Linkage type tool magazine tool changing device

A tool changing device and linkage technology, which is applied in positioning device, clamping, supporting and other directions, can solve problems such as elastic fatigue, affecting accuracy, and easy fatigue of torsion springs, etc., so as to achieve not easy elastic fatigue, fast tool changing response, and stable noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

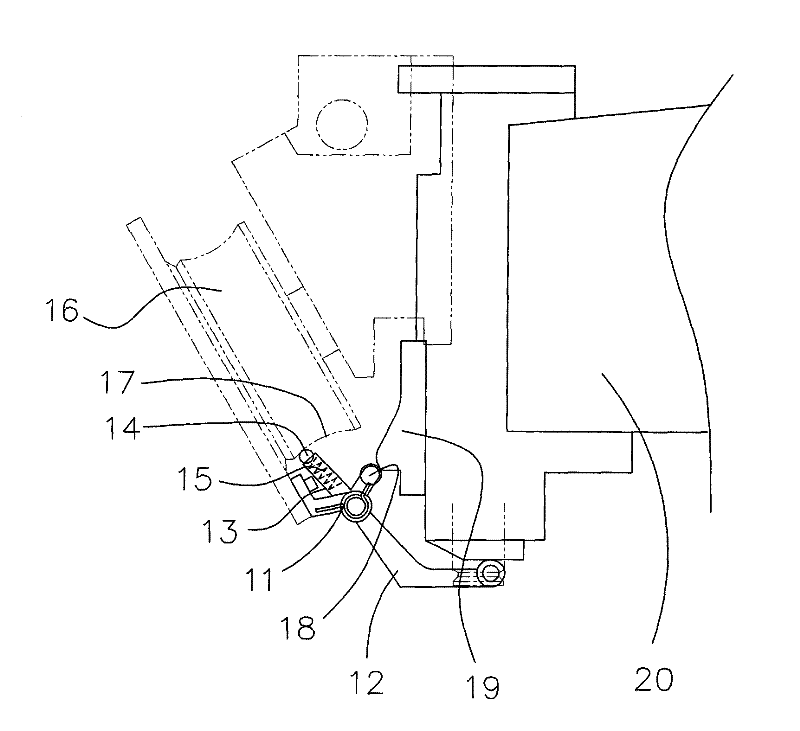

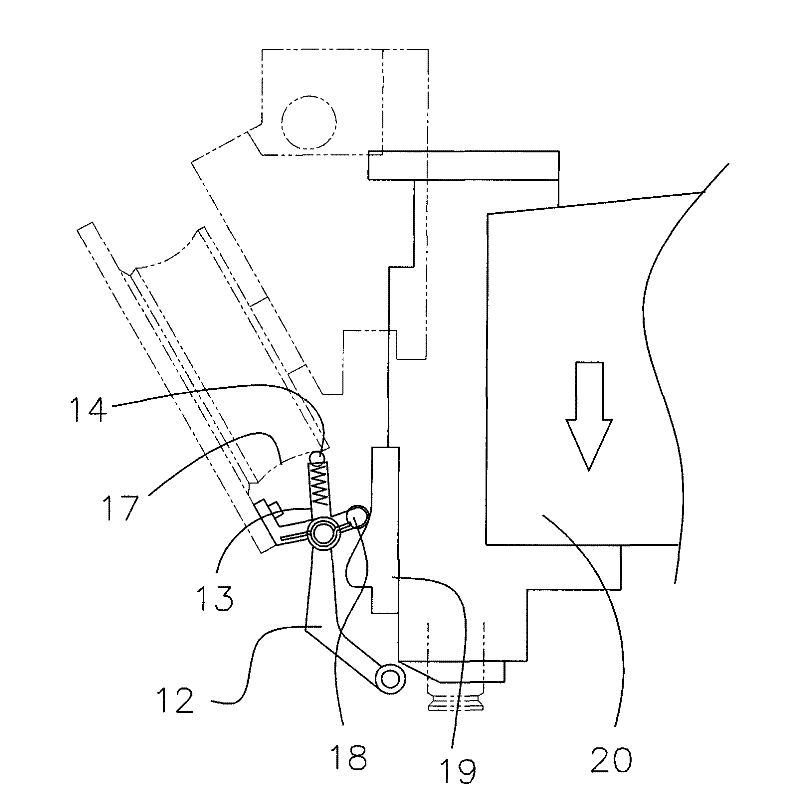

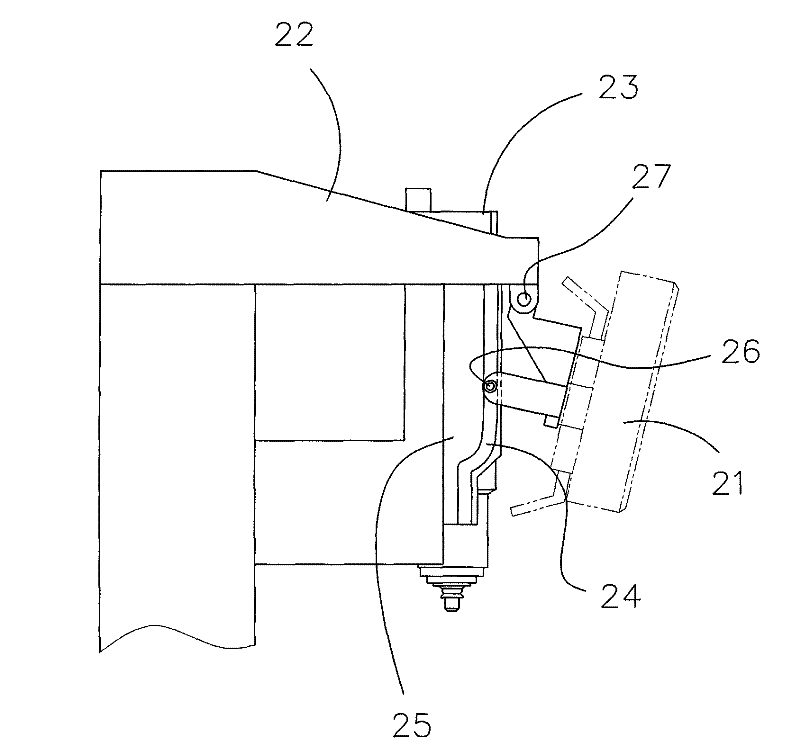

Embodiment Construction

[0059] see image 3 , the figure shows that the spindle headstock 30 of the machine tool is adjacent to a tool magazine 40; the tool magazine 40 has a rotating disk 41, and several tool clamping arms 42 are set on the rotating disk 41 (a tool clamping arm is shown in the figure) ; In particular, the tool clamp arm 42 has a base 43 and a swing arm 44, wherein the base 43 is fixed on the rotary cutter head 41, and the swing arm 44 is swingably configured on the base 43; there is also a torsion spring 45 It is arranged on the swing arm 44 of the tool holder arm 42 , one end of which can be fixed to the base 43 , and the other end can be fixed to the swing arm 44 . One end of the above-mentioned tool clamp arm 42 is opposite to the spindle headstock 30 and is used to clamp a tool handle (not shown); the tool clamp arm 42 is further matched with a guide plate 50 so that the swing arm 44 of the tool clamp arm 42 can swing to The tool handle is inserted into or withdrawn from the sp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap