Method for synthesizing unsaturated polyester resin for artificial marble

A technology of artificial marble and polyester resin, applied in the synthesis field of unsaturated polyester resin, which can solve the problems of large curing shrinkage rate, fast curing heat release at room temperature, general boiling water resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

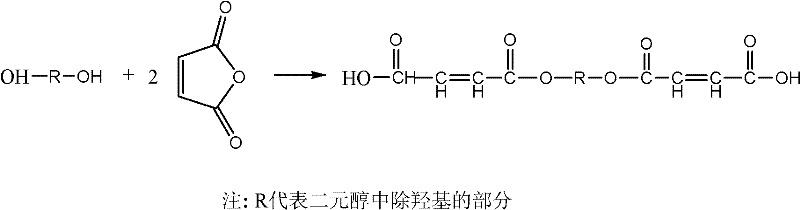

Method used

Image

Examples

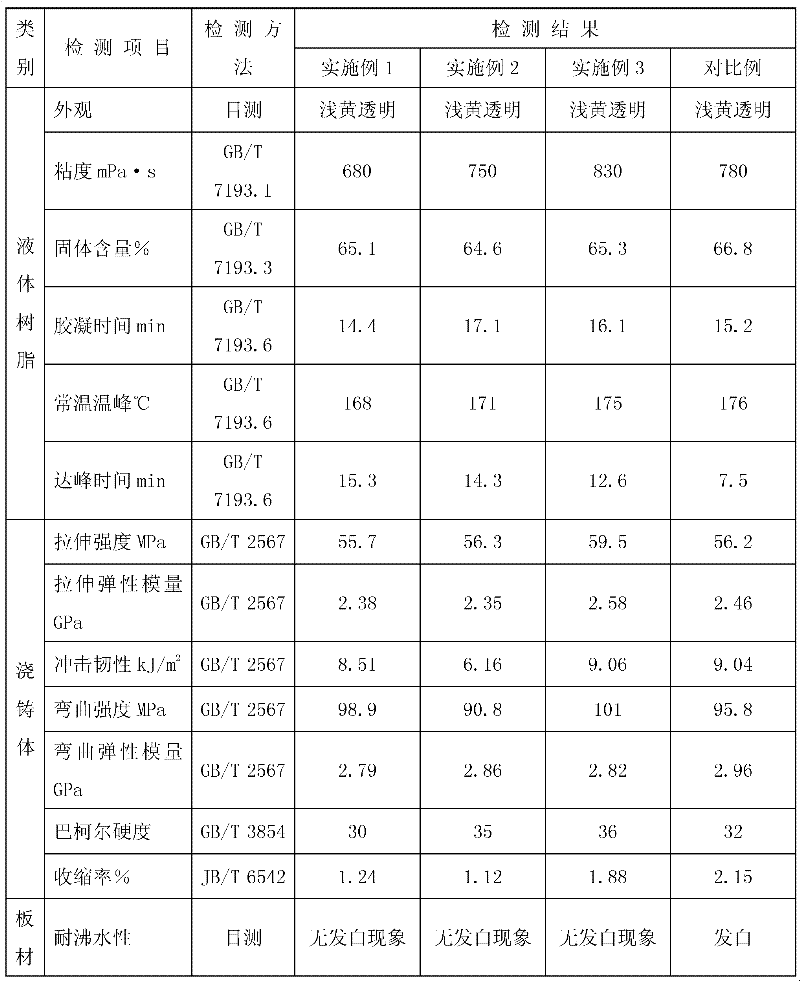

Embodiment 1

[0031] In a 2L four-necked flask with a thermometer, stirrer, nitrogen inlet tube and reflux condenser, add 382g diethylene glycol, 588g maleic anhydride and 459g dicyclopentadiene (technical grade, purity is 78- 85%), under the protection of nitrogen, the temperature was raised to 140° C. for reflux reaction for 3 hours, and then the temperature was rapidly raised to 160° C. for reflux reaction until the acid value reached 160 mgKOH / g. Then change the system to a distillation state, add 167g of ethylene glycol, gradually raise the temperature to 205°C and keep warm for further polycondensation until the acid value reaches 55mgKOH / g, and when the water output reaches 85% of the theoretical value, vacuumize to force the water out , make the reaction to an acid value of 25mgKOH / g. Cool down to 190°C, add 0.1g of hydroquinone, stir evenly, cool to 120°C, add 800g of styrene to dilute. Cool and filter to obtain light yellow transparent viscous liquid.

Embodiment 2

[0033] In a 2L four-necked flask with a thermometer, stirrer, nitrogen inlet tube and reflux condenser, add 168g ethylene glycol, 530g maleic anhydride, 70g fumaric acid and 286g dicyclopentadiene (technical grade) successively , with a purity of 80-85%), under the protection of nitrogen, the temperature was raised to 145° C. for reflux reaction for 3 hours, and then the temperature was rapidly raised to 165° C. for reflux reaction until the acid value reached 280 mgKOH / g. Then change the system to a distillation state, add 350g of diethylene glycol, gradually raise the temperature to 200°C, and keep warm until the acid value reaches 50mgKOH / g. To acid value 25mgKOH / g. Cool down to 195°C, add 0.1g of hydroquinone, stir evenly, cool to 125°C, add 700g of styrene to dilute. Cool and filter to obtain light yellow transparent viscous liquid.

Embodiment 3

[0035] In a 2L four-necked flask with a thermometer, a stirrer, a nitrogen inlet tube and a reflux condenser, add 137g propylene glycol, 471g maleic anhydride and 293g dicyclopentadiene (industrial grade, with a purity of 80-85%) successively ), under the protection of nitrogen, the temperature was raised to 142° C. for reflux reaction for 3 hours, and then the temperature was rapidly raised to 160° C. for reflux reaction until the acid value reached 150 mgKOH / g. Then change the system to a distillation state, add 412g of diethylene glycol and 178g of phthalic anhydride, gradually raise the temperature to 210°C, keep warm until the acid value reaches 55mgKOH / g, and then vacuum until the acid value reaches 20mgKOH / g. Cool down to 195°C, add 0.1g of hydroquinone, stir evenly, cool to 120°C, add 780g of styrene to dilute. Cool and filter to obtain light yellow transparent viscous liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com