Air floating type friction-free cylinder

A frictionless cylinder, air-floating technology, applied in the direction of fluid pressure actuating devices, etc., can solve the problems of limited working stroke, limited application fields and application scope, etc., to save energy consumption, improve work efficiency, and solve complex structural problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing, the present invention will be further described:

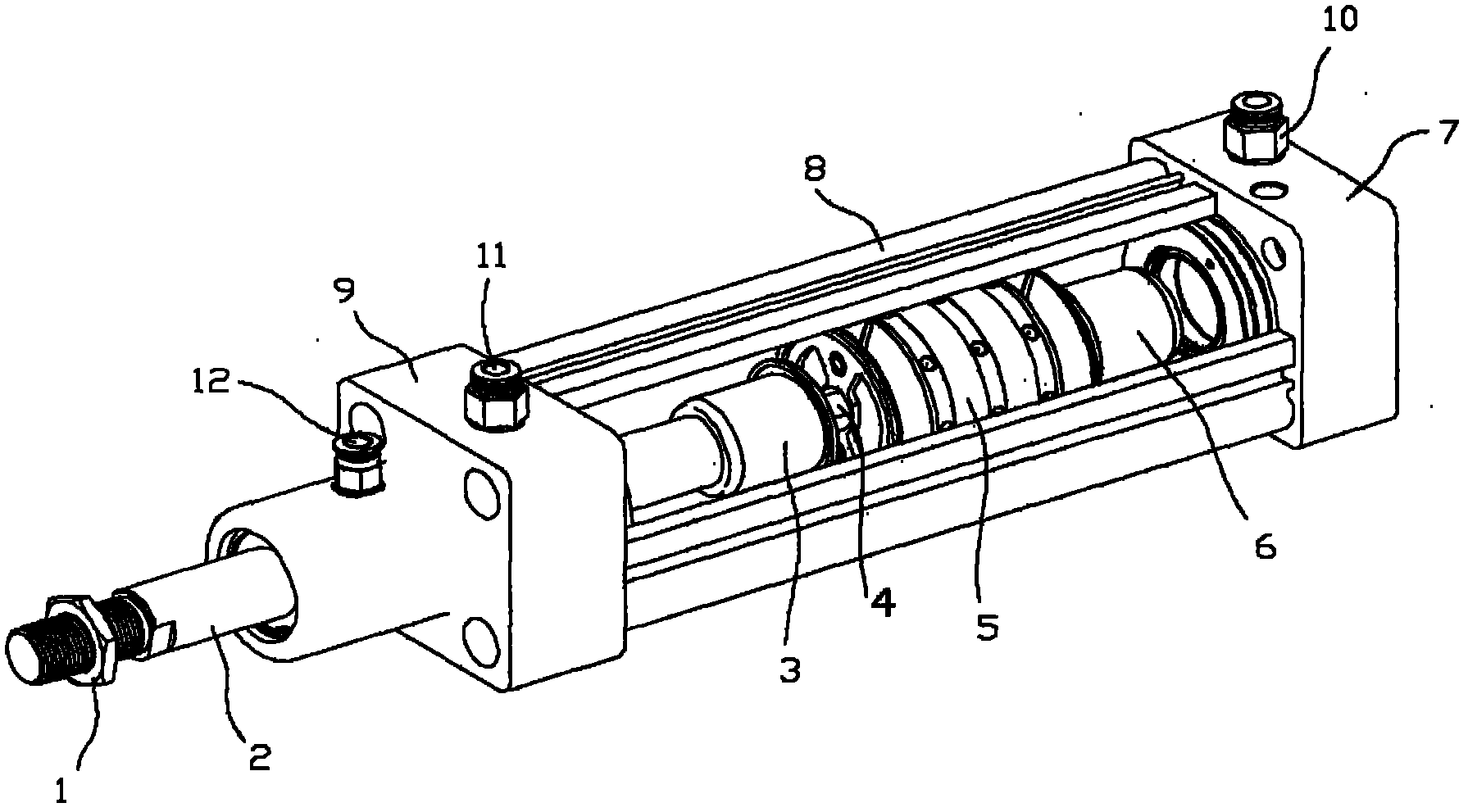

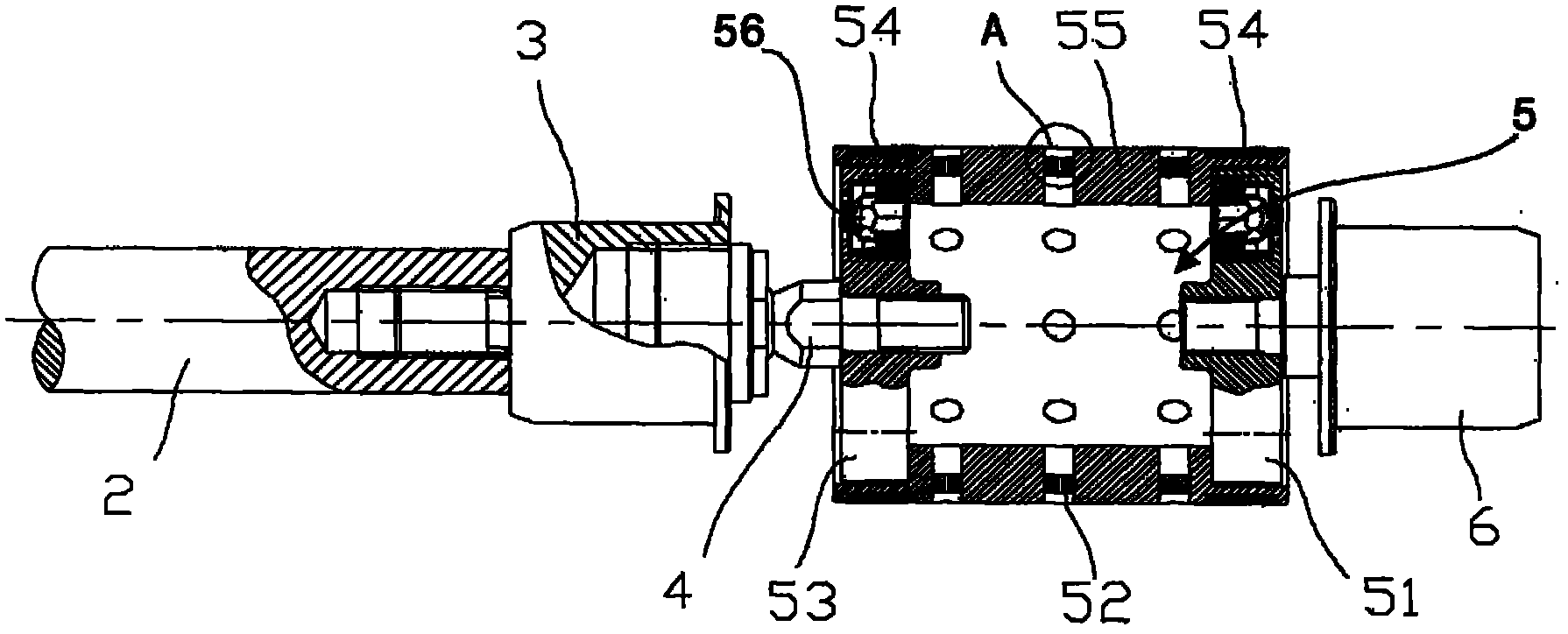

[0041] Such as Figure 1 to Figure 9 Shown, a kind of air-floating frictionless cylinder of the present invention, it comprises cylinder body and, piston 5 and piston rod 2. That is to say, the cylinder block, the