Heating wire for lighter

A technology of electric heating wire and lighter, which is applied in the direction of ohmic resistance heating parts, combustion ignition, heating elements, etc., which can solve the problems that cannot guarantee fast ignition and achieve the effect of convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

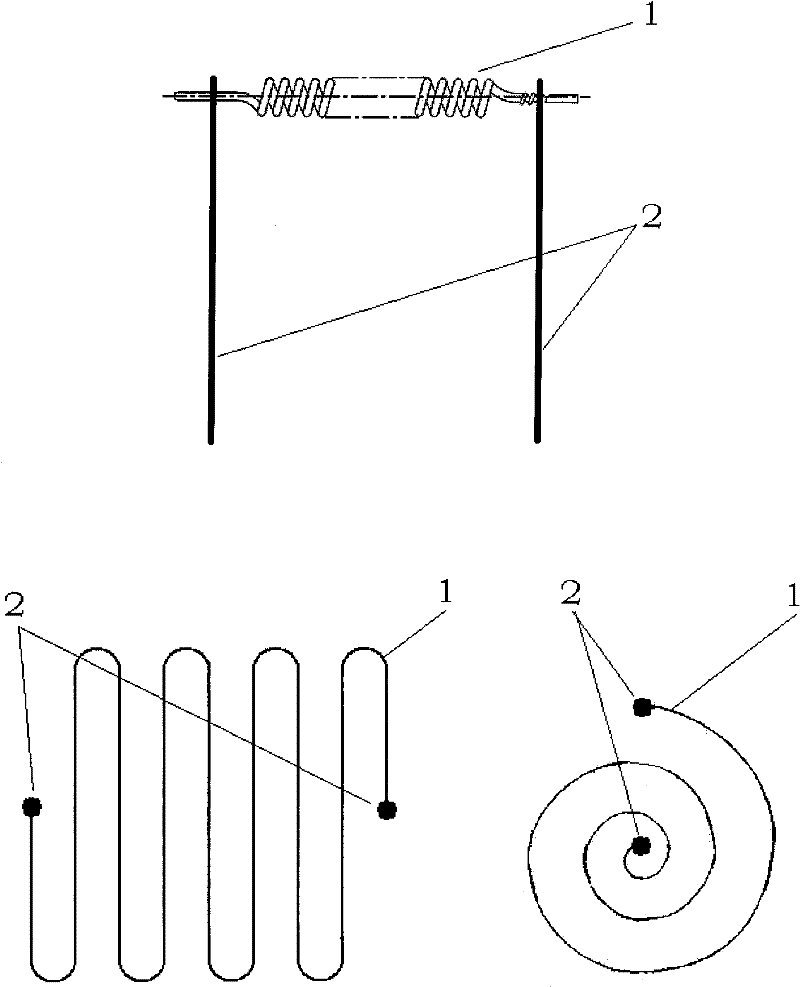

[0014] refer to figure 1 According to the cold resistance of 1.7-45Ω, the electric heating wire 1 is wound into a spiral structure to make a linear or planar shape, or made of a flat electric heating wire. The best cold resistance is 6-13Ω, and the two ends are respectively connected to two metal One end of the rod 2 is made into an integral puller by welding or cold pressing.

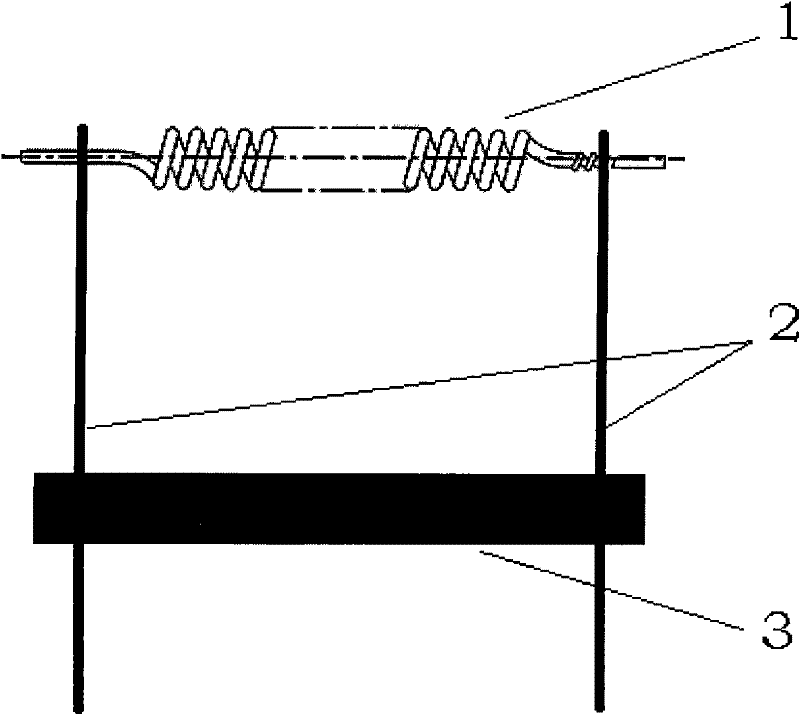

[0015] figure 2 The two metal rods 2 shown can also be made to be placed separately in parallel, and an "H" shape fixed by an insulator 3 is horizontally placed in the middle, and then a pull-out plug-in unit fixed with the two ends of the heating wire 1 as one.

[0016] The metal rod 2 is fixed with the heating wire 1 and is plugged and connected with the lighter so that the heating wire 1 is connected to the circuit, which is convenient for use and maintenance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com