Novel combustion-supporting ignition system

An ignition system and a new type of technology, applied in the direction of combustion ignition, combustion method, lighting and heating equipment, etc., can solve the problems of waste of heavy oil resources, insufficient combustion of heavy oil, large amount of heavy oil, etc., to overcome high operating costs and operational response Fast speed and excellent oil consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

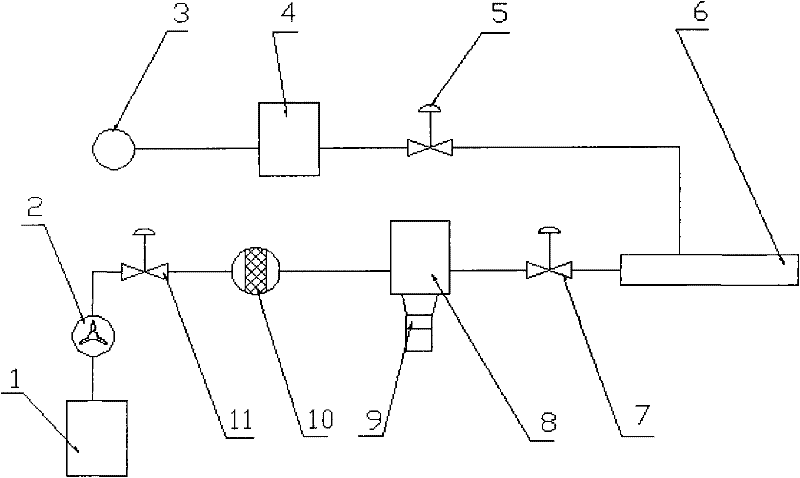

[0010] After connecting the air compressor (3), the air storage tank (4) and the air flow cut-off valve (5) sequentially with pipelines, they are connected to the air inlet of the fuel gun (6), and the fuel storage tank (1), oil pump ( 2), oil filter (10), atomization chamber (8), and oil flow stop valve (7) are connected in sequence with pipelines, connected to the oil inlet of fuel gun (6), and ultrasonic transducer (9) ) and the launch end of the spray chamber (8) are fixed together;

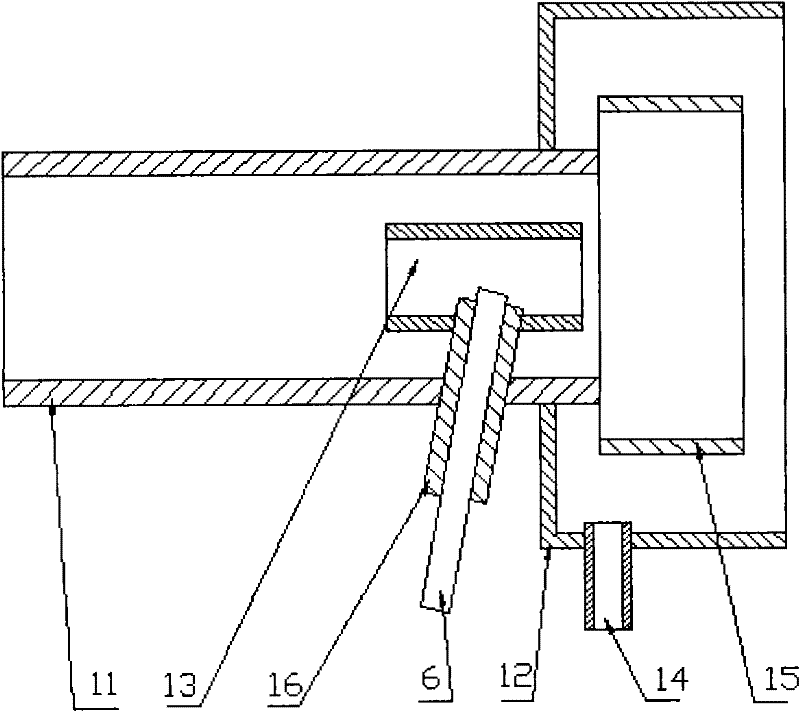

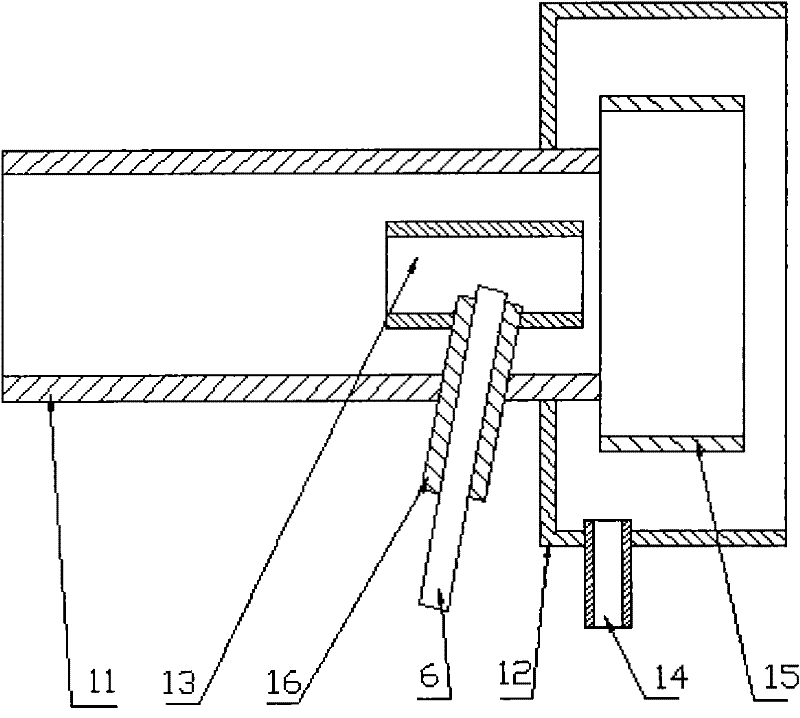

[0011] Install and fix the primary combustion chamber (13) in the middle of the right mouth of the material pipe (11), the protective pipe (16) communicates with the interior of the primary combustion chamber (13) from the outside of the material pipe (11), and the fuel gun (6 ) is inserted into the primary combustion chamber (13) from the protective tube (16), and the secondary combustion chamber (15) is installed and fixed on the right port of the material pipe (11). The secondary combustio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com