Water wheel comprising a built-in generator

A technology of generator and water wheel, applied in the field of water wheel, can solve the problems of wear, high maintenance, heavy cost and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

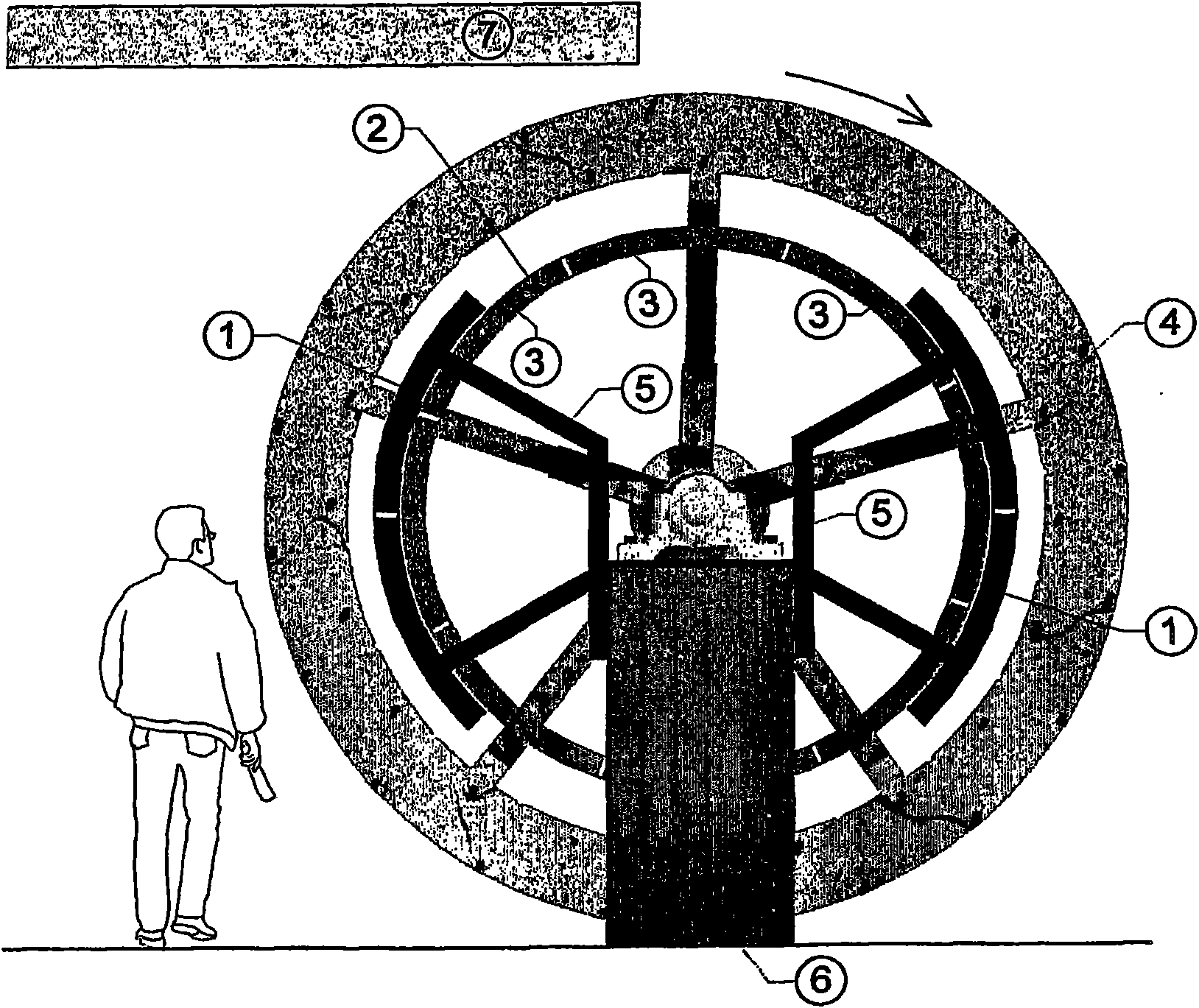

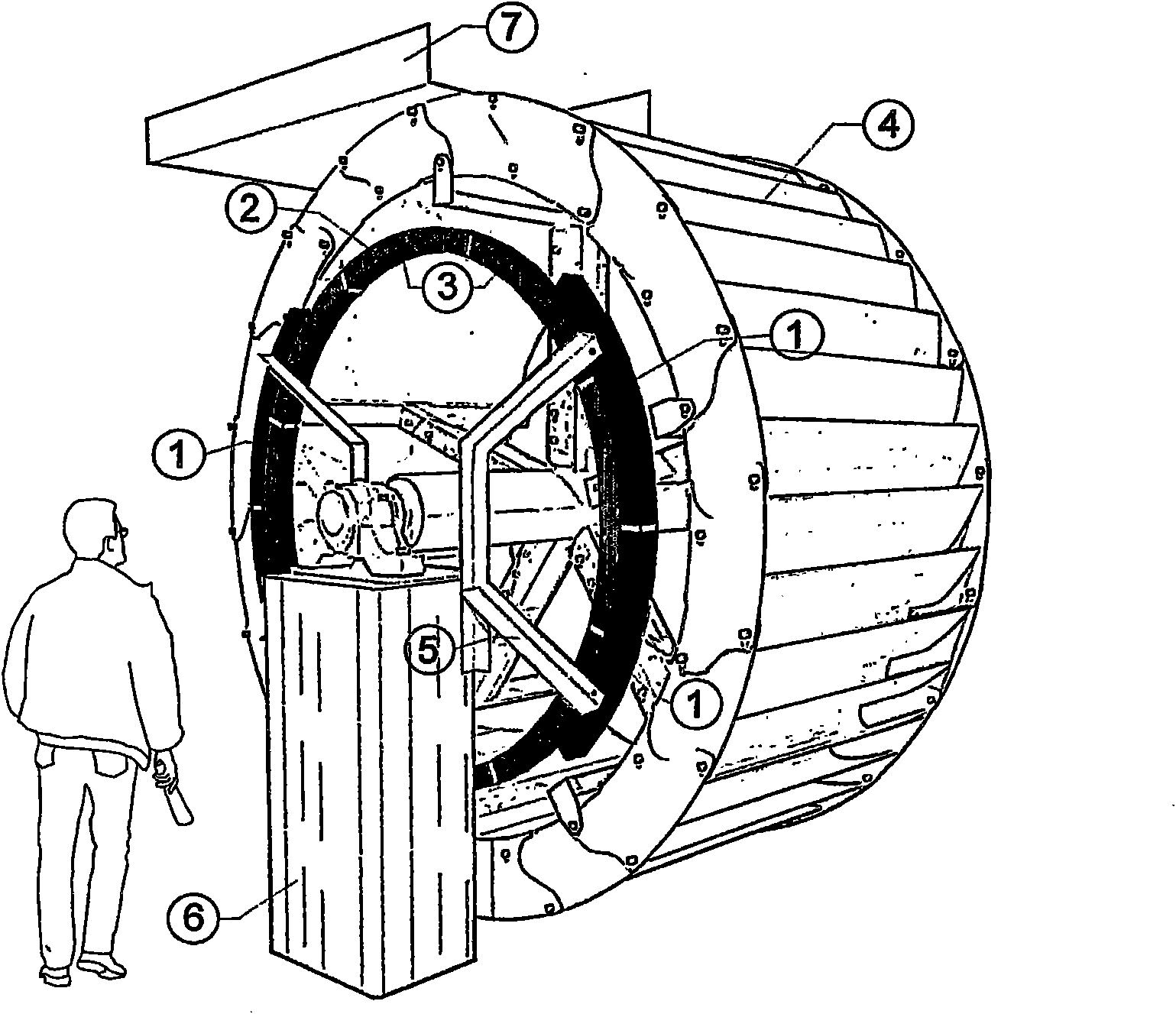

[0024] In the embodiment, water wheel 4 is provided, and they follow figure 2 , 3 and 8 are designed as an upper impact wheel 4 with a correspondingly assigned water supply channel 7 and are mounted in a known manner via a stationary base 6 . Water wheel 4 is here formed in this case from individual rim elements.

