Wheelwork noise control method and controller

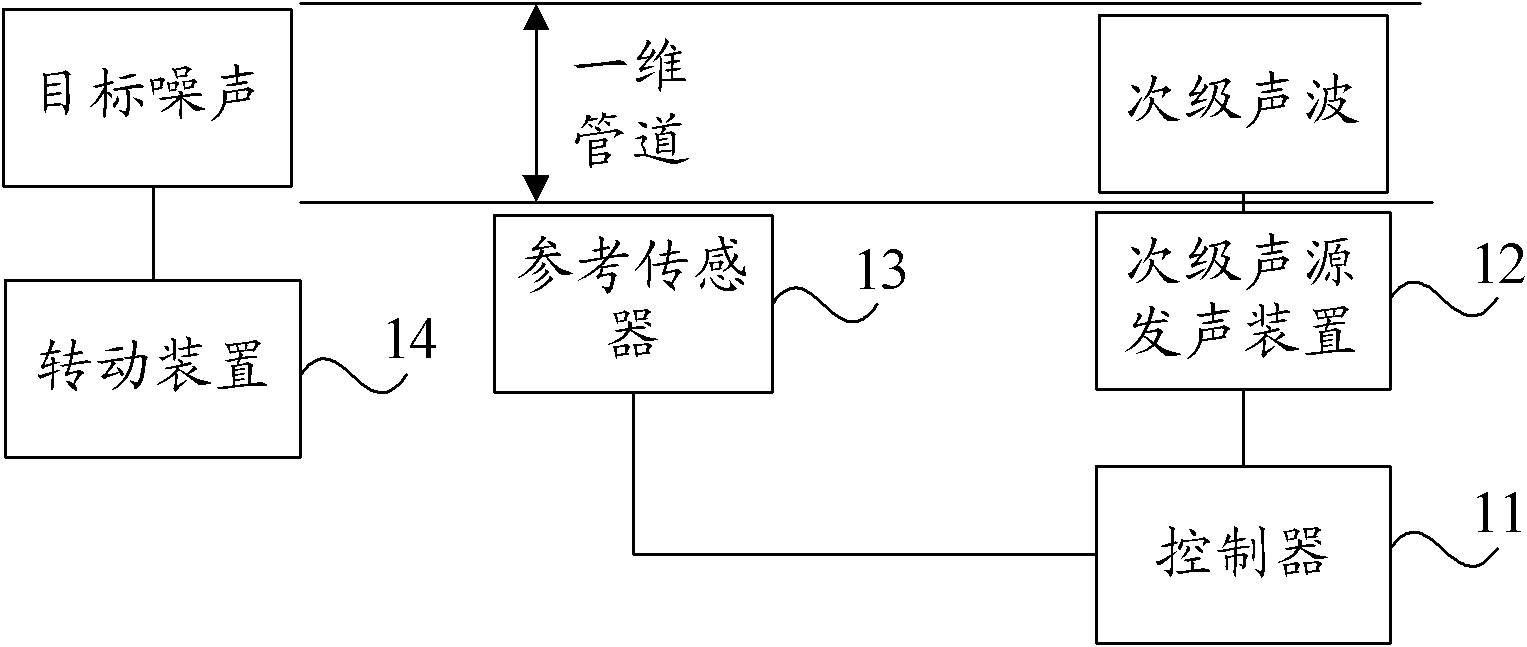

A technology of rotating device and noise control, applied in the direction of active noise control, sounding equipment, instruments, etc., can solve the problems of large noise change and inability to achieve noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

