Wet-type clutch

A wet double clutch and clutch technology, applied in the direction of clutches, friction clutches, fluid-driven clutches, etc., can solve the problems of large diameter of the rotating sealing surface of the clutch, inconvenient maintenance of the clutch, and difficulty in rotating sealing, so as to reduce processing costs, facilitate maintenance, Clutch compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

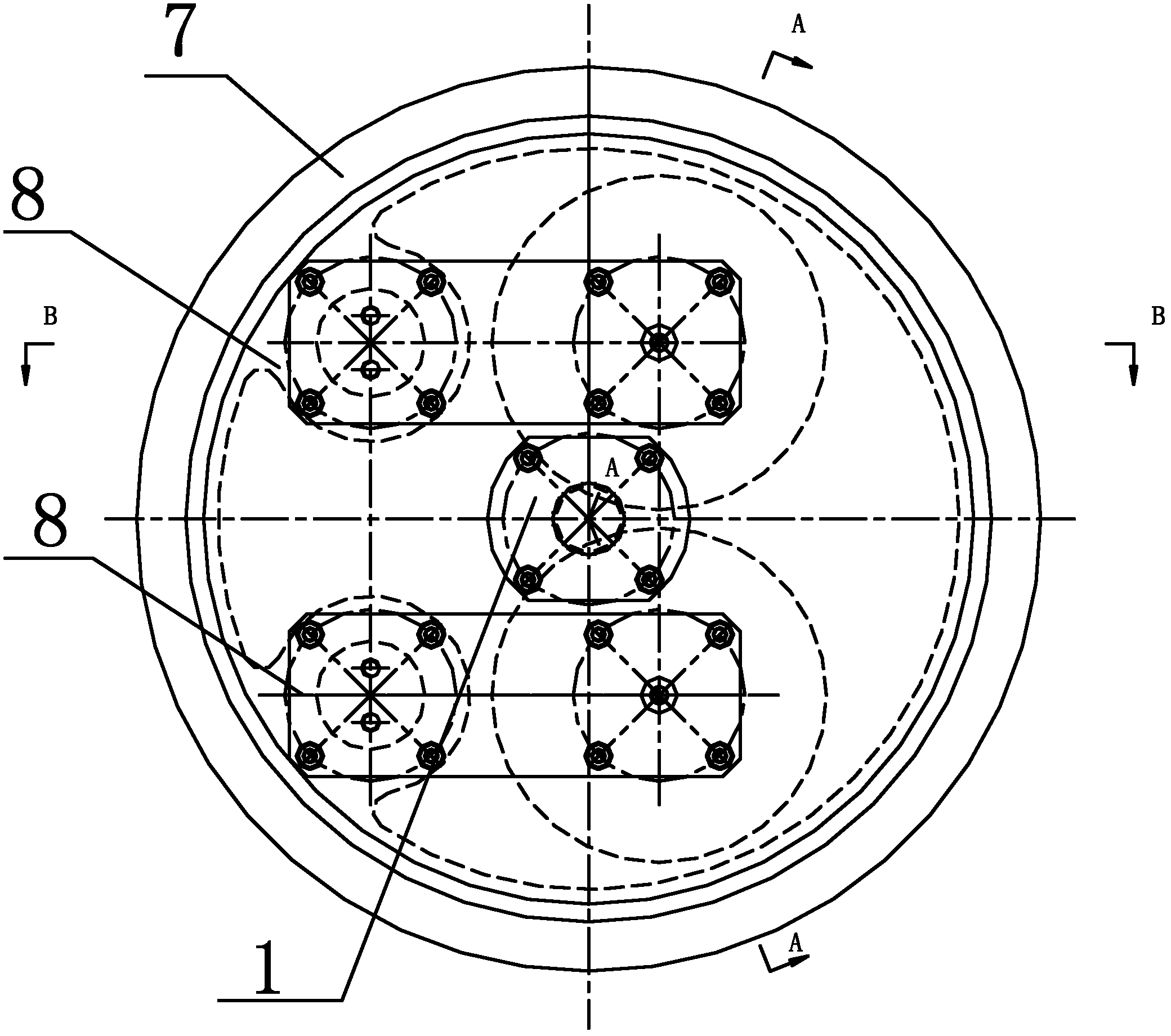

