Ground processing system

A processing system and ground technology, applied in manual sweeping machines, suction filters, cleaning equipment, etc., can solve the problem of not being able to be removed from the charging stand, and achieve the effect of beautifying the living environment and effective living environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

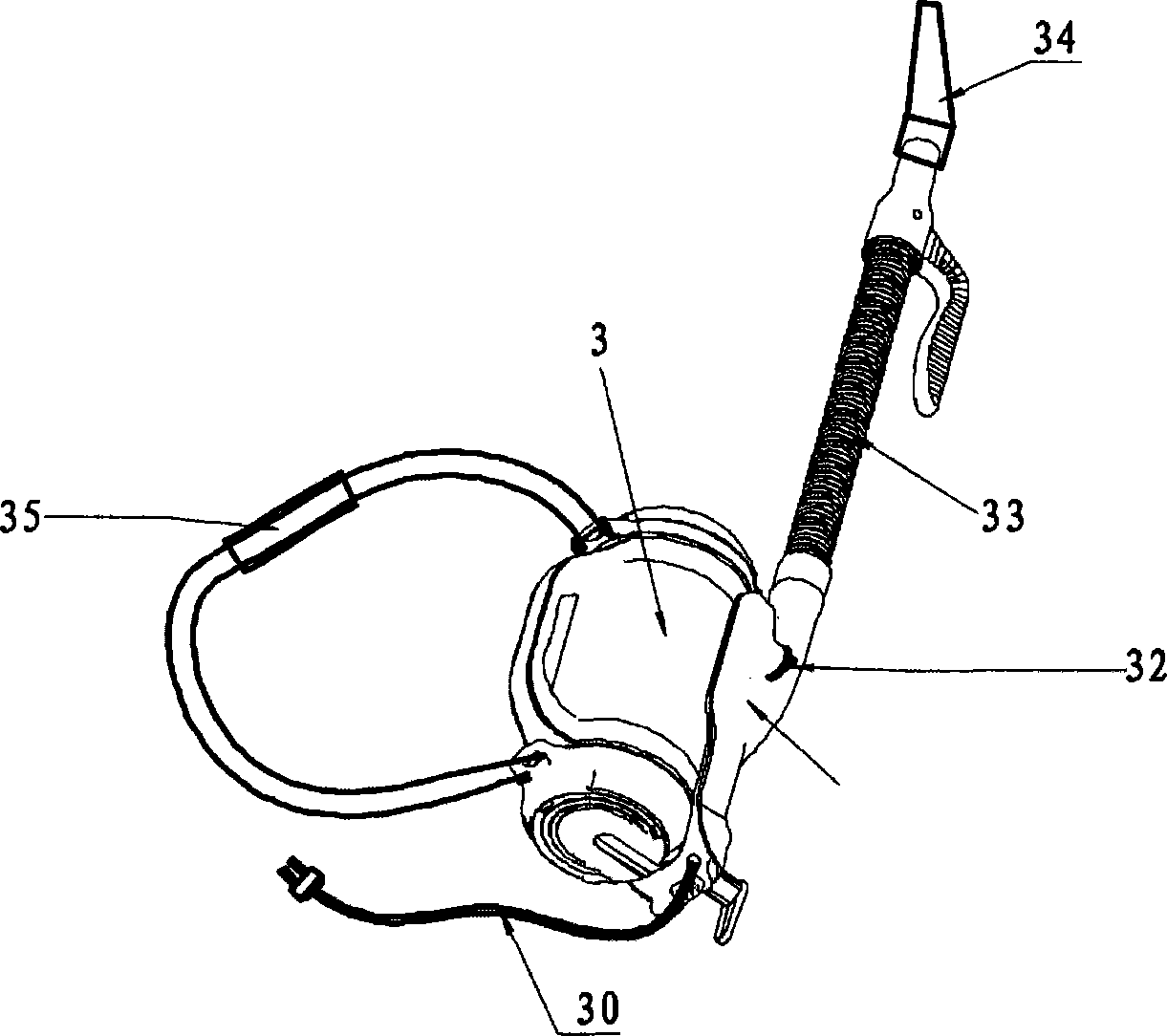

[0053] In the technical solution of this embodiment, the rotation of the transmission wheel is used to drive the pulley bracket and the locking piece, so that the locking piece is separated from the matching piece of the locking piece, so as to achieve the purpose of detaching the dust collection unit from the base.

