Gas pressure layering control method of pulse-combustion industrial furnace

A technology of gas pressure and industrial furnaces, which is applied in the direction of controlling combustion, lighting and heating equipment, etc., and can solve the problems of linearity reduction of control valves, poor control accuracy of furnace gas pressure, furnace temperature control accuracy, material heating quality and energy consumption and other problems to achieve the effect of improving linearity and ensuring control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

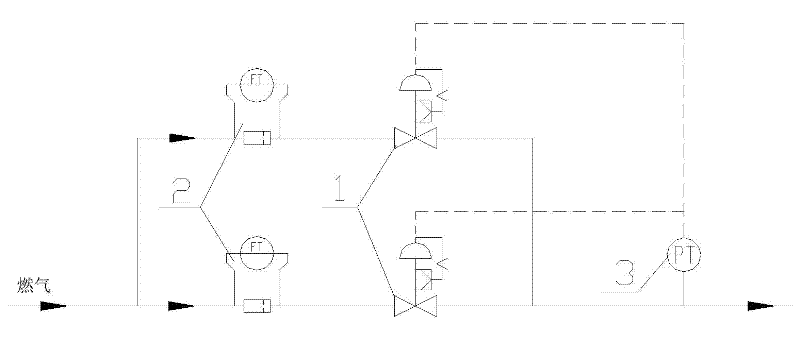

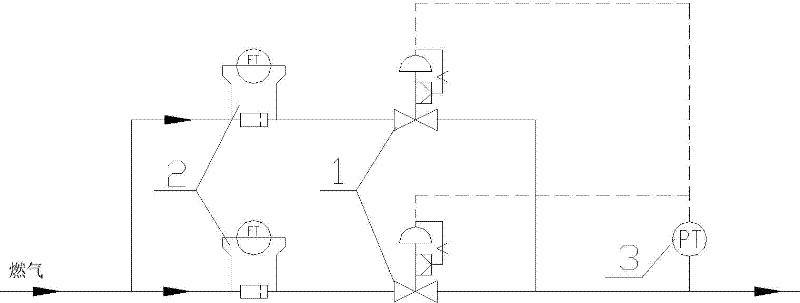

[0012] The pulse combustion industrial furnace gas pressure layered control method of the present invention includes a gas control circuit composed of a flow detector and a control valve in series, and a pressure transmitter is arranged on the gas main pipe at the end of the gas control circuit to collect gas pressure information Feedback to the controller to adjust the gas pressure through the control valve, the method includes the following steps:

[0013] Step 1. According to the working load of the industrial furnace, the gas pressure is divided into two levels, corresponding to the normal load and small load working status of the industrial furnace;

[0014] Step 2, using the two gas control loops to control the gas pressure of the industrial furnace, the pressure transmitter collects the gas pressure information and feeds it back to the control valve in each gas control loop to adjust the opening of the control valve;

[0015] Step 3. According to the gas pressure strati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com