Integrated patch unit

A patch and luminous body technology, applied in the direction of electrical components, electric solid-state devices, semiconductor devices, etc., can solve the problems of complex circuit structure of full-color light-emitting units, light-emitting elements, driver chips and peripheral components that cannot be mounted as a whole, etc. Achieve the effect of mass production and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

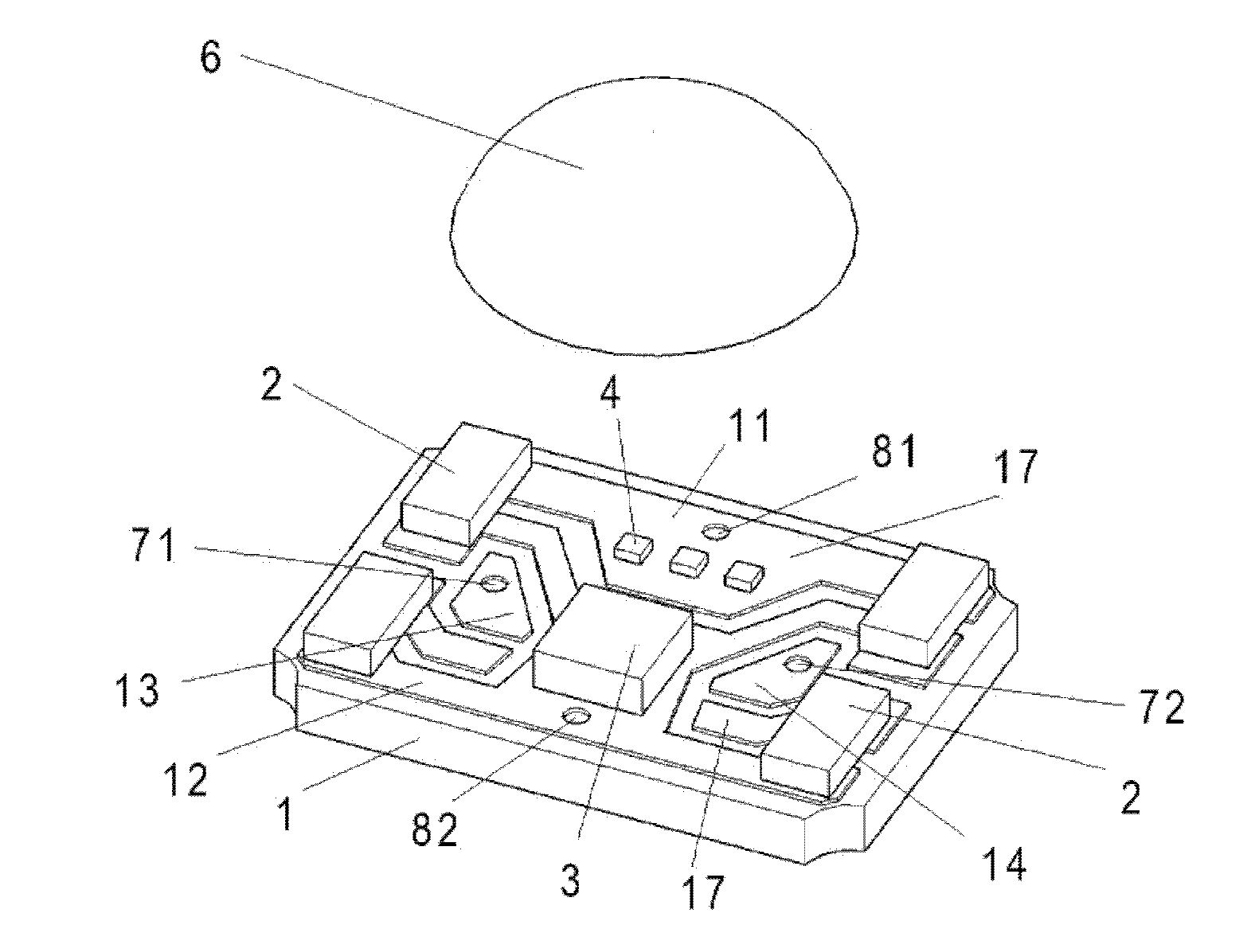

[0050] see figure 1 The integrated patch unit provided in this embodiment includes a circuit substrate 1, and the circuit substrate 1 at least includes a top circuit layer 17 and a bottom circuit layer (ie, Figure 13 The shown bottom circuit layer 18 is collectively referred to as "bottom circuit layer 18" hereinafter for convenience of description). The bottom circuit layer 18 functions as component patch leads, so it is also called a lead layer. The top circuit layer 17 is provided with peripheral components 2 , one power pole 11 , the other power pole 12 , signal input pole 13 , signal output pole 14 , luminous body 4 and driver chip 3 . details as follows:

[0051] One pole 11 of the power supply, the other pole 12 of the power supply, the signal input pole 13 and the signal output pole 14 are electrically connected to the bottom circuit layer 18 respectively; the luminous body 4 is electrically connected to the one pole 11 of the power supply; The signal output pole ...

