Slubby yarn and production method thereof

A technology of slub yarn and slub, which is applied in the direction of yarn, spinning machine, textile and paper making, etc. It can solve the problems of weak twist of slub segments, large strength unevenness, and single style, so as to reduce costs and improve quality , The effect of small product volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

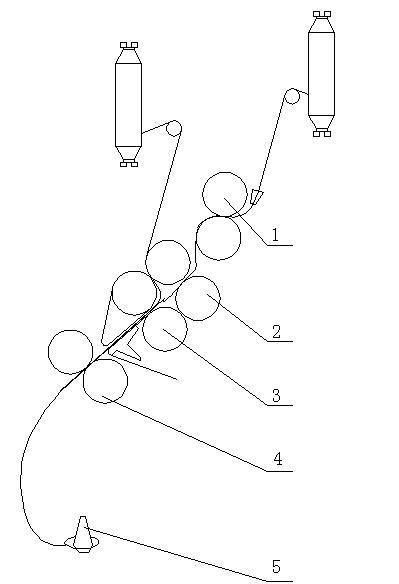

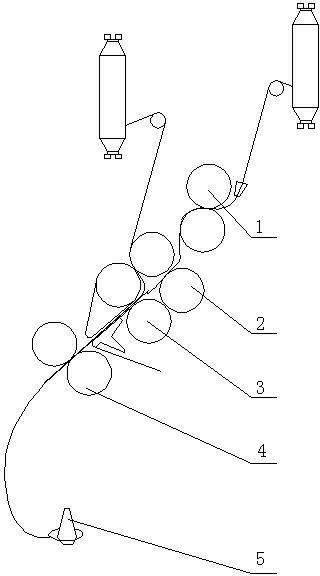

[0023] Reference attached figure 1 , the cotton roving is input through the horn, drafted through the rear roller 1, under the adjustment of the slub yarn device, the speeds of the rear roller 2, the second roller 3, and the first roller 2 are equal, and the speed of the front roller 4 remains unchanged. The slub fiber bundle is formed by drafting through the front roller 4, and the other silk is input from the second middle roller 3, and is drawn into a parallel fiber bundle after being drafted between the second middle roller 3 and the front roller 4; refer to the attached figure 2 , the parallel fiber bundles and the slub fiber bundles converge at the front jaws, and the twisting structure 5 twists the two into one yarn and then outputs it. The yarn spun in this way has the style and comfort of real silk.

Embodiment 2

[0025] Reference attached figure 1 , choose tencel or polyester roving to input through the horn, and draft through the rear roller 1, under the adjustment of the slub yarn device, the speeds of the rear roller 2, the second roller 3, and the first roller 2 are equal, and the speed of the front roller 4 is equal. Unchanged, the slub fiber bundles are formed by drafting through the front roller 4, and the other cotton is input from the second middle roller 3, and is drawn into parallel fiber bundles after being drafted between the second middle roller 3 and the front roller 4; refer to the attached figure 2 , the parallel fiber bundles and the slub fiber bundles converge at the front jaws, and the twisting structure 5 twists the two into one yarn and then outputs it. The yarn spun in this way is comfortable and durable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com