Automatic winding shaping mill of multilayer composite rubber tube

A technology of composite rubber hose and forming machine, which is applied in the direction of tubular articles, other household appliances, household appliances, etc., can solve the problems of high working intensity, poor consistency of winding density and tightness, and difficult to control winding tension, so as to reduce the working intensity. , maintain consistency, improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

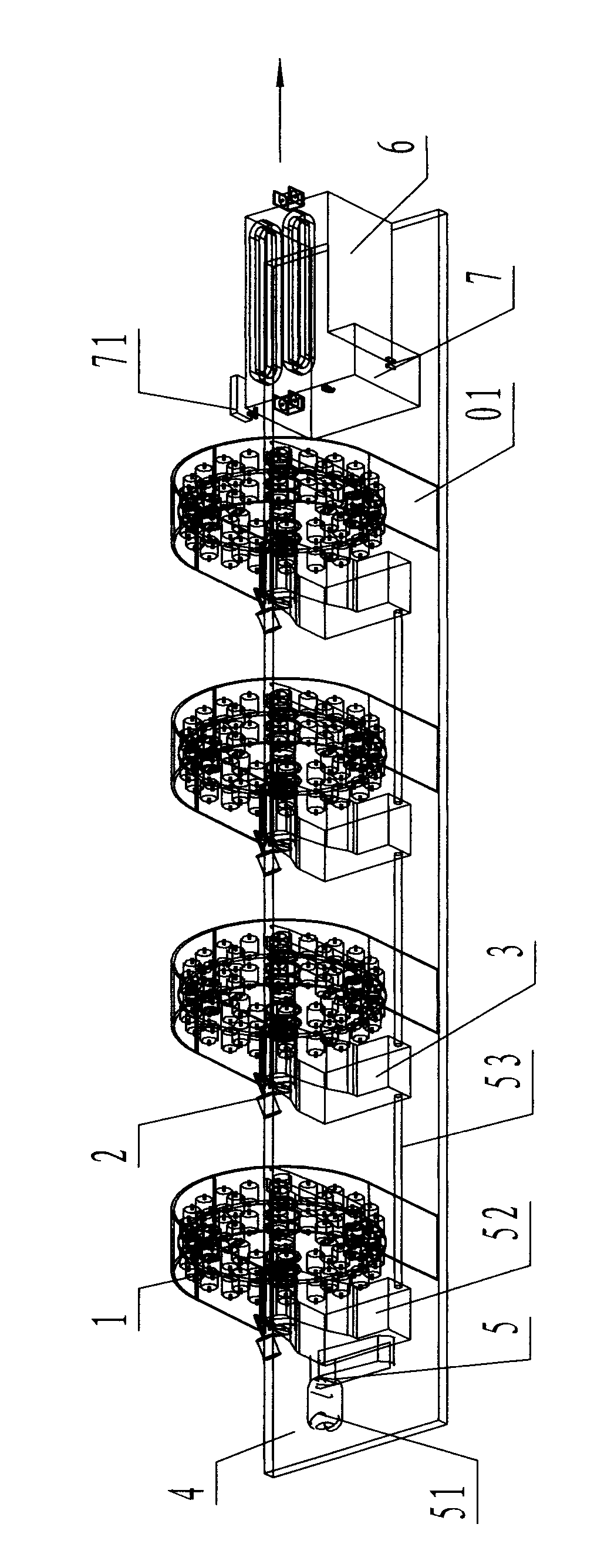

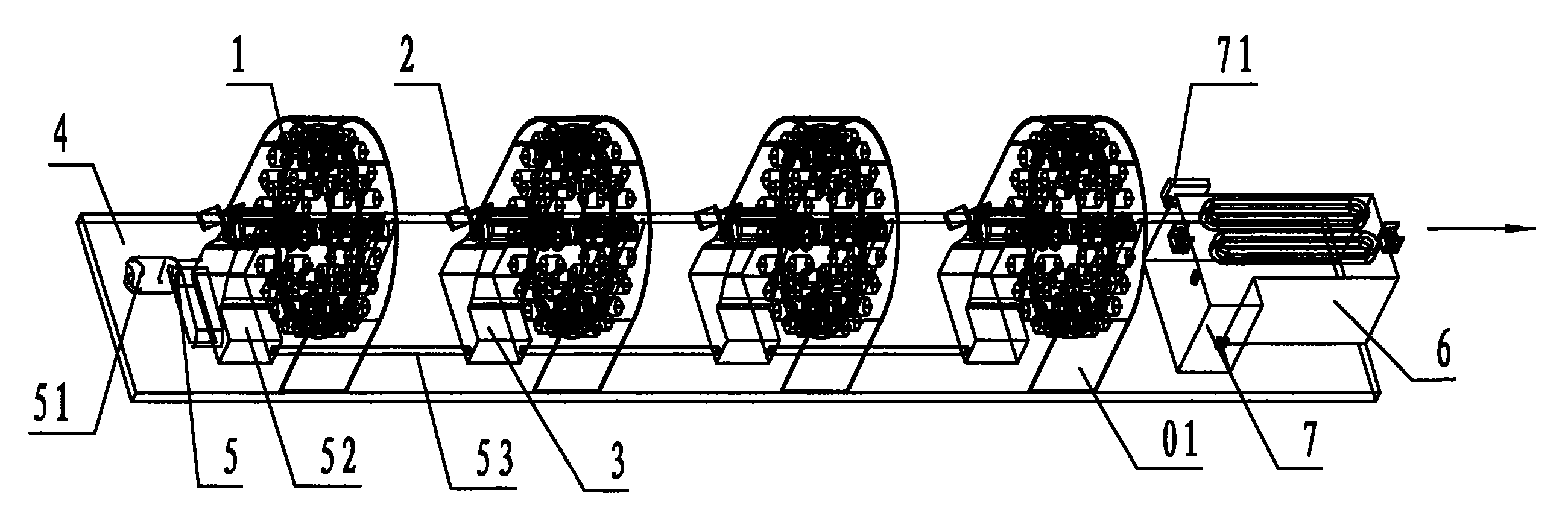

[0019] refer to figure 1 , a multi-layer composite rubber hose automatic winding molding machine of the present invention, comprising steel wire winding double-sided spindle disc 1, rubber / cord winder 2, roller bracket 3, base 4, driving device 5, traction device 6, computer control Table 7, wherein: the steel wire winding double-sided spindle disk 1 is horizontally positioned on the axis, vertically arranged on the support, driven by the transmission gear arranged in the support to rotate in a circle, the center is provided with a circular central through hole and both sides are provided with There is a circular steel disc with a split ring; both sides of the steel wire winding double-sided spindle disc 1 are evenly equipped with a number of rotating shafts for loading I-shaped wheels, and the axis of the rotating shaft is parallel to the axis of the steel wire winding double-sided spindle disc 1. The word wheel is a spindle loaded with steel wire. When the steel wire winds a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com