Fixture for turning stator core of wind-driven generator

A core turning and machine stator technology, which is applied in the field of wind turbine stator core turning fixtures, can solve the problems of unsatisfactory production requirements, complicated calibration and positioning operations, and unstable processing quality, so as to reduce the amount of workpiece turnover and alleviate equipment bottlenecks Stress, the effect of increasing labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

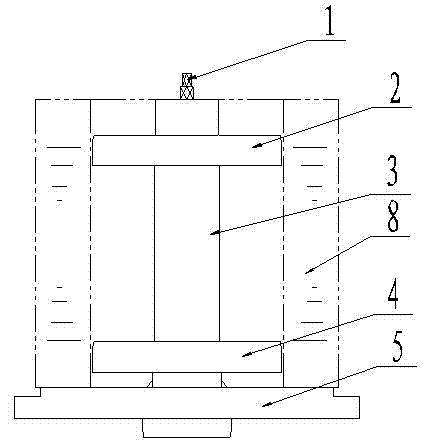

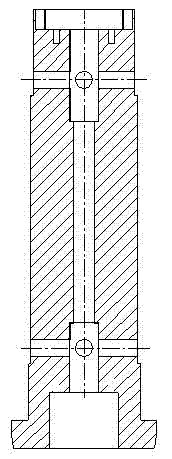

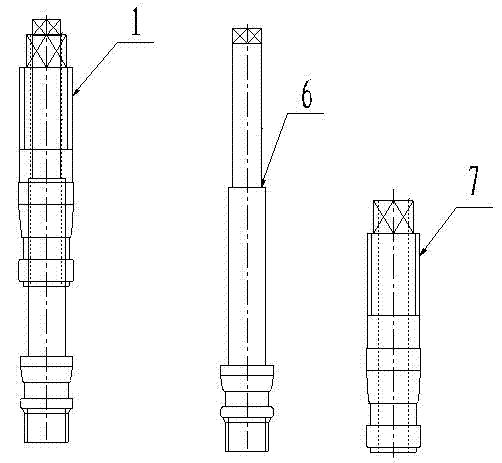

[0012] Such as figure 1 , figure 2 , wind power generator stator core turning fixture, which includes a main shaft 3, a base 5, a relay shaft 4, a support ring 2 and a screw shaft 1, the screw shaft 1 is assembled on the main shaft 3 through a rotating device and a locking cover plate, and the starting power source or With the function of the applied force point, the support ring 2 is welded into a whole by the positioning support ring and the anti-deformation support plate, and then welded together with the main shaft 3 through the positioning and matching method of the support ring seam. Parts function and automatically cooperate with the working platform of the vertical lathe. The relay shaft 4 is equipped with an elastic device. The relay shaft 4 is installed on the main shaft 3. The upper elastic device finely adjusts, positions and locks the stator core on the circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com