An energy feedback magnetorheological-air flotation composite actuator

A technology of energy feedback and magneto-rheological damper, which is applied in the direction of fluid pressure actuators, fluid pressure actuator system components, mechanical equipment, etc., to achieve the effects of improving work efficiency, rapid positioning and stability, and strong robust anti-interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

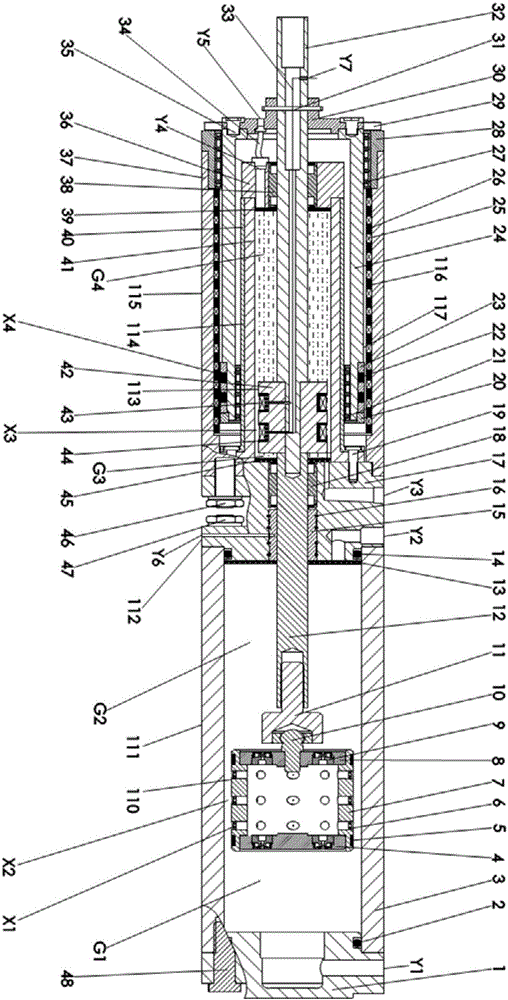

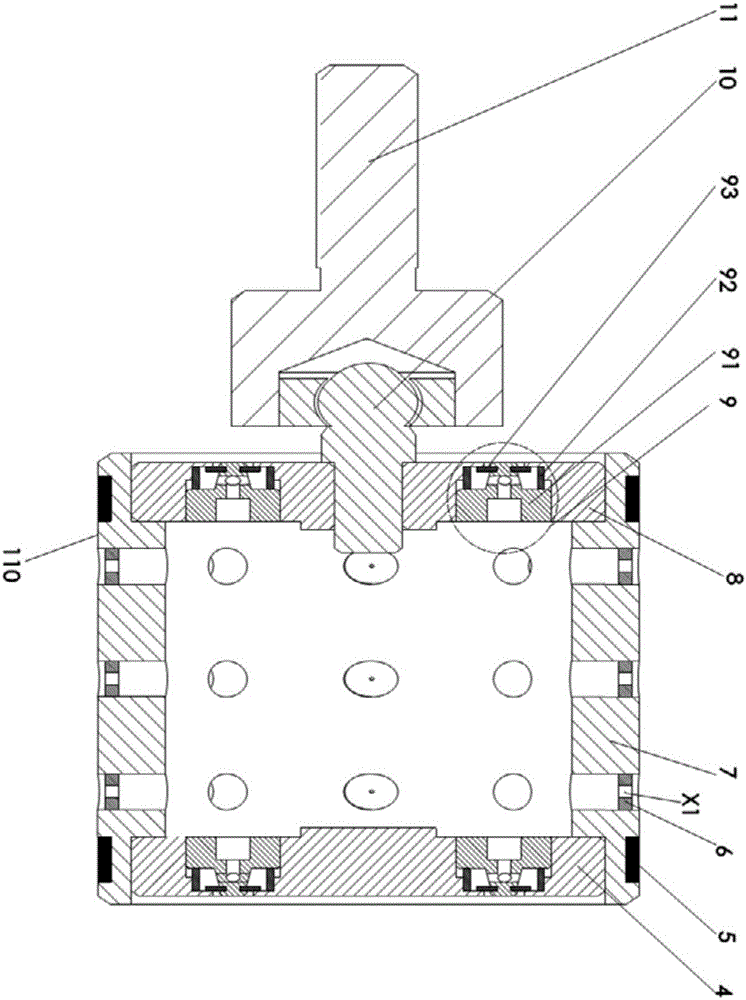

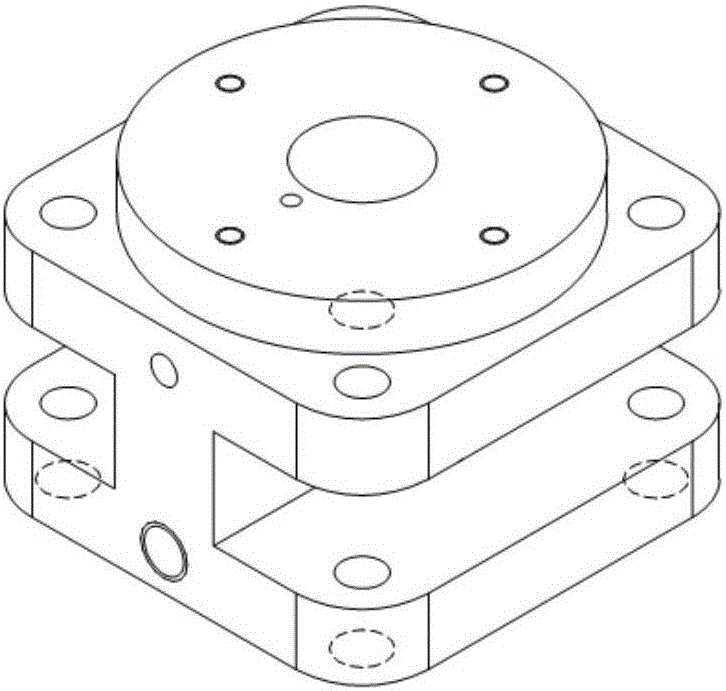

[0037] Such as figure 1 As shown, an energy feedback magneto-rheological-air bearing composite actuator according to the present invention includes a magneto-rheological damper 114, an energy feedback assembly 115, a sliding rail assembly 21, an intermediate connection assembly 112 and a frictionless cylinder 111;

[0038] The magnetorheological damper 114, the sliding rail assembly 21 and the energy feedback assembly 115 are coaxially installed from the inside to the outside; the frictionless cylinder 111 is coaxially installed with the magnetorheological damper 114 at the front and rear sides; the The frictionless cylinder 111 , the magneto-rheological damper 114 and the energy feedback assembly 115 are coupled as a whole through an intermediate connection assembly 112 .

[0039] Such as figure 1 As shown, the frictionless cylinder 111 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com