A magnetically suspended horizontally tuned mass damper

A technology of tuning mass damping and magnetic levitation, which is applied to bridge parts, building components, bridges, etc., can solve the problems of design and control effect decline, and achieve the effects of convenient adjustment and maintenance, good lateral stability, and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

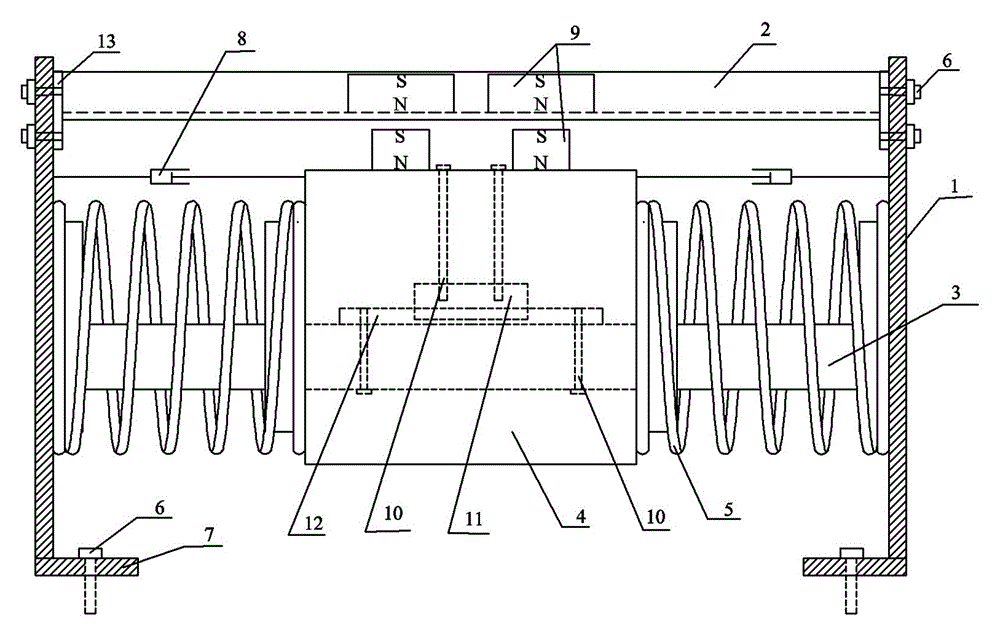

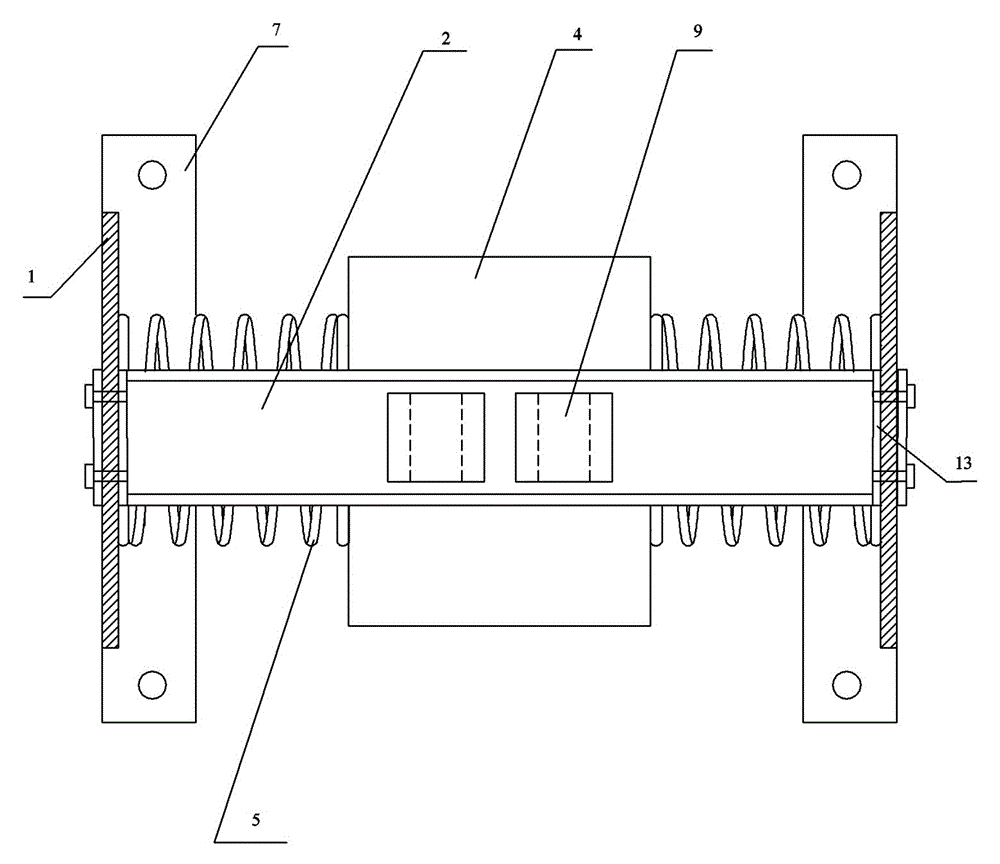

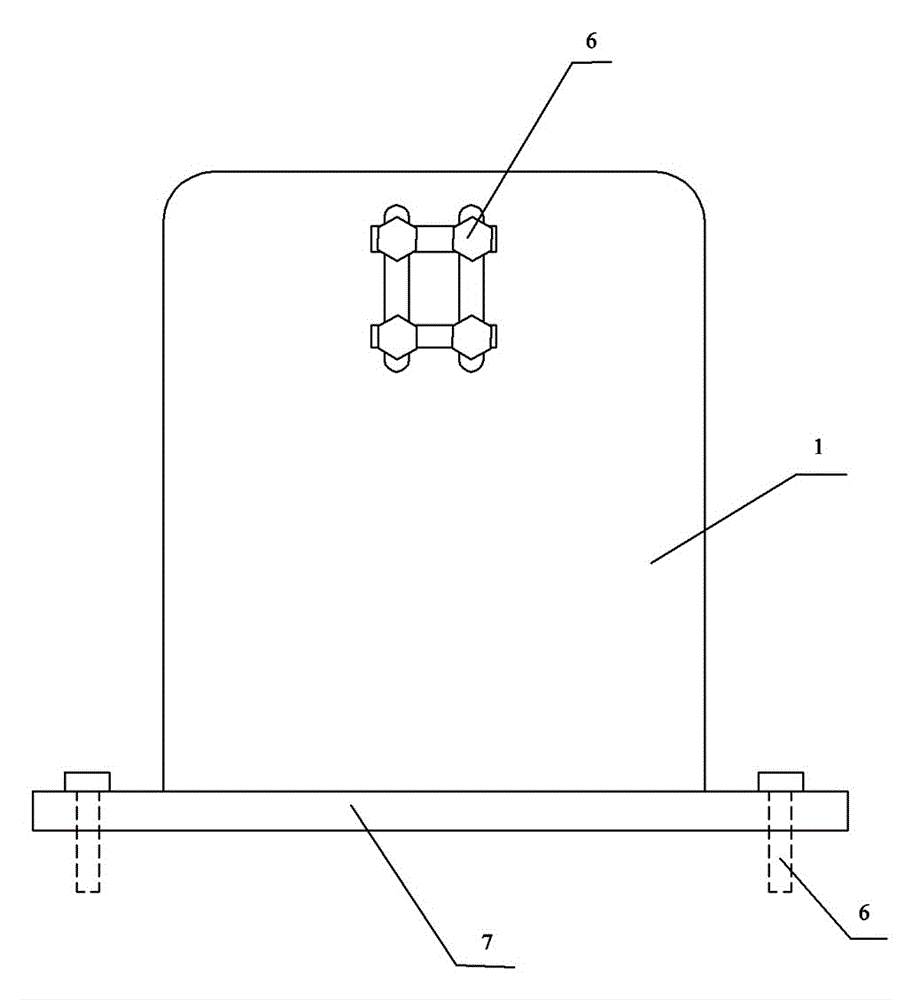

[0021] Example 1: Combining Figure 1-Figure 3 , a magnetically suspended horizontally tuned mass damper, comprising a frame body and a mass block arranged in the middle of the frame body, wherein the frame body includes vertical plates arranged on both sides, and an upper beam and a lower beam are connected between the vertical plates, and the vertical plate The lower end of the plate is provided with a support base plate, the upper beam is made of channel steel, and the upper beam and the vertical plate are fixedly connected by a backing plate and bolts and nuts. It can be adjusted up and down in the shaped hole. The rectangular permanent magnet is installed at the bottom of the channel steel; the lower beam is made of square steel, and an iron ring is arranged between the lower beam and the vertical plate. The outer diameter of the iron ring is slightly smaller than the inner diameter of the compression spring. Welding; a linear guide rail is fixed above the middle of the ...

Embodiment 2

[0023] Embodiment 2, no figure, the same part as Embodiment 1 will not be repeated, the difference is that the number of rectangular permanent magnets fixedly installed on the mass block is 2, and the number of rectangular permanent magnets corresponding to the upper beam is 1, the magnetization direction of the rectangular permanent magnet is the same, the length of the rectangular permanent magnet installed on the upper beam is equal to the length of the 2 rectangular permanent magnets on the mass block plus the distance between the 2 rectangular permanent magnets, plus damping 2 times the amplitude of the damper; the damper is a magnetorheological damper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com