Production technology of aluminum alloy circular pipe for producing photosensitive drum of fine definition laser printer

A laser printer and high-definition technology, which is applied to the production process of aluminum alloy round tubes for photosensitive drums of high-definition laser printers, can solve the problem that the surface of the tube is prone to coarse grains, the photosensitive drum has high reflectivity, and affects photoelectric conversion. problems, to achieve the effects of easy grain size control, low reflectivity, and uniform chemical composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further describe the present invention, the production process of the aluminum alloy round tube for the photosensitive drum of the high-definition laser printer of the present invention will be further described below in conjunction with the examples.

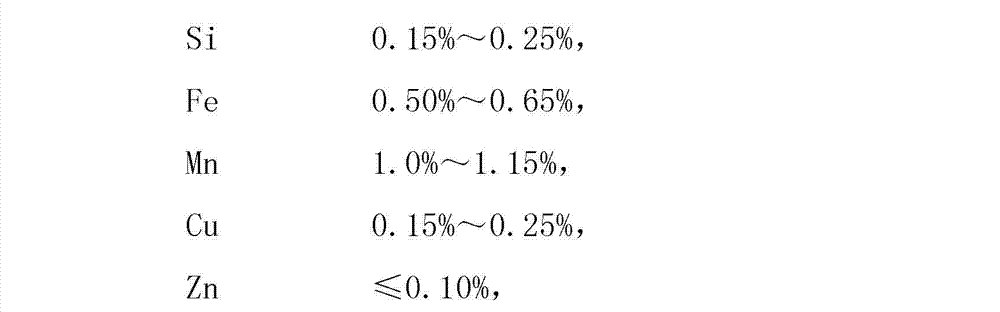

[0038] Table 1 shows the alloy element content of the aluminum alloy material used in the production process of the aluminum alloy round tube for the photosensitive drum of the high-definition laser printer of the present invention.

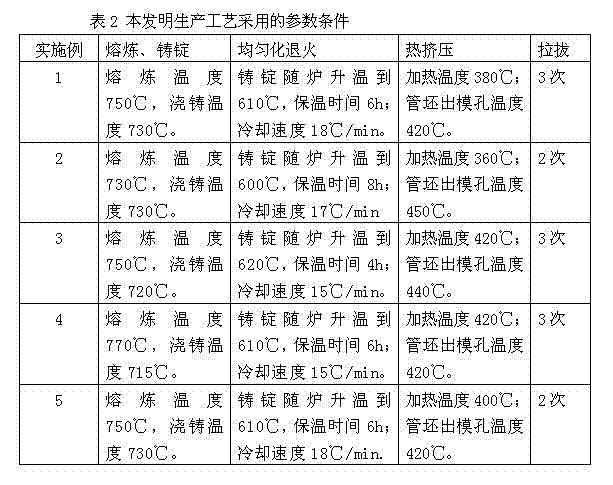

[0039] Table 2 shows the parameter conditions of the production process of the aluminum alloy round tube for the photosensitive drum of the high-definition laser printer of the present invention.

[0040] The processing technology and the equipment adopted are the same as those in the summary of the invention.

[0041] Table 1 Alloy element content of the aluminum alloy material used in the production process of the present invention (mass percentage, %)

[0042] Examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com