Preparation method of cathode material and application of cathode material in microbial fuel cell

A cathode material, fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., to achieve the effects of simple activation method, reduced construction cost, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

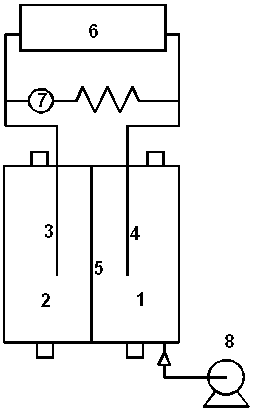

Method used

Image

Examples

Embodiment 1

[0037] Step 1: Preparation and Characterization of Strong Acid-Activated Graphite Materials

[0038] (1) Clean a graphite rod with a diameter of 6 mm and 200 mL of graphite particles with a particle size of 5×4 mm with deionized water and ethanol, and air-dry. At 30°C, soak the pretreated graphite rods and graphite particles in 85% phosphoric acid for 12 hours, then rinse them with deionized water, and dry them in the air.

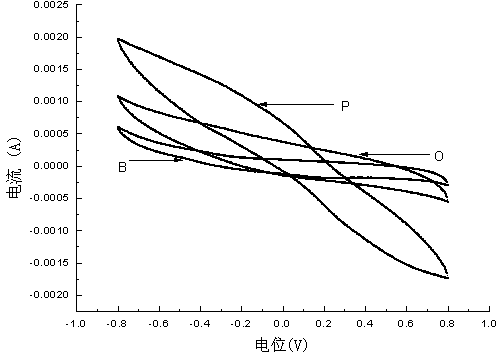

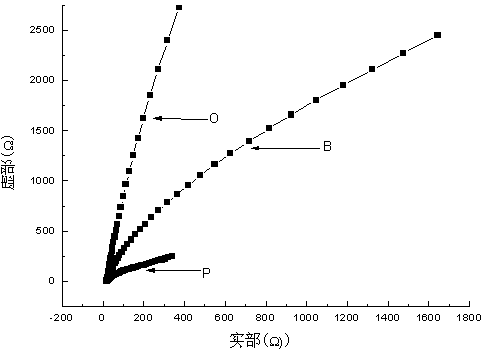

[0039] (2) Electrochemical tests were performed on graphite electrodes before and after activation: Electrochemical tests were carried out on chemically activated electrodes using a traditional three-electrode system, that is, Parstat 2273 electrochemical workstation was used at room temperature, and 50mM phosphate buffer solution (PBS ) as the electrolyte, with the calomel electrode (Hg / HgO electrode) as the reference electrode, the platinum electrode as the auxiliary electrode, and the activated electrode as the working electrode, the cyclic voltammetry ...

Embodiment 2

[0049] Step 1: Preparation and Characterization of Strong Acid Activated Graphite Materials

[0050] (1) Clean a graphite rod with a diameter of 6 mm and 200 mL of graphite particles with a particle size of 5×4 mm with deionized water and ethanol, and air-dry. At 30°C, soak graphite rods and 200mL graphite particles in 5mol / L nitric acid solution for 36h, then rinse with deionized water and dry in the air.

[0051] (2) Electrochemical tests were performed on the graphite electrodes before and after activation. The electrochemical test shows that the oxygen reduction current of the graphite electrode activated by nitric acid is significantly greater than that of the unactivated electrode in the cyclic voltammetry test, indicating that the oxygen reduction ability of the activated electrode is enhanced (see figure 2 ).

[0052] (3) Using Nicolet Fourier transform infrared spectrometer, FTIR results (see Figure 4 ) shows that the nitric acid activated graphite material is at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com