Multifunctional grass trimmer

A grass trimmer and multi-functional technology, applied in the field of grass trimmers, can solve the problems of lack of multi-functional adjustment means and troublesome operation, and achieve the effect of powerful adjustment function and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The embodiments of the present invention will be described in detail below according to the above-mentioned drawings.

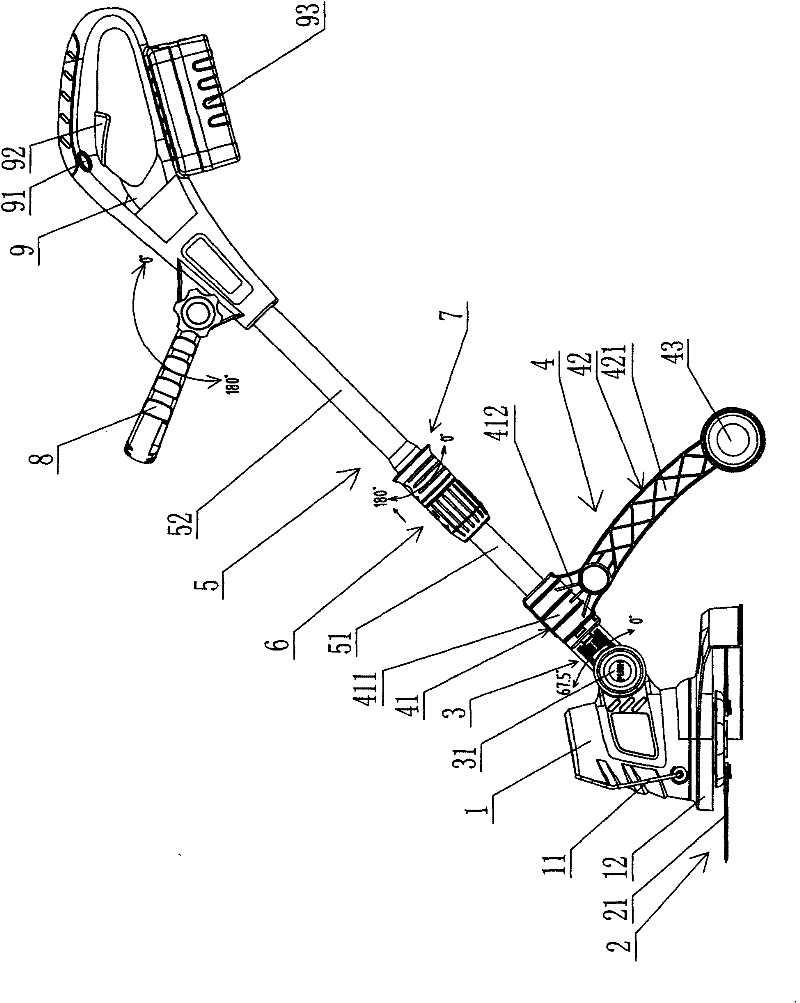

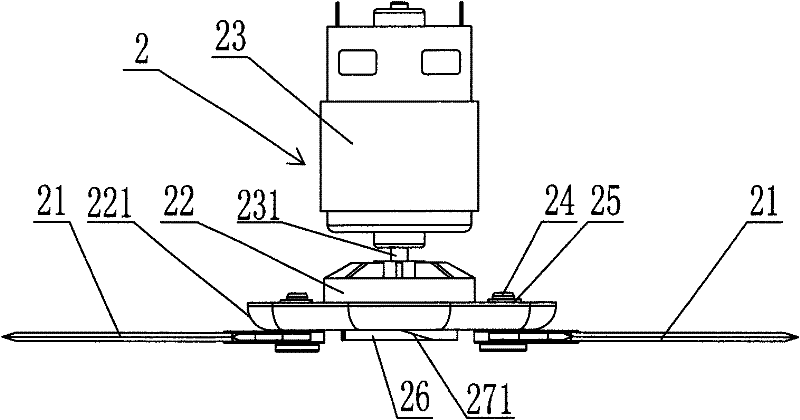

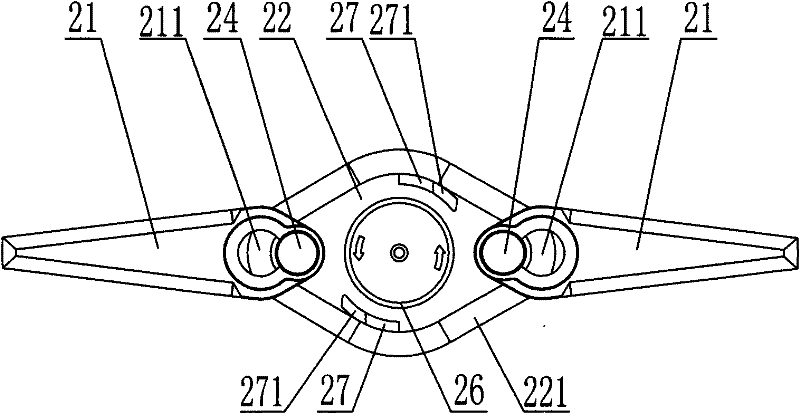

[0061] Such as Figure 1 ~ Figure 4 As shown in 1, 1. Grass cutting head, 11. Protective steel wire, 12. Protective cover, 13. One-piece cap, 14. Spring, 15. Rear connector, 16. Rear connection hole, 17. Positioning groove, 18. Limit Bit table, 2. Cutting knife group, 21. Blade, 211. Large mounting hole, 212. Small mounting hole, 22. Knife rest, 221. Fillet, 23. Motor, 231. Motor shaft, 24. Connecting pin, 241 .Big end, 242. Small end, 243. Insert groove, 25. Open collar, 26. Retaining ring, 27. Retaining rib, 271. Chamfer, 28. Connecting sleeve, 3. Connecting rod, 31. Locking button, 311. Raised strip, 32. Front connector, 33. Connecting column, 331. Elastic button, 332. Barb, 333. Narrow groove, 334. Wide groove, 34. Front connecting hole, 4. Roller assembly, 41 .fixed frame, 411. connecting pipe, 412. connecting seat, 413 keyhole, 414. narrow rib,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com