Shock-absorbing device of rolling washing machine

A technology of a drum washing machine and a shock absorption device, which is applied in the field of washing machines, can solve the problems of reducing the service life, increasing the failure coefficient of the tension spring, and the loud noise of the inner cylinder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

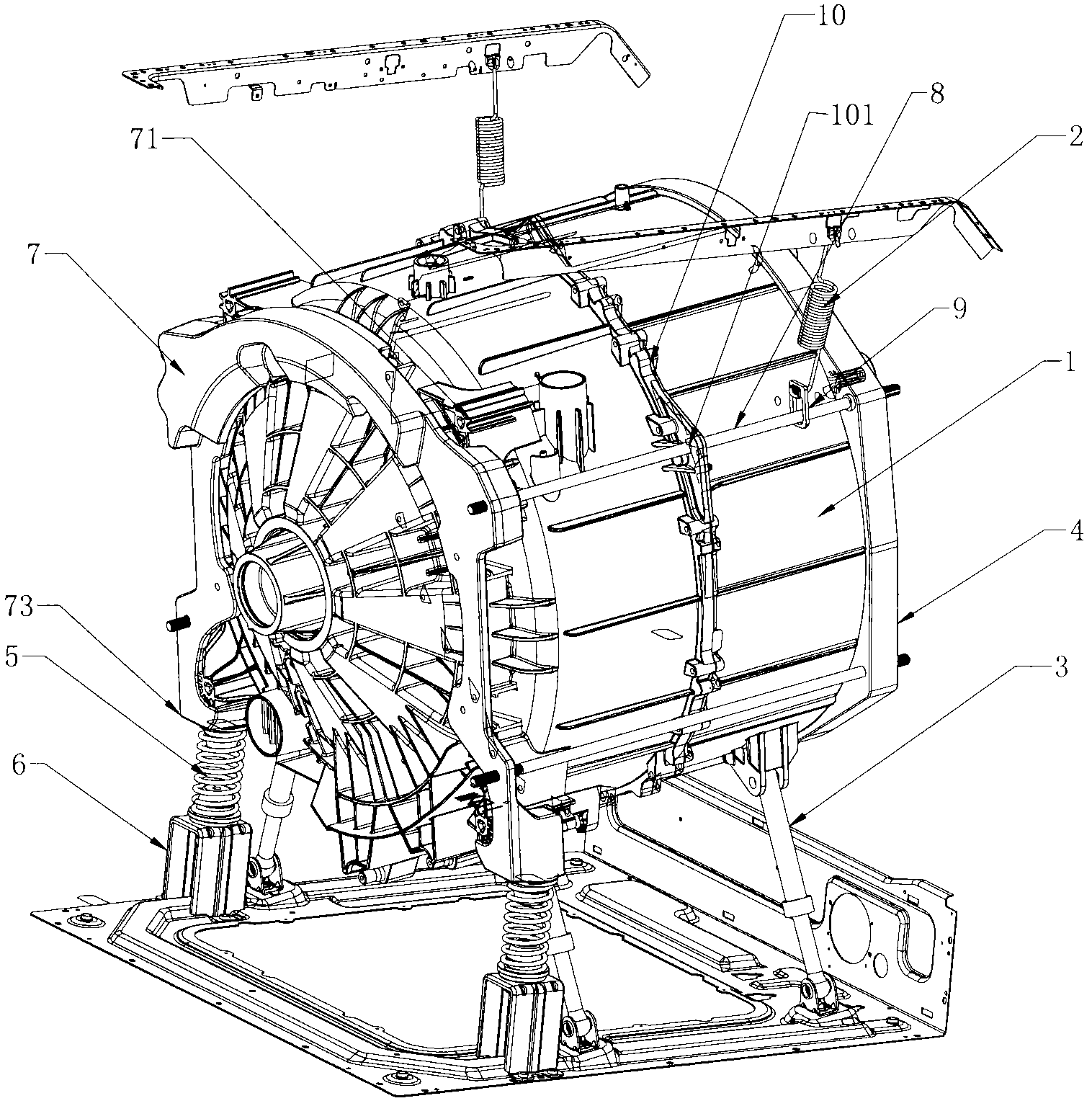

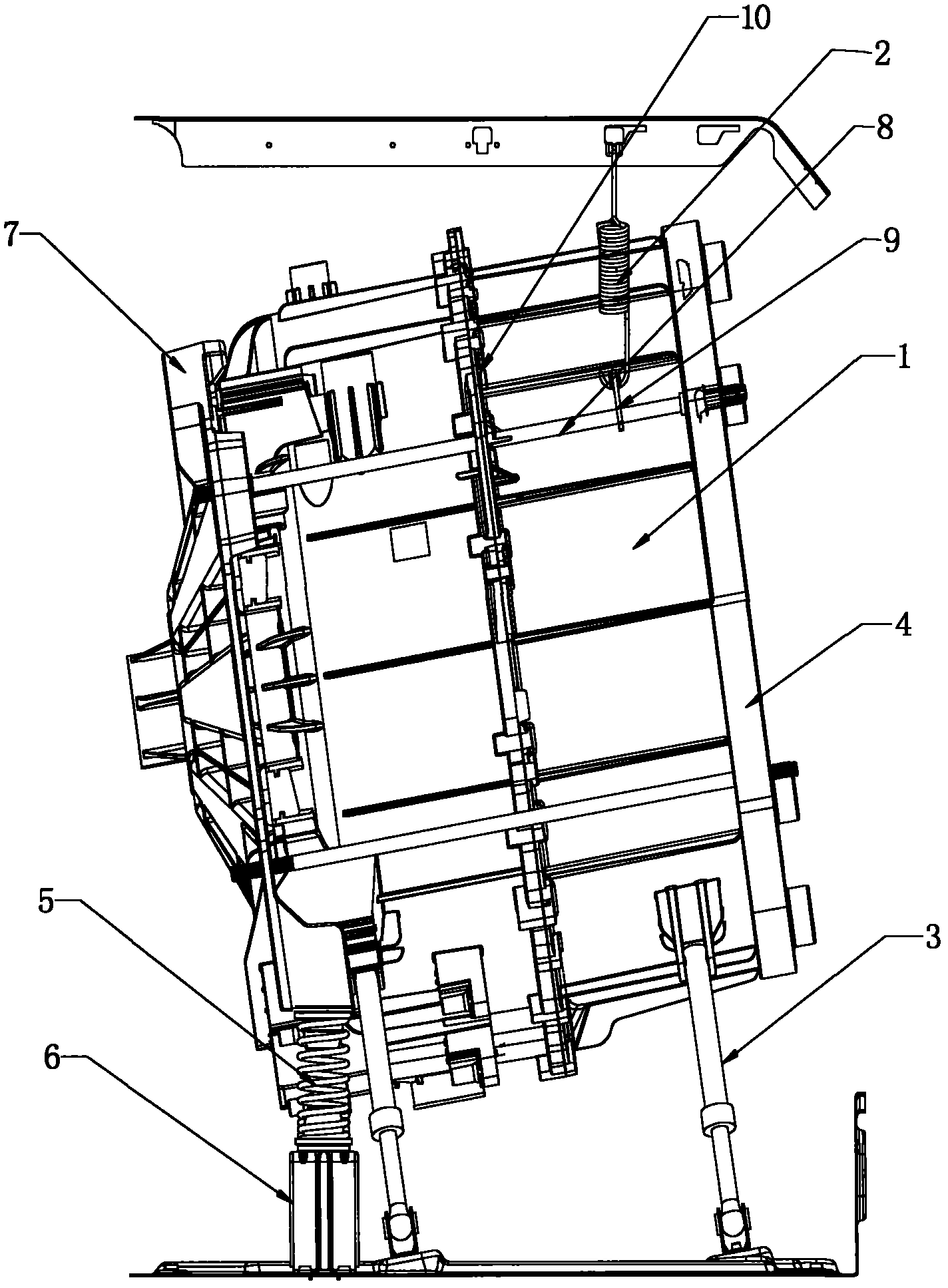

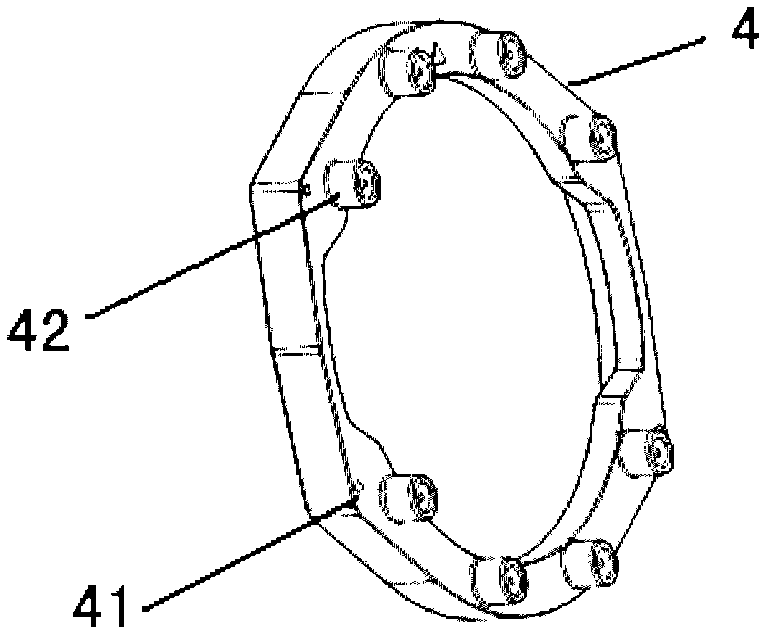

[0028] Such as figure 1 , 2, 3, the scheme is provided with a front counterweight 4 at the opening end of the outer cylinder 1, and the front counterweight adopts a ring-shaped integrated structure, and its inner diameter is consistent with the inner diameter of the opening end of the outer cylinder. Set up a snap-fit structure that is in contact with the open end of the outer cylinder to facilitate the installation and alignment of the front counterweight, and prevent the radial movement of the front counterweight after it is fixed relative to the outer cylinder. The snap-fit structure includes the front counterweight The protruding cylinder 42 on the weight is in the