Mine hoist constantly-decelerating safe braking system with double working points

A mine hoist, safe braking technology, applied in hoisting devices and other directions, can solve the problems of long braking distance and non-braking state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The invention is further described below in conjunction with preferred embodiments:

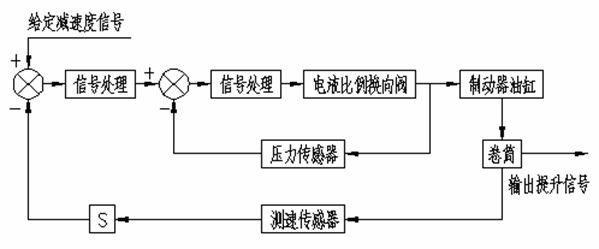

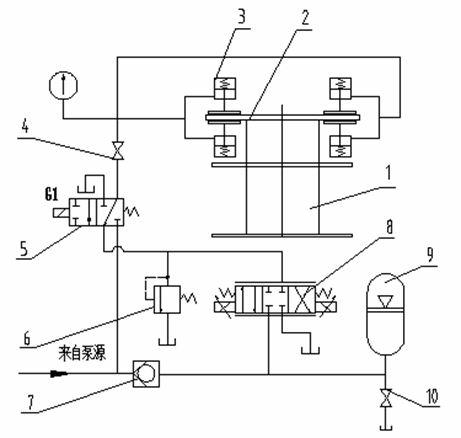

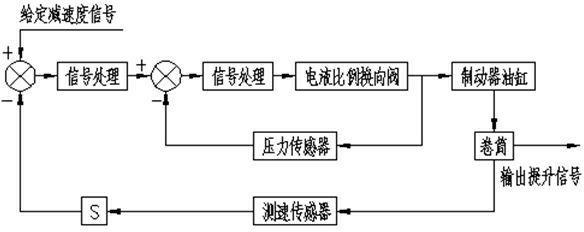

[0030] combine figure 1 , the braking system sets the working point according to the safe braking requirements of the mine hoist and the hoisting system, that is, the given deceleration value, and the constant deceleration closed-loop electrical control device compares the given deceleration value with the actual feedback signal value of the detection feedback device Finally, the control command is issued, and after the control command is amplified and corrected, it is converted into a hydraulic signal through the electro-hydraulic proportional directional valve, and the electro-hydraulic proportional directional valve outputs a hydraulic pressure (flow) signal that changes according to the input command to control the disc brake. The positive pressure output by the piston rod of the oil cylinder, the positive pressure output by the piston rod of the disc brake cylinder and the spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com