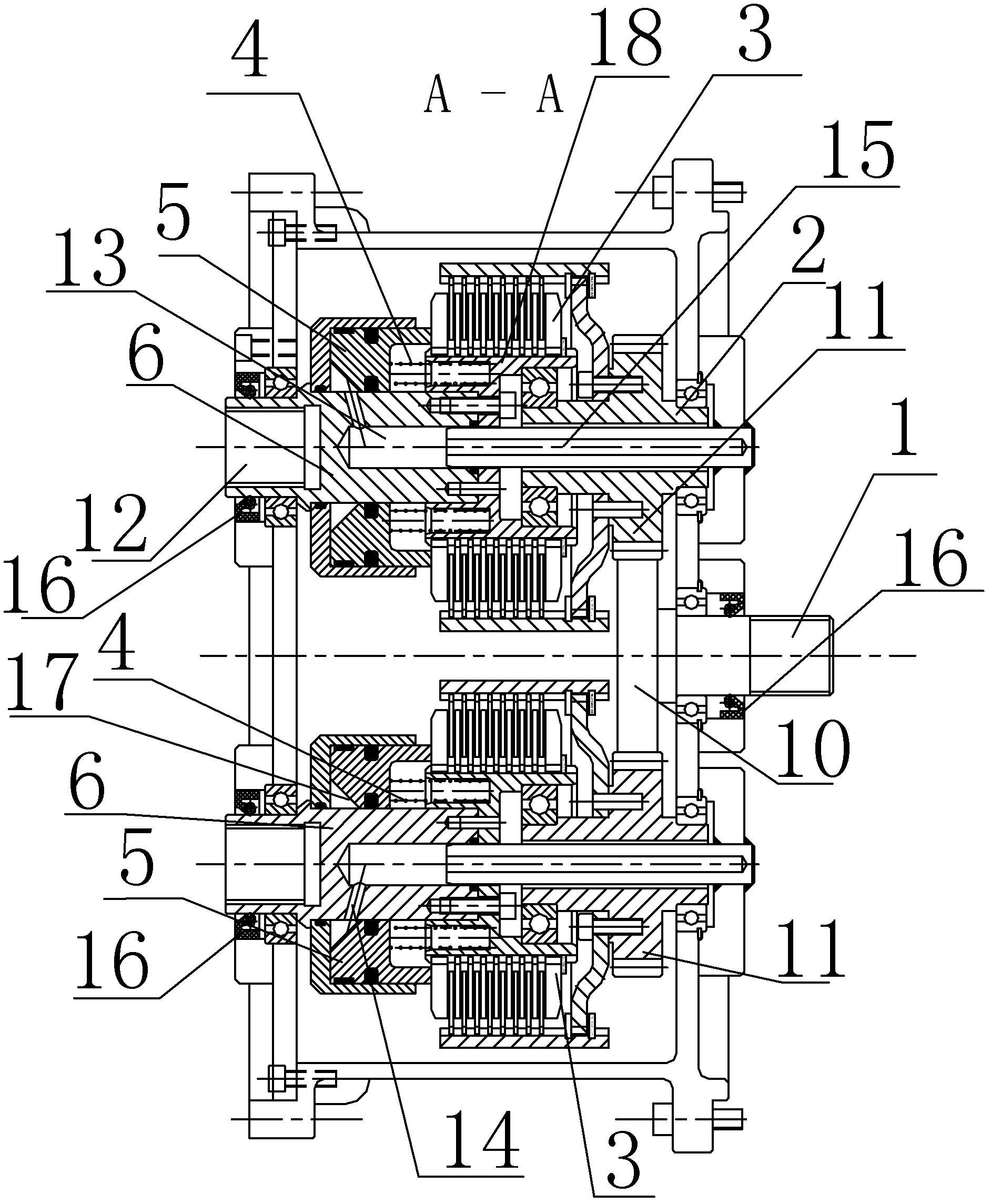

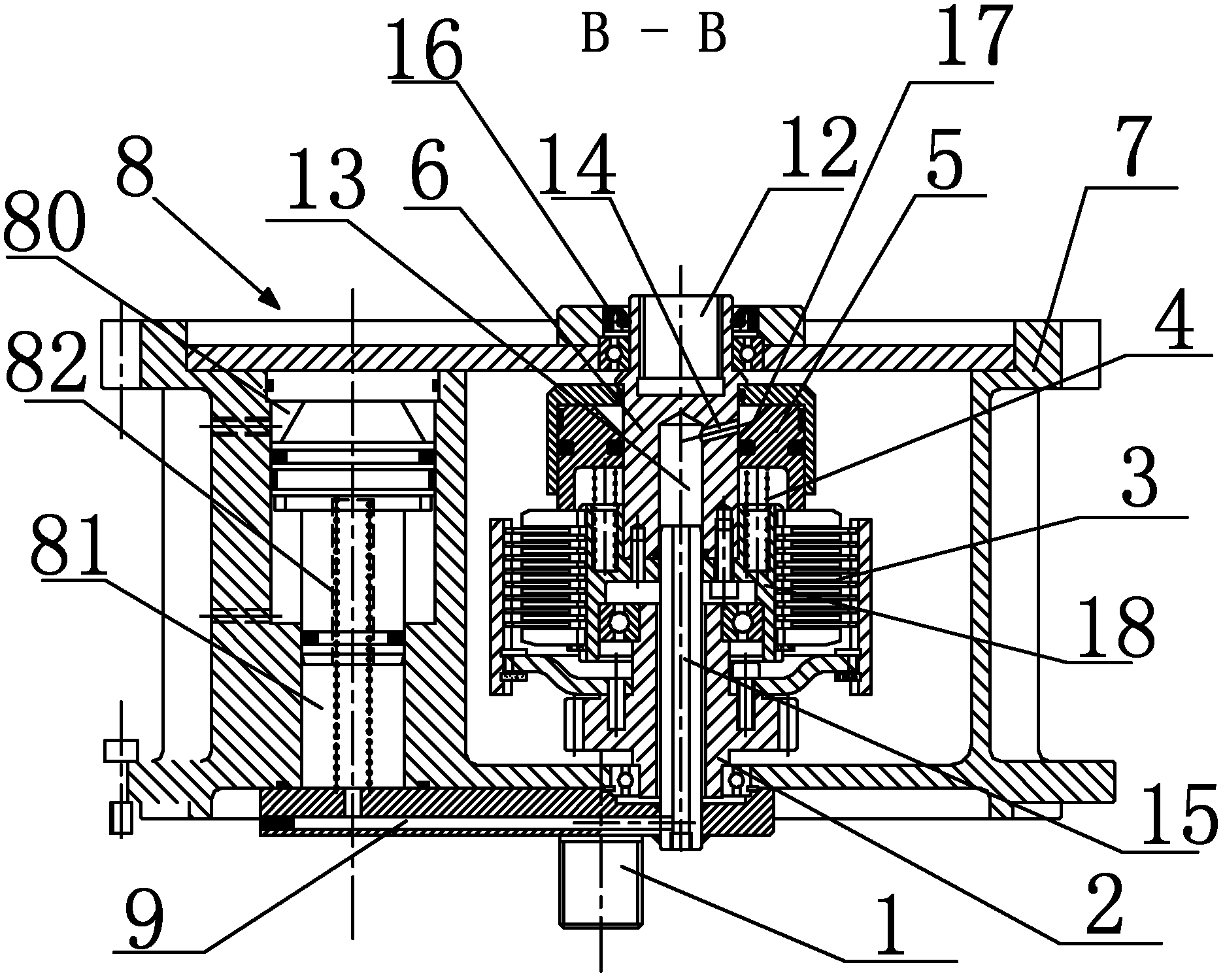

[0022] Such as Figure 1~3 A wet dual clutch shown, a wet dual clutch, includes a clutch case 7, an input shaft 1 connected to the clutch case 7 through a bearing, an input shaft gear 10 fixed on the input shaft 1, and it also includes two An output shaft assembly arranged in parallel and two gas-liquid conversion booster cylinders 8, each output shaft assembly includes a clutch driving shaft 2, a clutch driven shaft 6 coaxially arranged with the clutch driving shaft 2, fixed on the clutch The clutch 3 between the driving shaft 2 and the clutch driven shaft 6, the hydraulic cylinder 5 that drives the clutch 3, and the compression spring group 4 that separates the driving clutch 3, wherein each clutch driving shaft 2 and clutch driven shaft 6 pass through The bearing is connected with the clutch case 7, and the driving shaft gear 11 meshing with the inpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com