Concrete spreader

A technology of placing machine and concrete, which is applied to unloading devices, ceramic molding machines, manufacturing tools, etc., can solve the problem that the concrete is easily scattered outside the steel mold of the pipe pile and the mold clamping part, and the concrete supply and energy consumption cannot be effectively controlled. The problem of high wear and tear of Jiaolong can achieve the effect of small power, low cost of use and small viscous effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

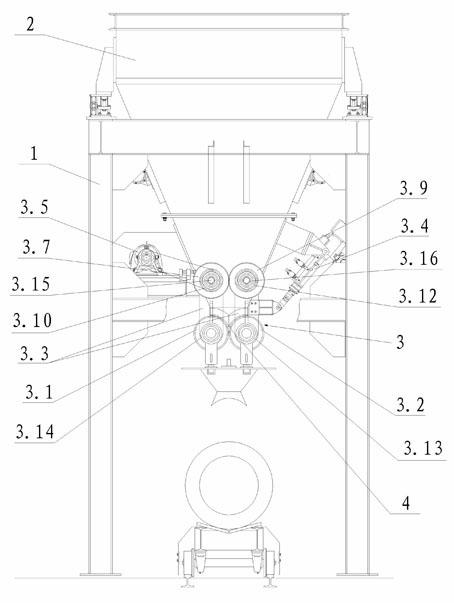

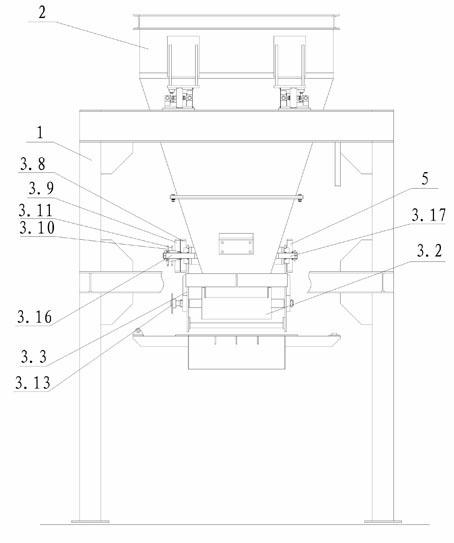

[0018] Such as figure 1 , figure 2 , image 3 with Figure 4 The shown concrete placing machine comprises a support 1 and a hopper 2 connected to the support 1, the lower end of the hopper 2 is provided with a discharge port 4, and the discharge port 4 is provided with an accelerated feeding device 3. Of course, the concrete placing machine also includes other parts, but these parts are all the same as the prior art concrete placing machine, and the invention points of the present invention are not involved, so it is not repeated here.

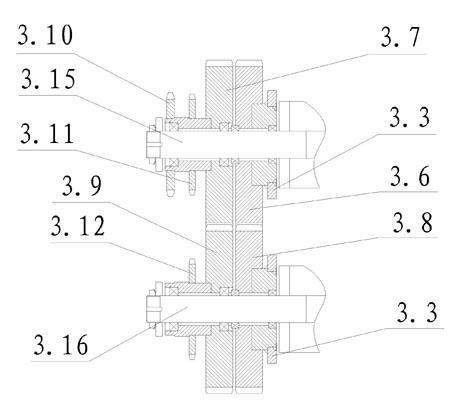

[0019] Described accelerated unloading device 3 comprises the motor 3.5 that is installed on the bracket 1 and the first unloading roller 3.1 that is connected in hopper 2 outlet 4 and the second unloading roller 3.2 of rotation, and described motor 3.5 is connected with the first unloading roller. A tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com