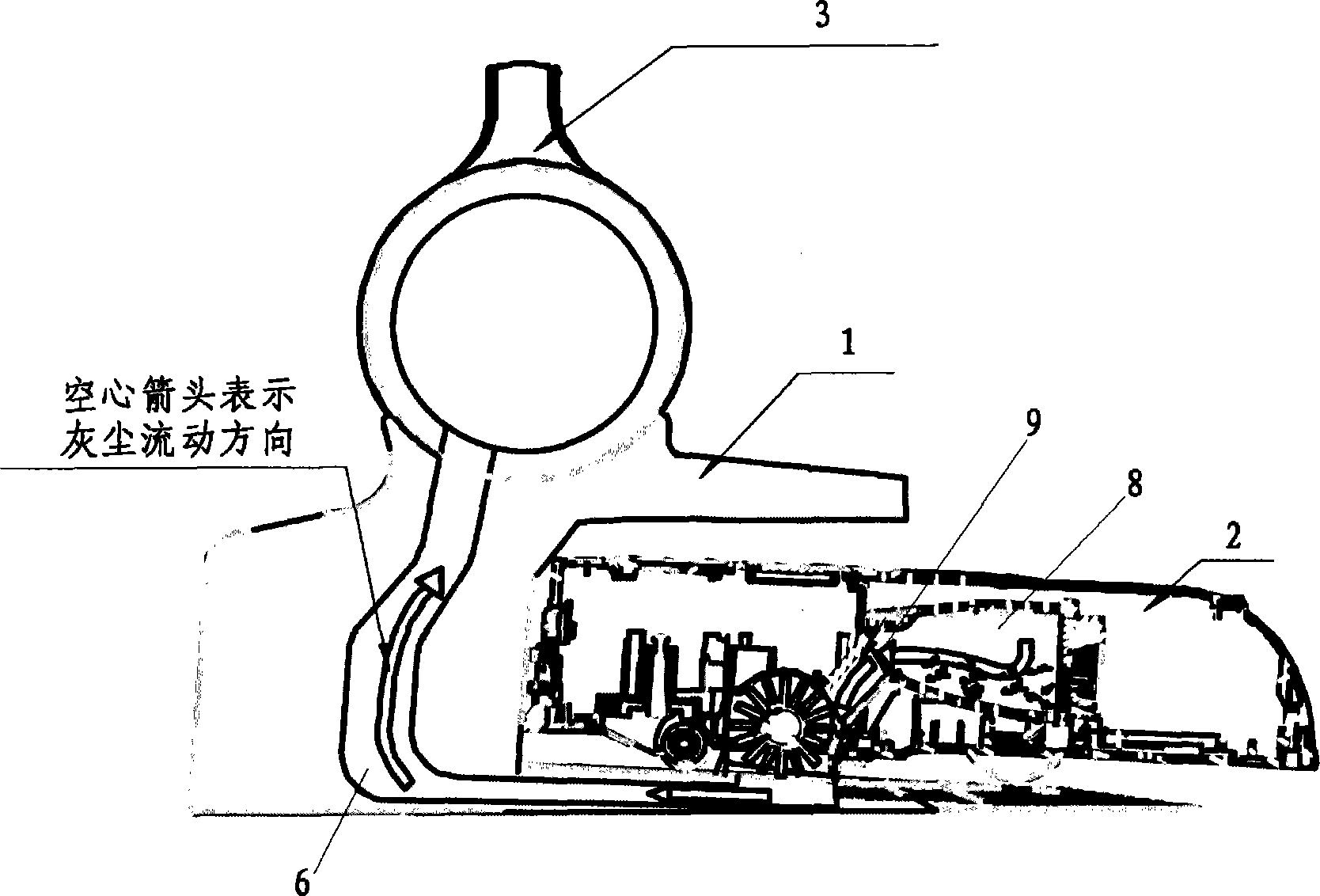

[0054] Combine below Figure 4~5 The process of detaching the dust collection unit from the base body of the base will be described.

[0055] The release part 22 is affected by an external force and pulls the traction member 410. The transmission wheel bracket 403 is subjected to the traction force to pull the first transmission wheel 401 to rotate. The first transmission wheel 401 and the second transmission wheel 411 mesh with each other. Under the action of the first transmission wheel 401, The second transmission wheel 411 rotates thereupon, the first pulley bracket 406 is connected with the first transmission wheel 401 and the first locking member 404 respec...

