Drawing machine for internal-threaded pipe

A technology of internal threaded pipe and drawing machine, which is applied in the direction of heat exchange equipment, etc., achieves the effects of low cost, simple structure, and easy transportation and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

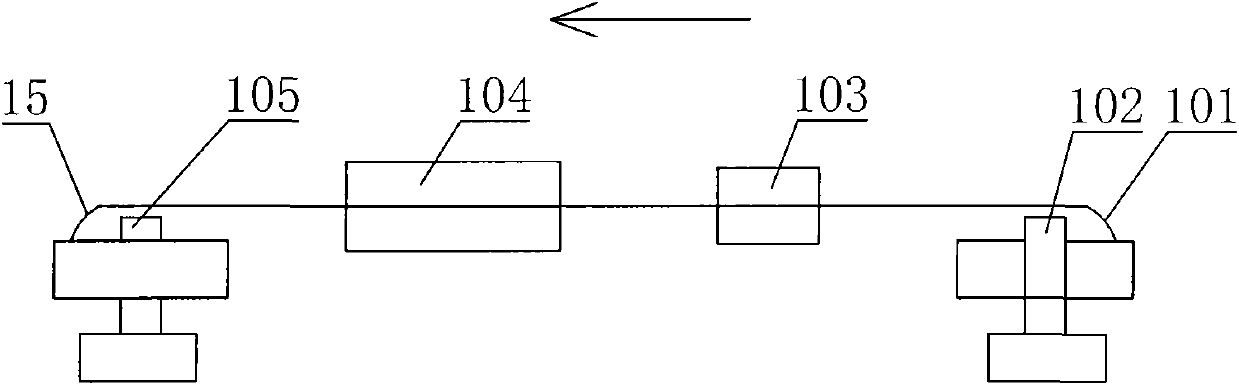

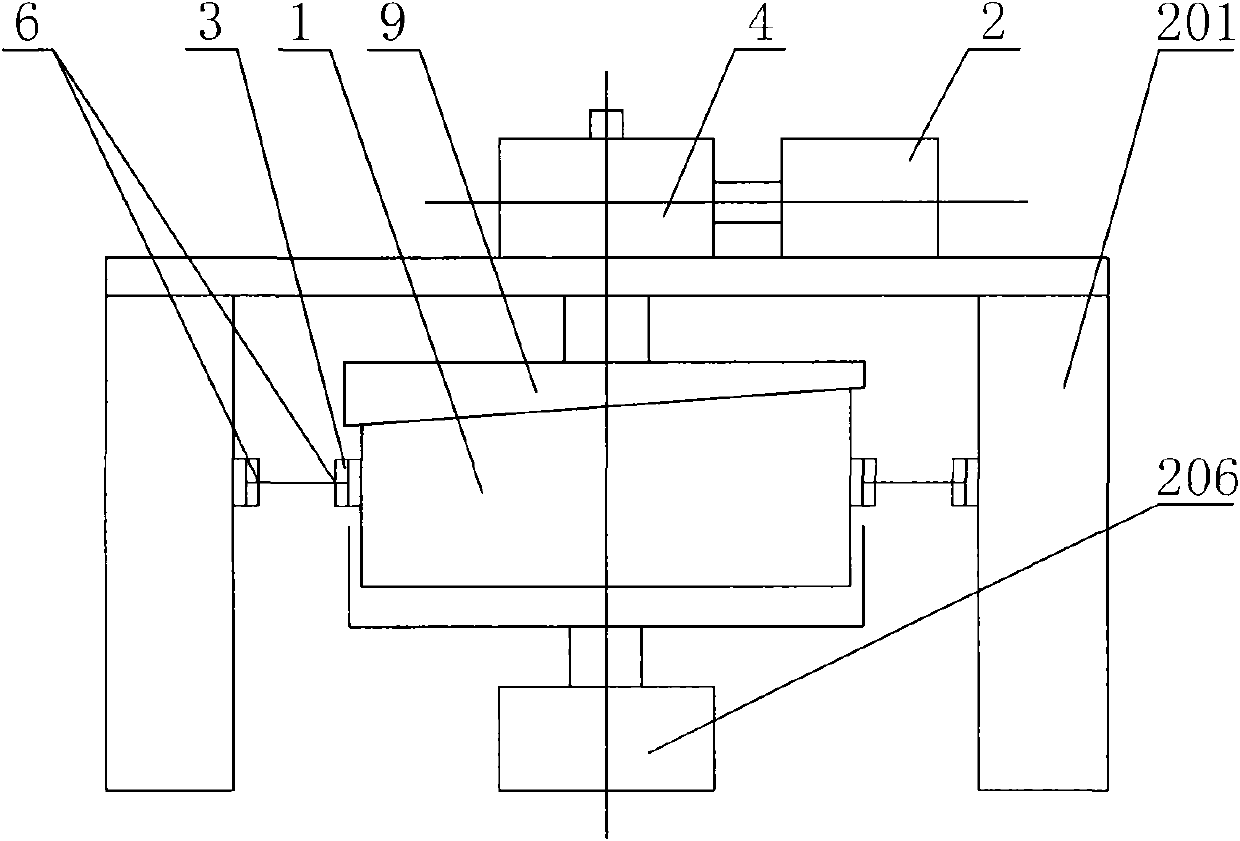

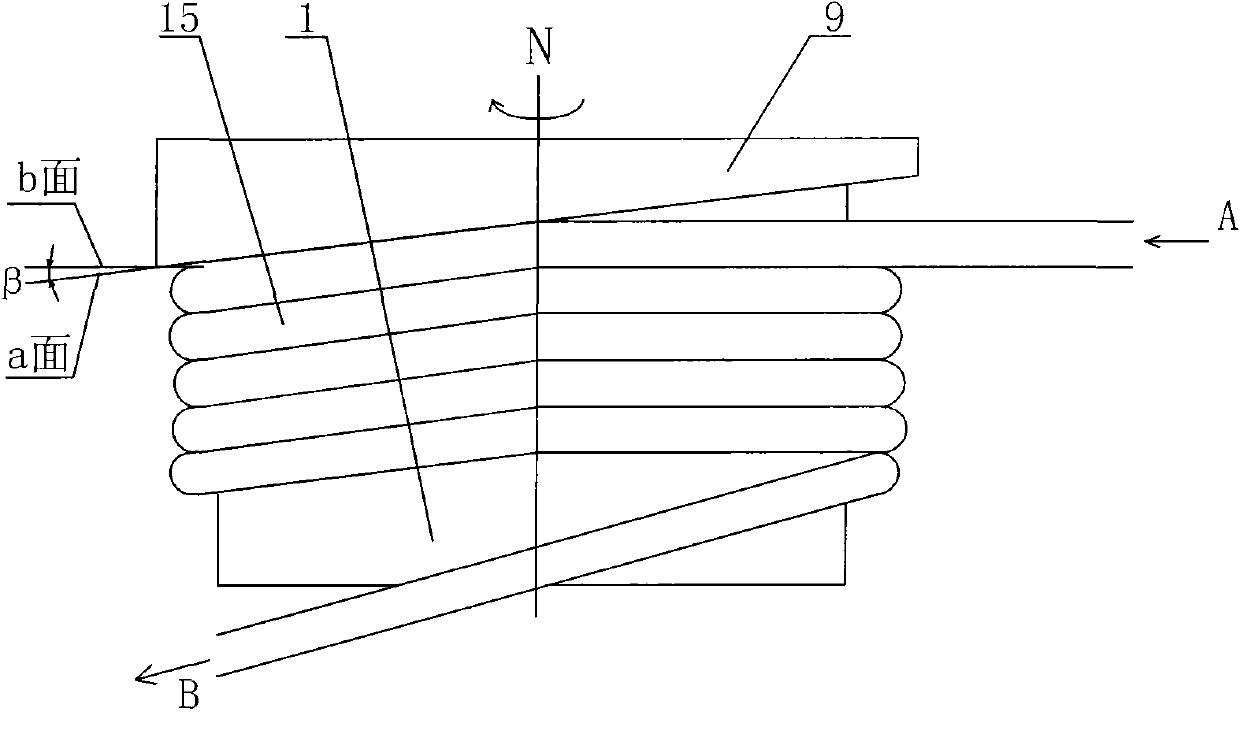

[0033] Such as Figure 8 and Figure 9 As shown, a method for drawing an internally threaded pipe, the internally threaded pipe 15 is wound several times on the outer surface of the drawing cylinder 1, the C end of the internally threaded pipe is at the bottom, and the D end of the internally threaded pipe is at the top. The pressure roller 6 is pressed against the outer diameter of the internally threaded pipe 15, so that the internally threaded pipe 15 is close to the drawing cylinder 1. During the drawing process, the power device 2 drives the drawing cylinder 1 and the discharge cylinder 1 through the transmission device 4. The ring 9 rotates, and the discharge ring 9 is continuously discharged upward on the drawing cylinder 1 .

[0034] Such as Figure 8 to Figure 12 As shown, an internally threaded pipe drawing machine for realizing the above-mentioned internally threaded pipe drawing method includes a drawing cylinder 1, a power device 2, a pressure roller device 3, a...

Embodiment 2

[0043] The drawing method of this embodiment is the same as that of the first embodiment.

[0044] This embodiment is basically the same as the internally threaded pipe drawing machine in Embodiment 1, except that the radial gap δ in this embodiment is 0.8 mm, and the included angle α is 0.1°.

Embodiment 3

[0046] The drawing method of this embodiment is the same as that of the first embodiment.

[0047] This embodiment is basically the same as the internally threaded pipe drawing machine in Embodiment 1, except that the radial gap δ in this embodiment is 1.2mm, and the included angle α is 1.5°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com