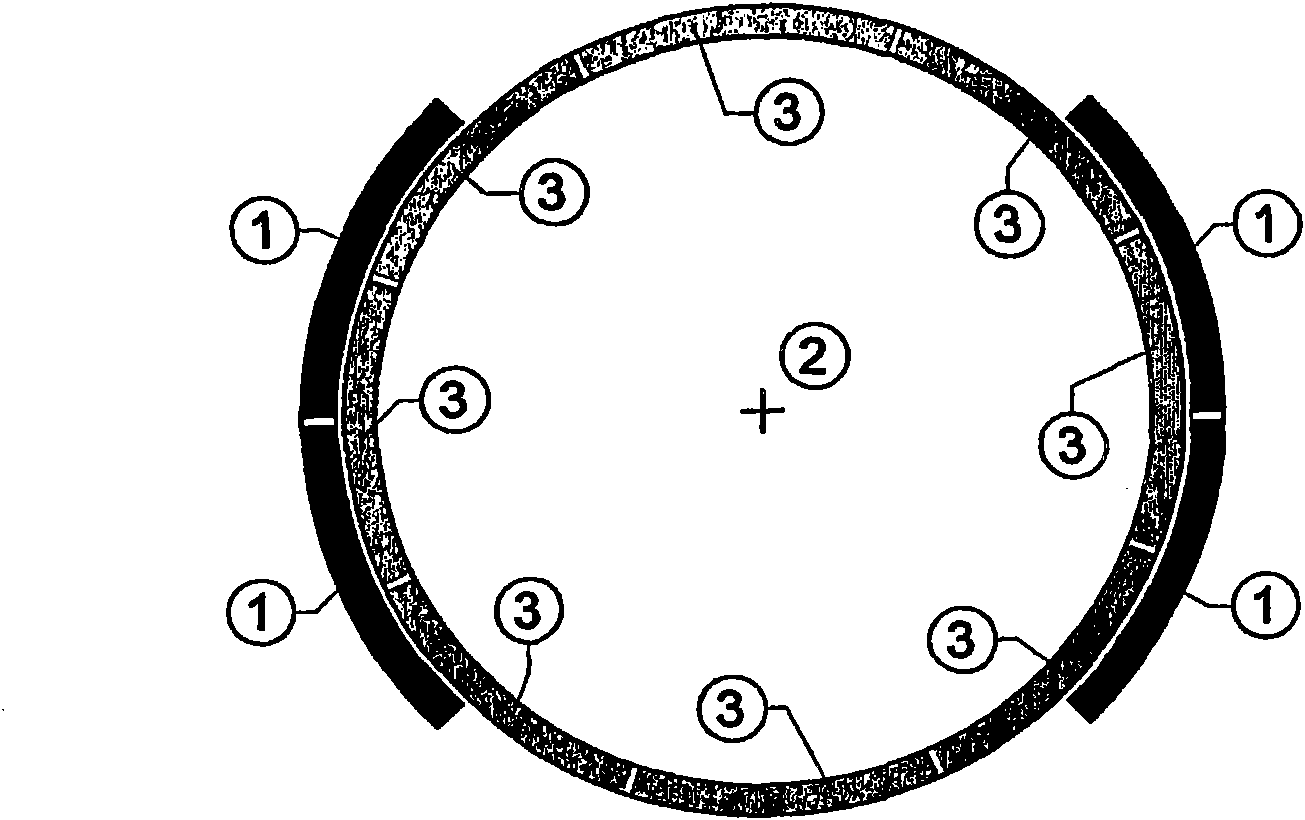

[0025] A ring generator is coupled to the water wheel 4 , which ring generator is formed by the rotor 2 as ring element and is fixedly connected to the water wheel 4 . Here it is connected to the spokes of the water wheel body or rests directly on the formed ring.

[0026] This annular element is composed in a modular manner as a rotor 2 of individual segments 3 equipped with corresponding permanent magnets 8 . High-power magnets are used here, such as those known under the trade name NEODYN magnets. These permanent magnets 8 are arranged in the exemplary embodiment on the front side, rear side, inner surface or outer surface of the ring element as the rotor 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com