Embodiment 2

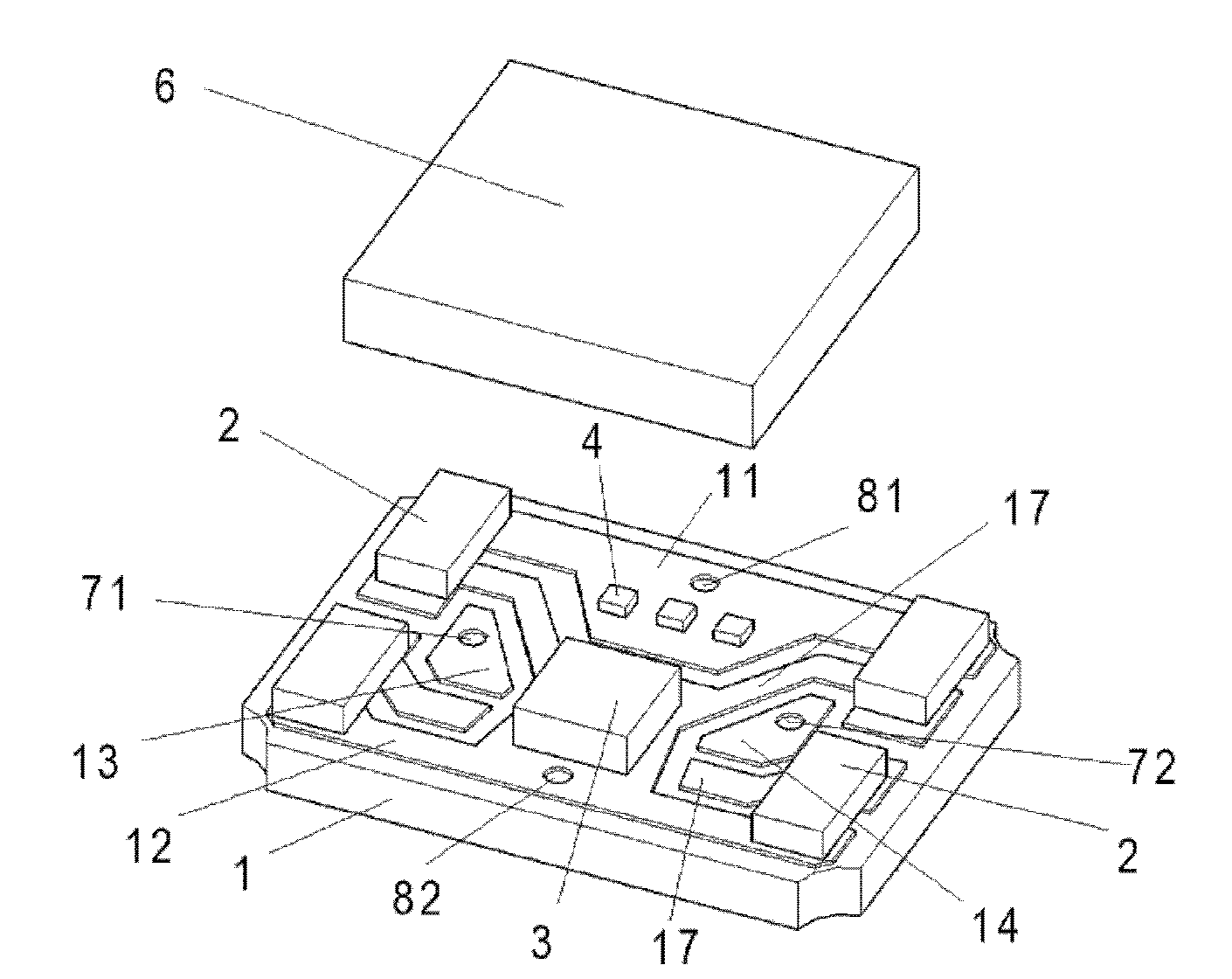

[0066] see image 3 , Figure 4 Compared with the above-mentioned first embodiment, the integrated patch unit provided in this embodiment differs in that: a dam 5 for potting and encapsulating the packaging material 6 is provided on the top circuit layer 17, and the dam 5 is used for The peripheral components 2 are isolated from the driving chip 3 and the luminous body 4 . An encapsulation groove 15 is formed in the dam 5 and on the top circuit layer 17 , and the encapsulation material 6 is poured into the encapsulation groove 15 .

[0067] Such as image 3 As shown, the dam 5 is a polygonal dam or an annular dam (for convenience of description, hereinafter, "polygonal dam or annular dam" is collectively referred to as a polygonal dam) by connecting several dams 51 end to end. Such as Figure 4 As shown, the polygonal dam is bonded on the circuit substrate 1 . The packaging groove 15 is formed on the circuit substrate 1 and is located in the dam 5; the driving chip 3 and ...

