Automatic oilstone feeding device of portable plastic mould conformal-polishing machine

A plastic mold and automatic feeding technology, which is applied to surface polishing machine tools, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of mechanical polishing without vitality, different wear rates, and difficult feeding of oil stones, etc., to overcome The effect of difficult automatic feeding, simple structure and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

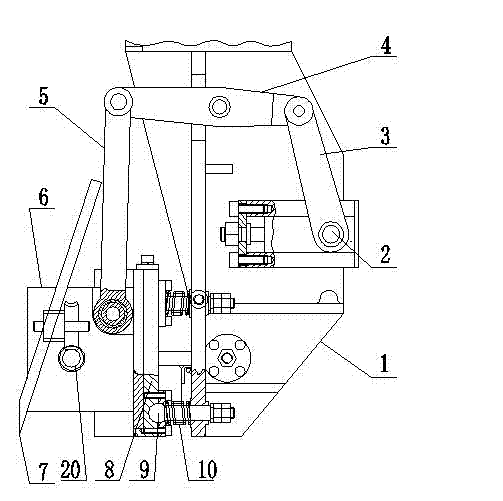

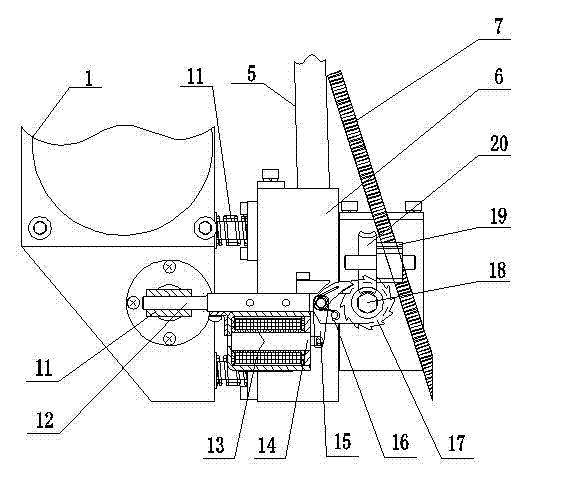

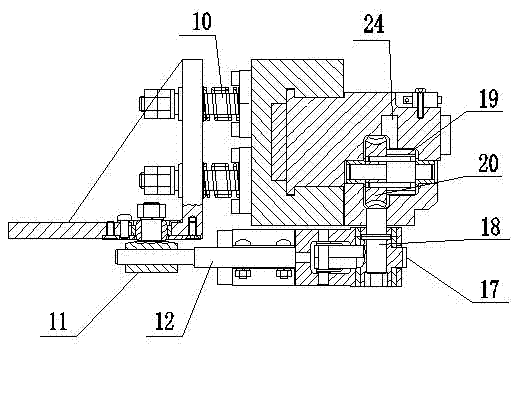

[0019] see Figure 1 to Figure 5 , a portable oil stone automatic feeding device for a plastic mold follow-up polishing machine, which includes a frame 1, a hinged rocker 4 on the frame 1, the two ends of the rocker 4 are respectively hinged with a connecting rod A3 and a connecting rod B5, and the connecting rod A3 articulated crank 2, connecting rod B5 articulated slide block 6, slide block 6 is looped on T-shaped slide seat 8, T-shaped slide seat 8 is movably connected with frame 1 through several support rods 9 with ball heads, and the support rods The compression spring 10 is set on 9; at least two bearings 23 are embedded in the inner cavity of the slider 6, and the bearings 23 are set on the bearing position of the worm 18; End-mounted ratchet 17, ratchet 17 looper swing rod 12, swing rod 12 is inserted into the rocker 11 on the frame 1, swing rod 12 is connected to electromagnet 13, electromagnet 13 is provided with iron core 14, iron core 14 The rocker arm of the rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com