Embodiment 2

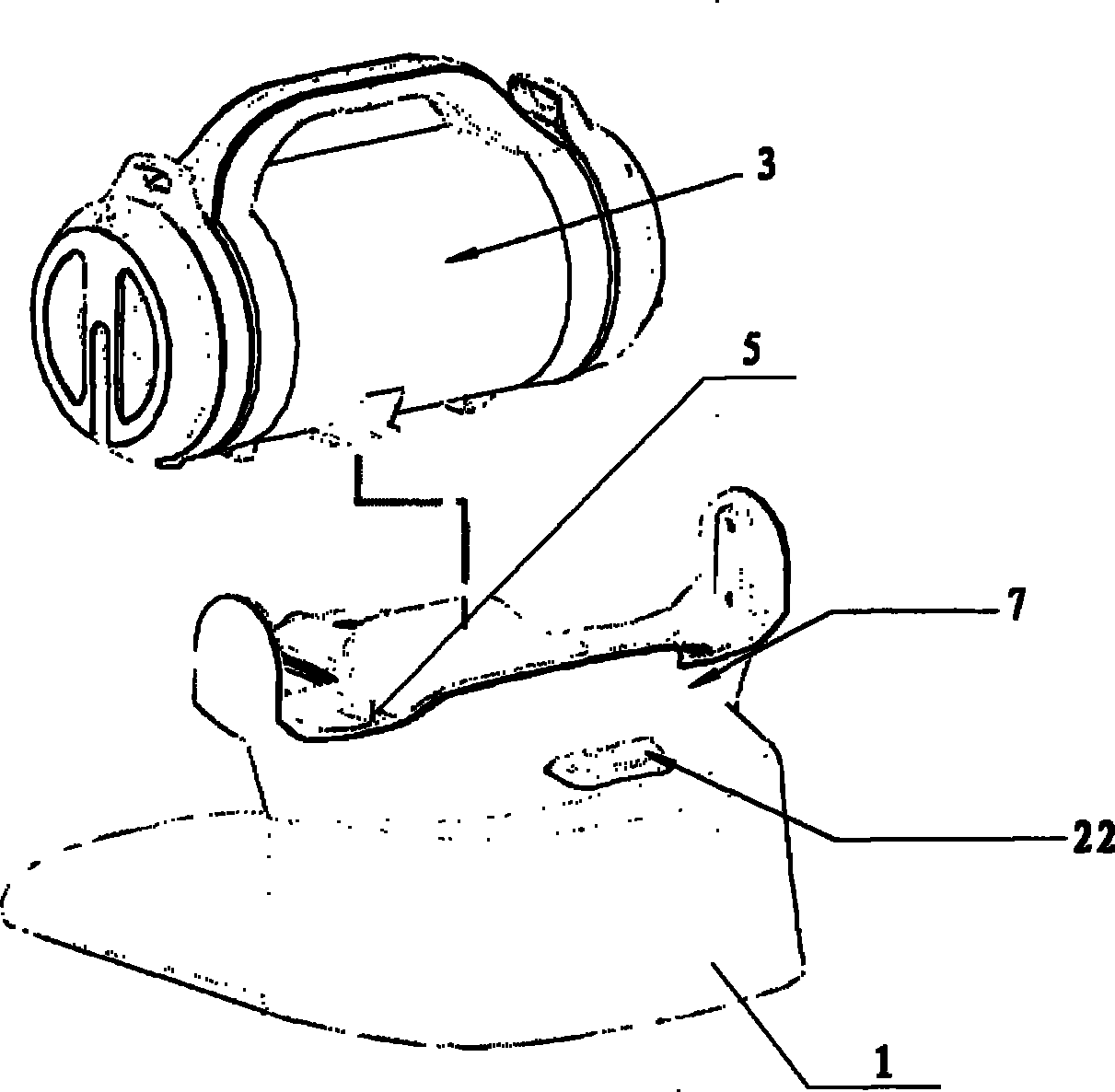

[0060] In the technical solution of this embodiment, the rotation of the locking member bracket 203 is used to drive the first locking member 202 and the second locking member 212 to produce relative motion, so that the first and second locking members are respectively connected to the first and second locking members. The matching parts of the fastening parts are separated to achieve the purpose of detaching the dust collection unit 3 from the base body 7 .

[0061] Combine below Figure 7 The process of detaching the dust collection unit from the base body of the base will be described.

[0062] The release part 22 is acted by an external force to drive the first locking part 202 to move, so that the locking part bracket 203 rotates around the rotating shaft 210, and the second locking part 212 connected with the locking part bracket 203 moves accordingly, thereby respectively driving the first locking part 202 The first locking part 202 and the second locking part 212 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com