Embodiment 3

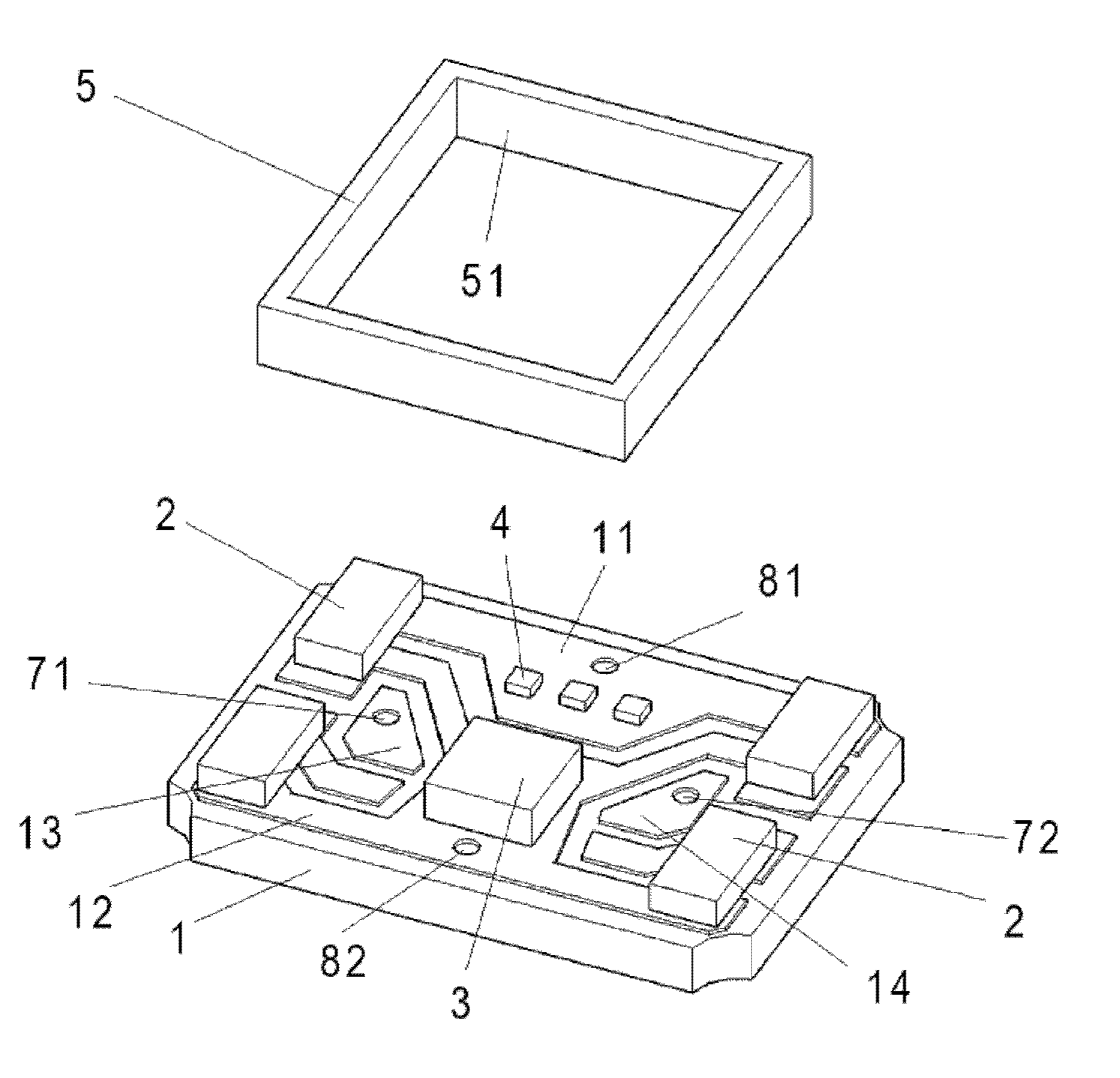

[0070] see Figure 5 , Figure 6 Compared with the above-mentioned second embodiment, the integrated patch unit provided by this embodiment is different in that: the dam 5 is provided with a positioning rod 55, and the conductive via hole 81 and the conductive via hole on the circuit board 1 are used to 82 as positioning holes.

[0071] Such as Figure 6 As shown, the locating rod 55 is connected with the dam 5 as a whole, and when the dam 5 and the circuit substrate 1 are mounted, the locating rod 55 is embedded on the circuit substrate 1; and the locating rod 55 is aligned with the positioning hole on the circuit substrate 1, so that The dam 5 is accurately attached to the circuit substrate 1 .

[0072] In this embodiment, the conductive vias 81 and 82 at the two poles of the power supply are used as positioning holes, and the positioning holes not only function as conductive vias, but also serve as positioning for the dam 5 . During specific implementation, the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com