Coating device

A coating device and export technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of rough coating surface and long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

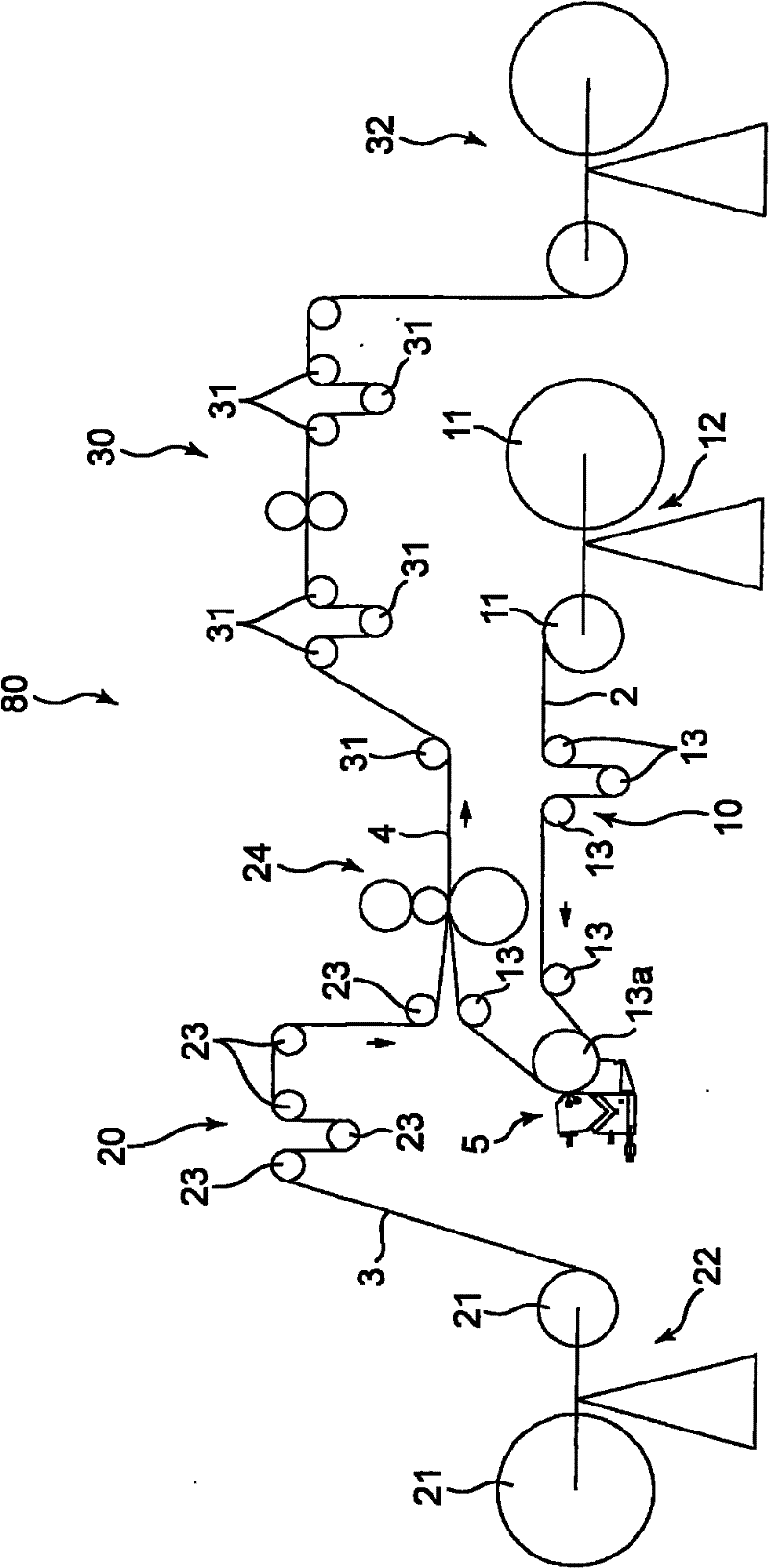

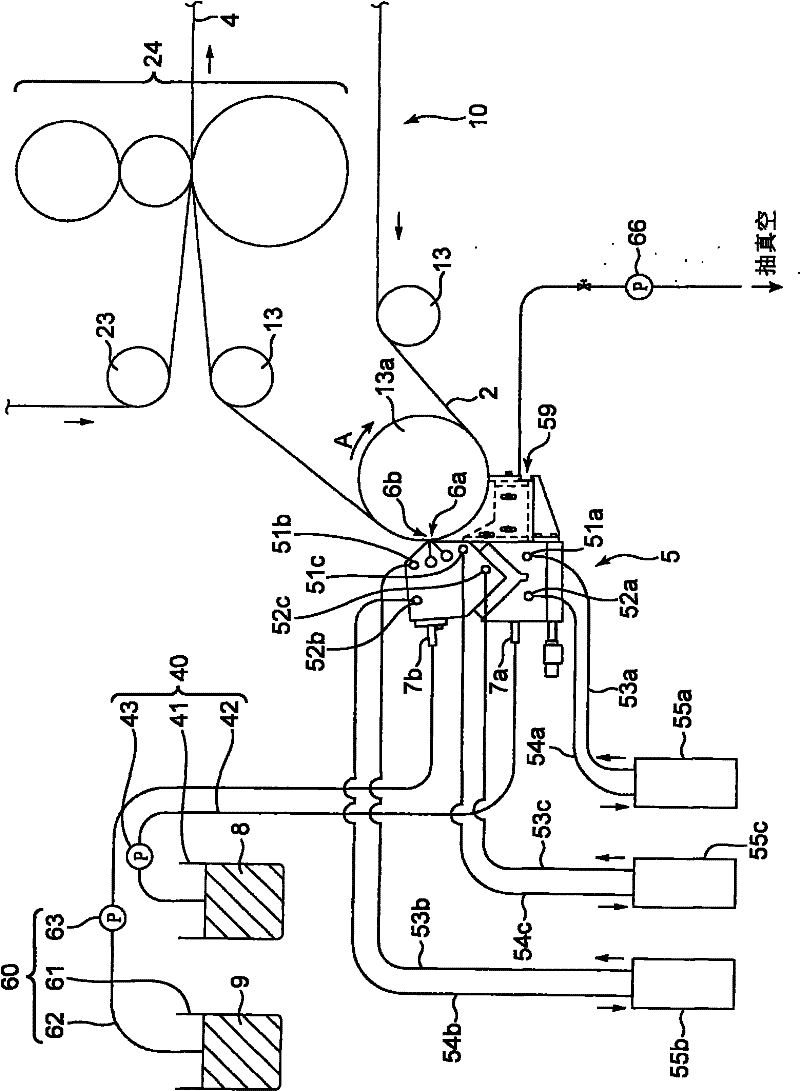

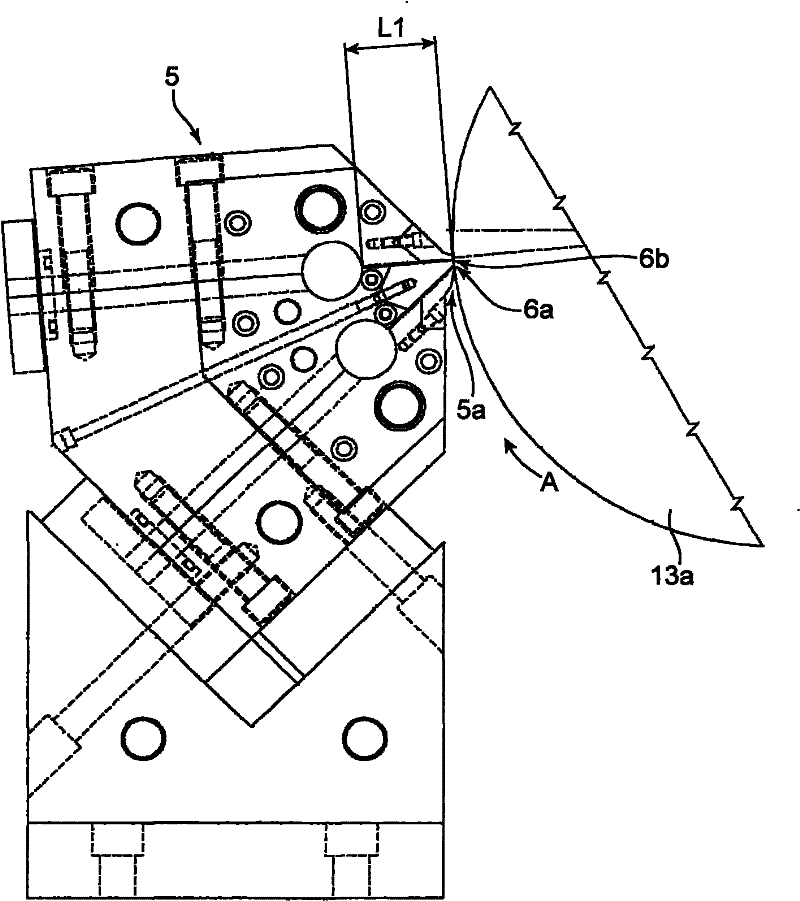

[0032] Next, embodiments of the present invention will be specifically described. figure 1 is a schematic view showing a laminator having a coating device according to the first embodiment of the present invention, figure 2 is a schematic diagram of a coating device provided in the laminator.

[0033] This laminator 80 is a device for producing a laminated product by bonding sheet-shaped feed materials (web) as base materials to each other using a two-component curing type solventless adhesive. Specifically, the laminator 80 includes: a first conveying line 10 for conveying the first feed material 2 , a second conveying line 20 for conveying the second feed material 3 , and a second conveying line 20 for conveying the first feed material 3 . A third conveying line 30 of a laminated product 4 formed by bonding the feed material 2 and the second feed material 3 conveyed in the second conveying line 20 by an adhesive is arranged facing the first conveying line 10 and A die co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com