Column-beam connection structure

A technology for joints and columns and beams, applied in welding equipment, building structures, welding/welding/cutting items, etc., can solve the problems that the beam web cannot be expected to bear, and achieve increased plate thickness, prevention of embrittlement, and bending moment bearing big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Embodiments of the present invention will be described below.

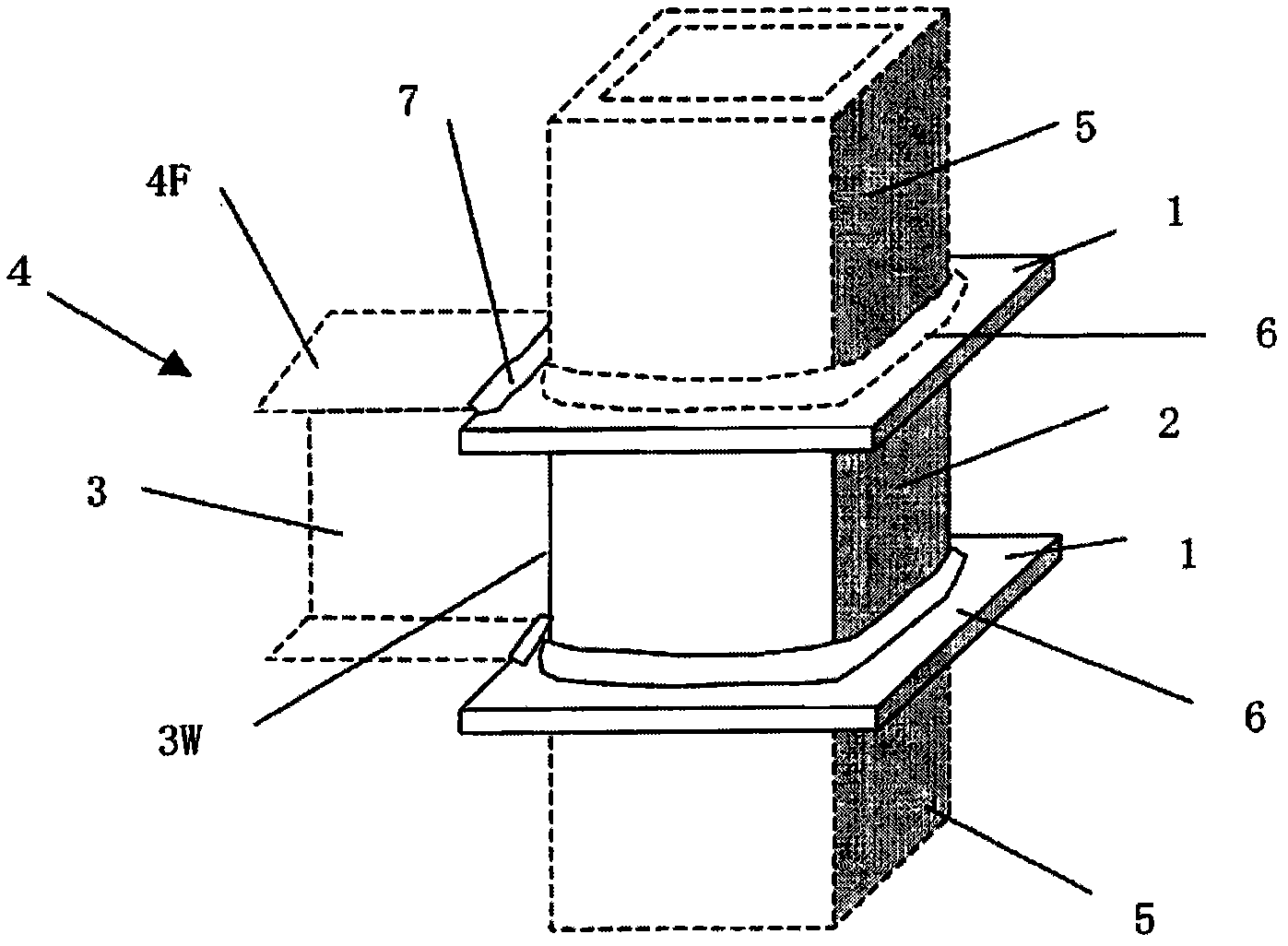

[0044] As an example of the embodiment of the present invention described in claim 1, Figure 5 It shows an example of removing the protrusion of the partition plate 1 from the column 5 in the column-beam junction of the building steel frame, increasing the thickness 1t of the partition plate 1, and connecting the column shaft 5 and the welded part 7 of the partition plate 1 and the beam flange 4F It overlaps and joins with the welded part 7 of the separator 1, and welds at least the thickened part of the separator 1 that increases by 5 mm or more, preferably 35 mm or more, to the web of the beam. In the case of increasing the thickness of the partition to 1 / 2 of the height of the web, it is possible to use a structure that integrates the upper and lower partitions, or weld the middle of the two partitions to omit the middle column short tube .

