tools, arc welding equipment, welding equipment, etc., can solve the problems of affecting the forming stability of steel pipes, large changes in the circumference and ellipticity of steel pipes, and insufficient deformation, etc., to achieve The matching of welding materials is scientific and reasonable, the welding parameters are scientific and reasonable, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The main chemical composition of the coil used for the X120 steel grade spiral submerged arc welded pipe in this example is shown in Table 1, and the mechanical properties are shown in Table 2. The thickness of the steel plate is 15.3mm, and the outer diameter of the steel pipe is F1420mm. The manufacturing process steps of the submerged arc welded pipe are as follows:

[0017] 1. The coil is uncoiled and leveled;

[0018] 2. Edge milling: first rough milling, milling off the width of the plate edge by 10-20mm; then fine milling the X-shaped groove, that is to say, the two butt plate edges of the steel plate coil are cut out with a blunt edge size of 5mm and a groove angle of 35° ° groove, the two sides of the steel plate are butted to form a 70° X-shaped groove;

[0019] 3. Pre-bending: pre-bend the delivery side and free side of the coiled plate on the two-roller bending machine, so that the radius size is 680mm; the length is 100-130mm, and the mouth is ≤1.0mm;

[...

Embodiment 2

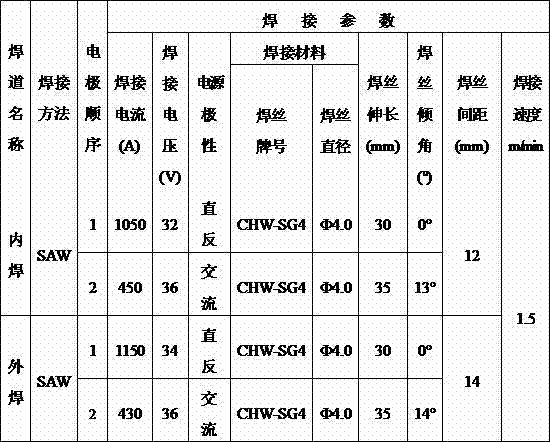

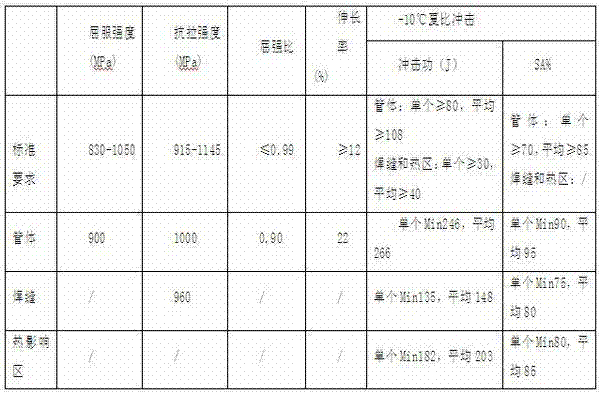

[0043] The main chemical composition and mechanical properties of the X120 steel grade coil used in the submerged arc welded pipe in this example are shown in Table 7 and Table 8. The thickness of the steel plate is 15.3mm, and the outer diameter of the steel pipe is F1420mm. The manufacturing process steps of the steel pipe are the same as those in Example 1, and the process parameters during welding are shown in Tables 9 and 10. Table 11 shows the main chemical composition of the weld metal in this example, and Table 12 shows the main performance test results of the steel pipe and the main performance requirements of the X120 steel grade spiral submerged arc welded pipe. It can be seen from the table that using The spiral welded pipe manufactured by the technology of the invention meets the technical requirements of the X120 steel grade spiral seam submerged arc welded pipe.

[0044] Table 7 Main chemical composition of coils (wt.%)

[0045] C mn Si P S B V...

Embodiment 3

[0058] The main chemical composition and mechanical properties of the X120 steel coil used in this embodiment are shown in Table 13 and Table 14. The thickness of the steel plate is 15.3mm, and the outer diameter of the steel pipe is F1420mm. The manufacturing process steps of the steel pipe are the same as those in Example 1, and the process parameters during welding are shown in Tables 15 and 16. Table 17 provides the main chemical components of the weld metal of this embodiment, and Table 18 provides the main performance test results of the steel pipe and the main performance requirements of the X120 steel grade pipeline steel pipe. It can be seen from the table that using the present invention The spiral welded pipe manufactured by the technology meets the technical requirements of X120 steel grade pipeline steel pipe.

[0059] Table 13 Main chemical composition of coils (wt.%)

[0060] C mn Si P S B V+Nb+Ti Ni+Cr+Cu Cr+Mo+Mn CE ⅡW CEpcm 0.05...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com