piston 5 and the piston rod 2 constitute the main structure of the present invention, and are generally made of metal materials.

[0042] The cylinder block is composed of a cylinder barrel 8 and a front end cover 9 and a rear end cover 7 fixedly arranged at both ends of the cylinder barrel 8 respectively.

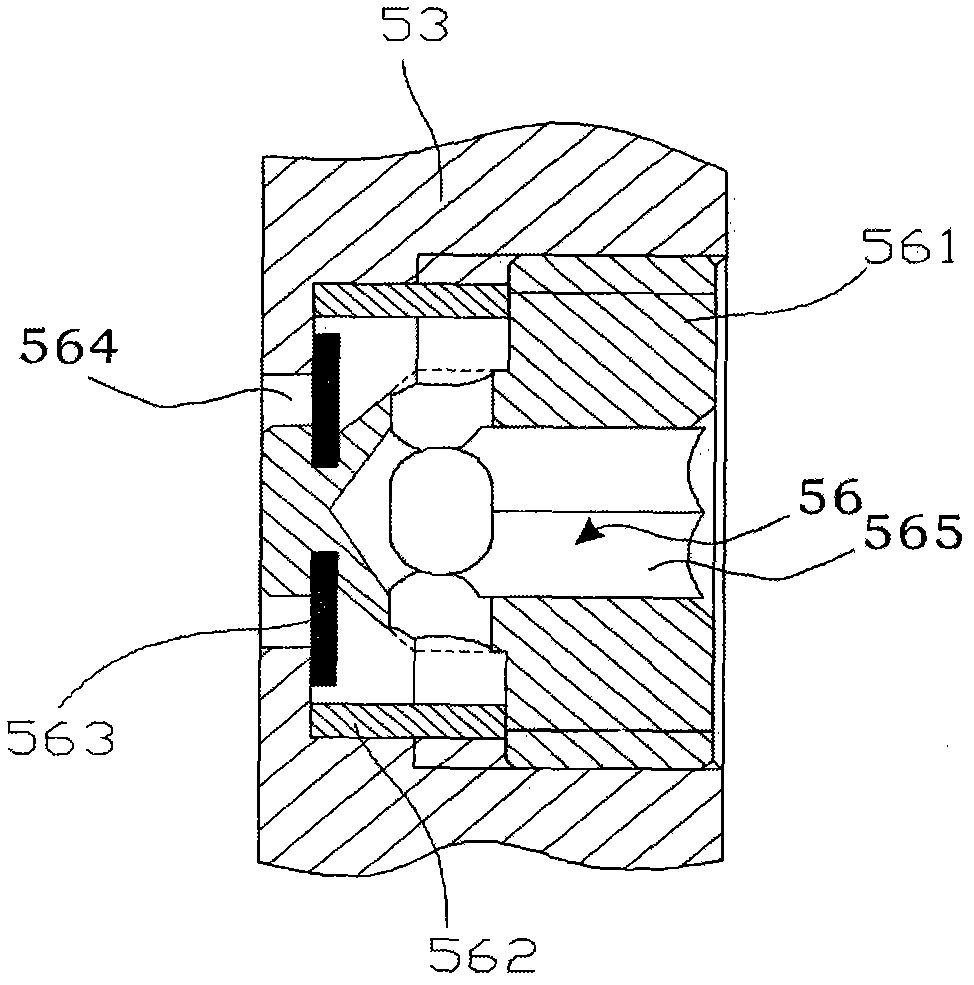

[0043] The front end cover 9 includes a front end cover housing 91 and an air bearing 94 arranged in the front end cover housing 91. A circlip 93 for a hole is provided between the front end of the air bearing 94 and the front end cover housing 91 to Air bearings 94 provide axial positioning. In addition, the rear end of the front cover housing 91 is also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com