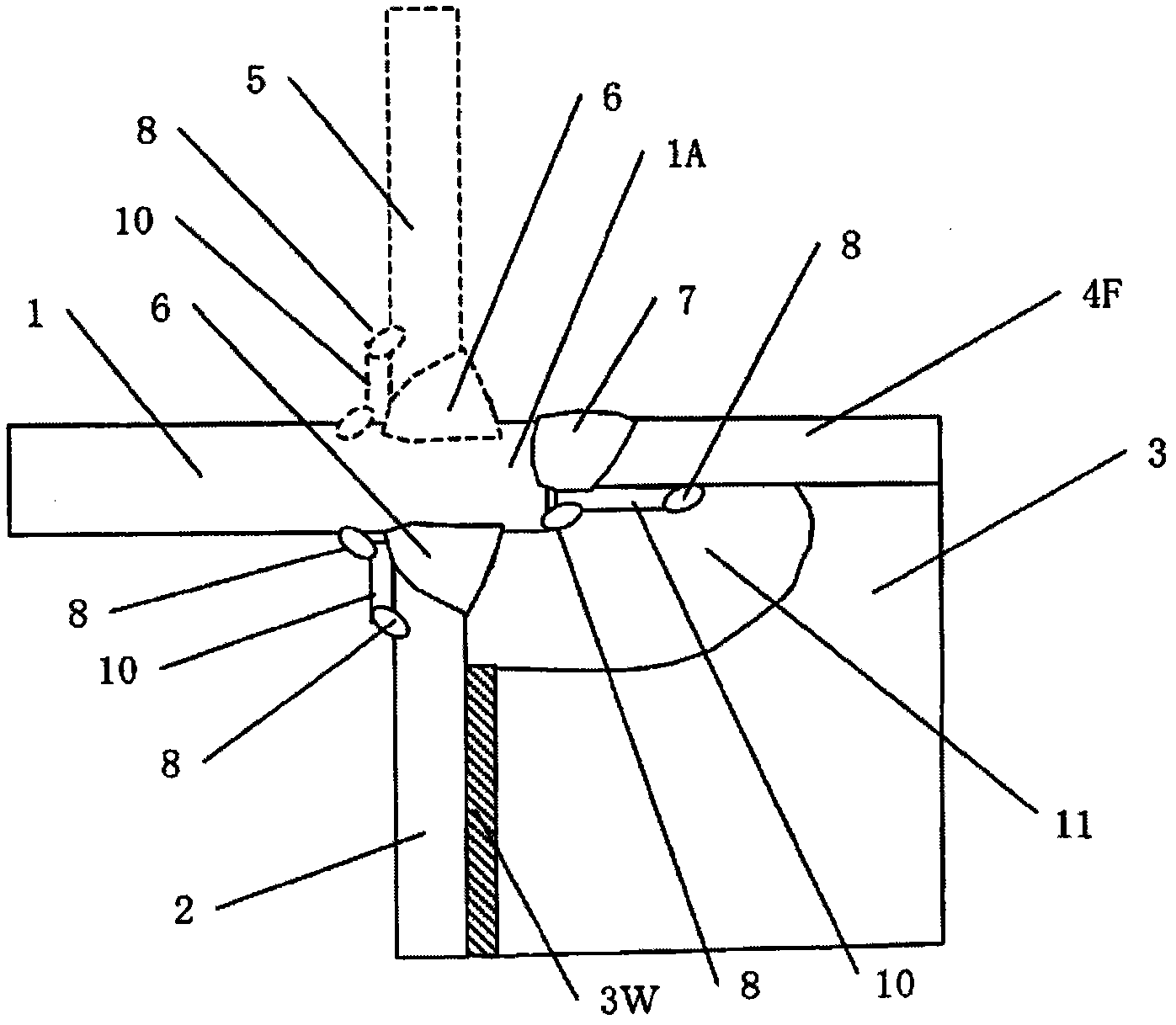

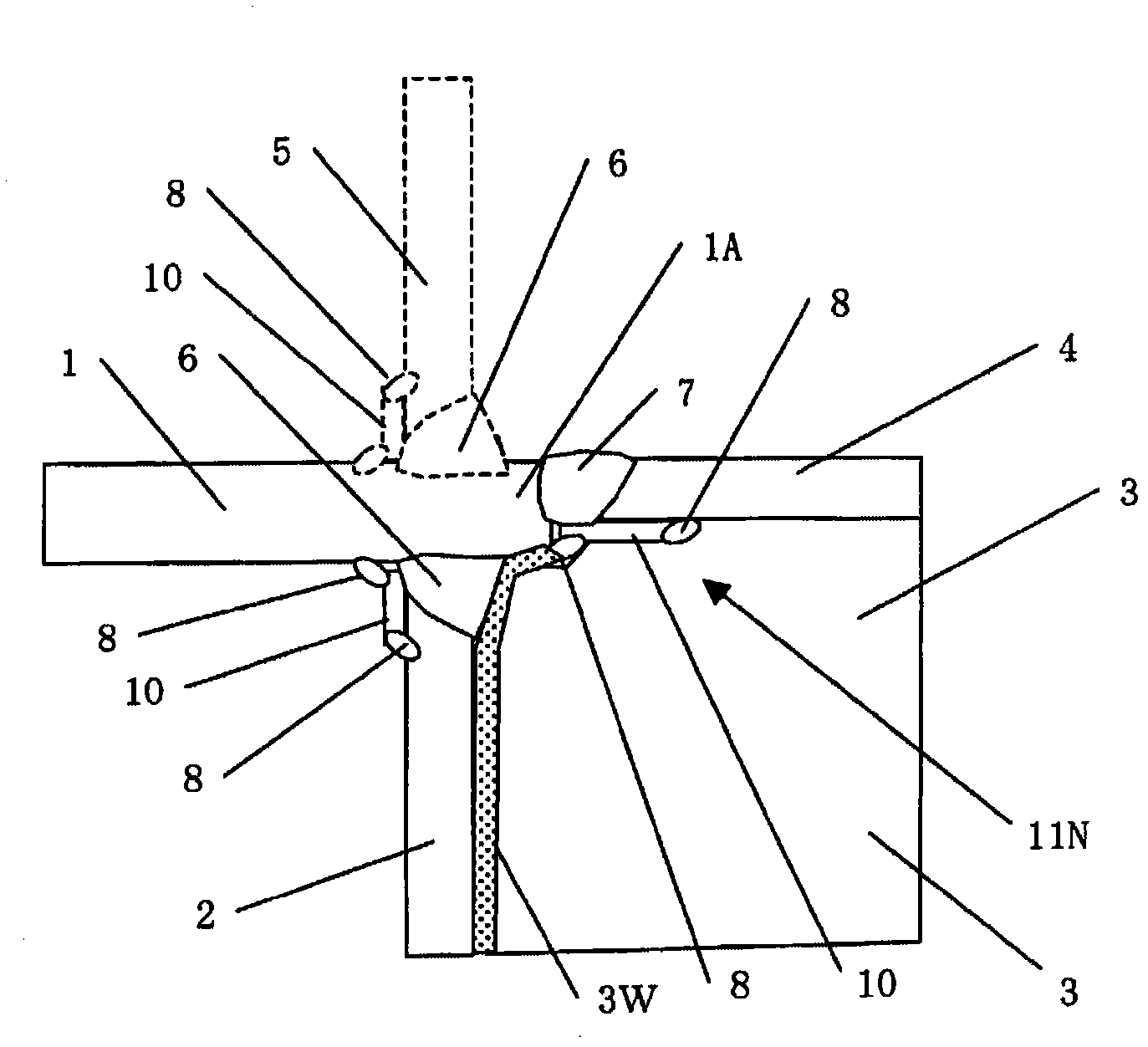

[0045] Such as Figure 6 As shown, as an example of the em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com