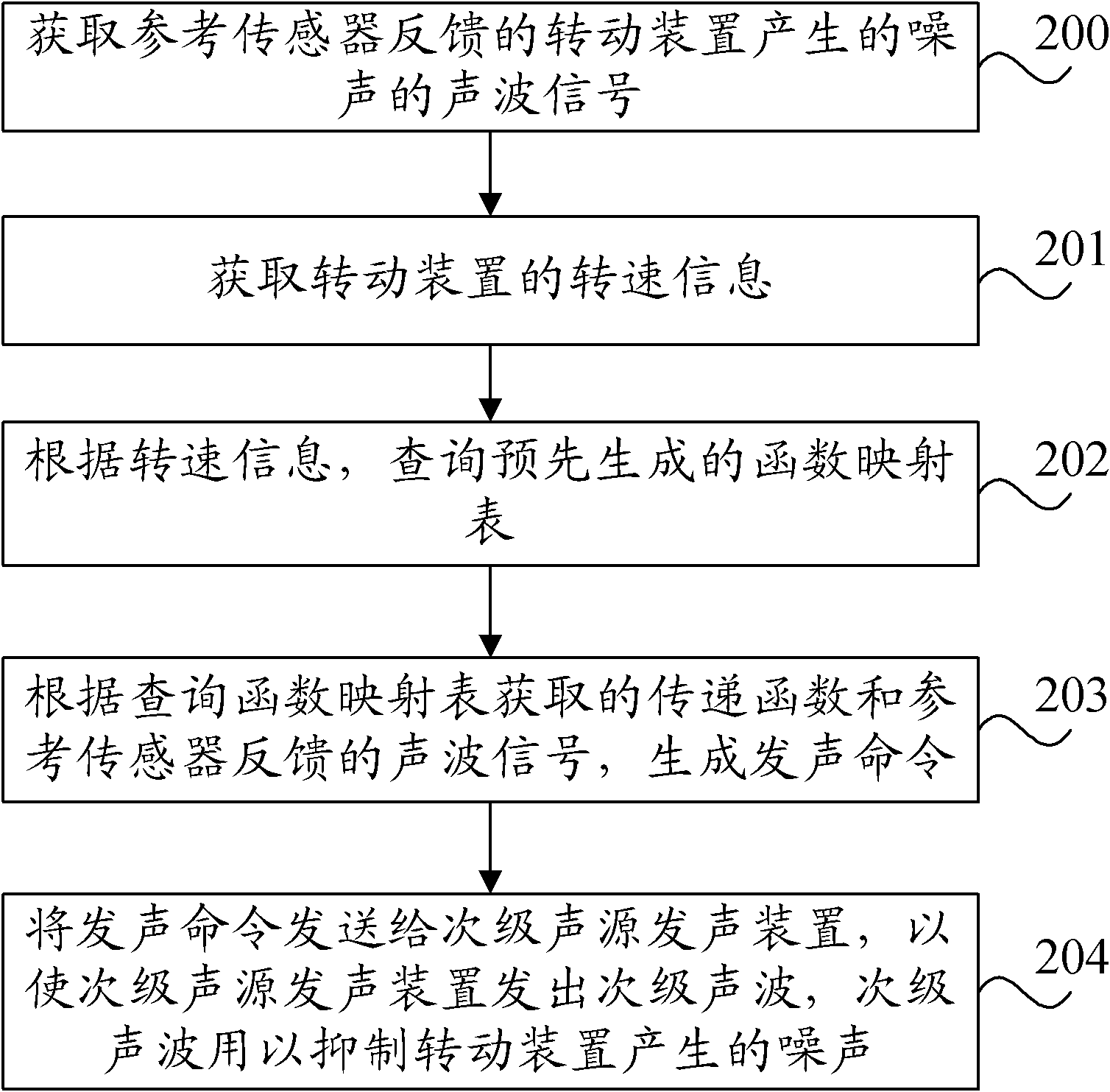

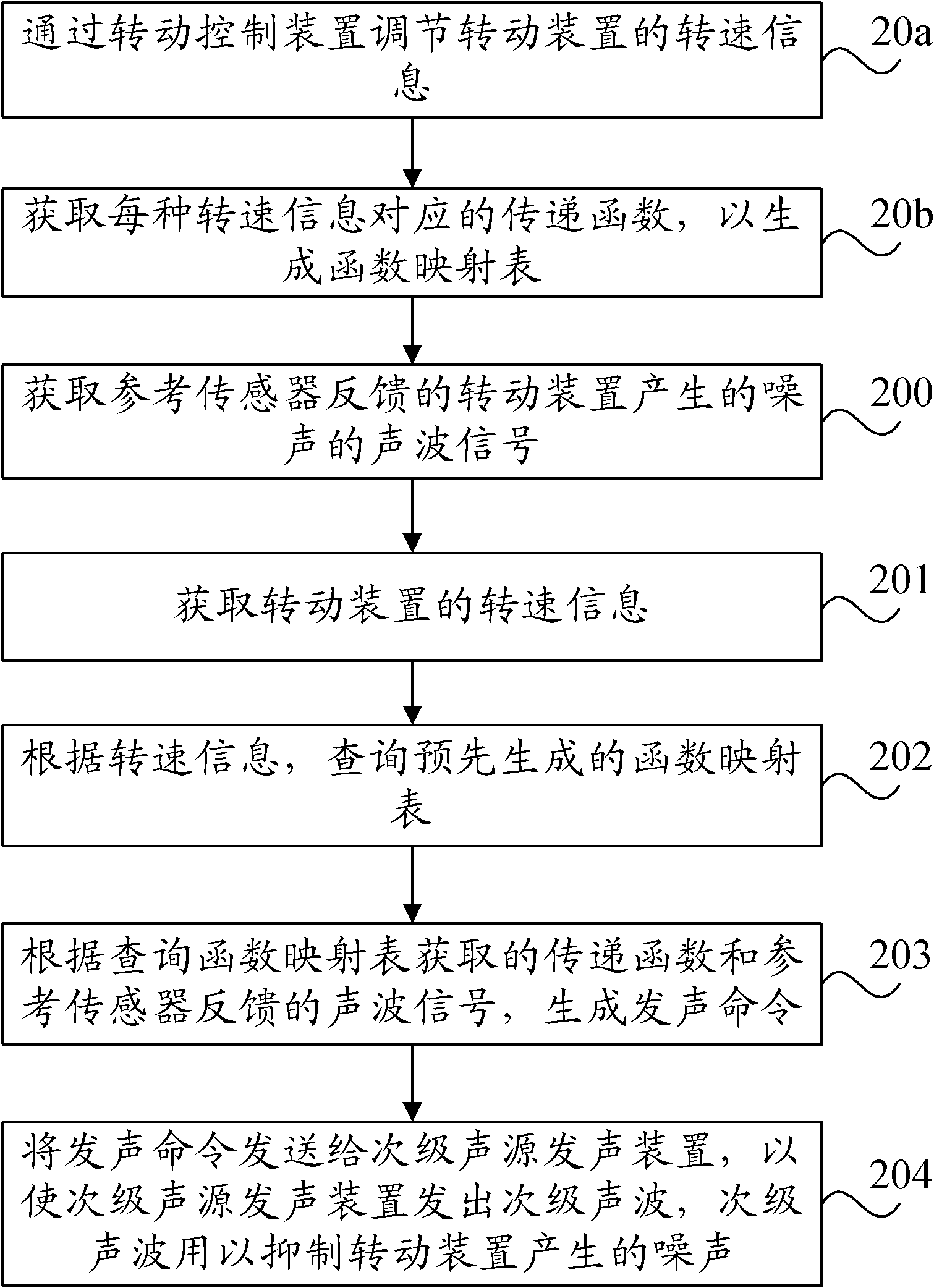

Method used

Image

Examples

specific Embodiment approach

[0058] Based on the above, this embodiment provides a specific implementation of step 203: when the rotating device 14 generates target noise, and the controller 11 sends a sound command to the secondary sound source sound generating device 12, the secondary sound source generating device 12 sends out a secondary sound source Under the environment of sound waves, the sound wave signal (comprising target noise, secondary sound wave and background noise) that reference sensor 13 detects; Controller 11 first calculates the position of reference sensor 13 according to the transfer function C and the last sound command. Secondary sound wave, then the acoustic wave signal fed back by the reference sensor 13 is subtracted from the calculated secondary sound wave to obtain the target noise; then by applying the transfer function A and the obtained target noise, the target noise is propagated to the assumption that there is an error The target sound wave signal at the sensor position (i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com