corresponding groove on the installation surface of the outer cylinder. When installing, insert the cylinder on the front counterweight into the groove on the open end face of the outer cylinder, and then glue the front counterweight It is fixed on the open end of the outer cylinder by connecting, bolting, ...

Embodiment 2

[0030] Such as figure 1 , 3 As shown, the rear counterweight 7 is added at the bottom of the outer cylinder of the drum washing machine. The specific size and shape of the rear counterweight need to consider factors such as the washing capacity of the drum washing machine, the self-weight of the outer cylinder, and the weight of the front counterweight. The rear counterweight includes a ring-shaped counterweight and a U-shaped counterweight. This plan adopts a U-shaped counterweight, which is installed on the outer bottom of the outer cylinder by means of snap-fitting, bolts, and bonding, and is set on the edge of the rear counterweight. There is a fixed block 71 for engaging or clamping the bottom of the outer cylinder. Similarly, the rear counterweight can also adopt the same engaging structure as the front counterweight, that is, the rear counterweight is fixed after being inserted into the bottom of the outer cylinder in a manner corresponding to the convex groove. After...

Embodiment 3

[0032] Such as figure 1 , 2 As shown, on the basis of the foregoing embodiments, a front counterweight 4 and a rear counterweight 7 are respectively installed at the front and rear ends of the outer cylinder of the drum washing machine at the same time. This installation method can adjust the distribution of the center of gravity of the outer cylinder, which is beneficial to each The shock absorption of the damping support rod 3 and the extension spring 2 can prevent the damping support rod and the extension spring at a certain end or somewhere from being subjected to a large centrifugal force for a long time, thereby causing premature damage. Such as Image 6 As shown, the front counterweight 4 and the rear counterweight 7 are fixed together by metal tie rods 8, as image 3 , 4 As shown, the front counterweight 4 and the rear counterweight 5 are provided with fixed tables 41 and 71 protruding from the diameter of the outer cylinder, and the fixed tables are provided with i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com