Heat collecting temperature controllable manufacturing method and product of vacuum solar heat collecting device

A heat collection device, solar heat collection technology, applied in the direction of solar heat device, heating device, solar heat energy, etc., can solve the problems of inconvenient covering, aging absorption film, not equipped with heat dissipation facilities, etc., and achieve the effect of reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

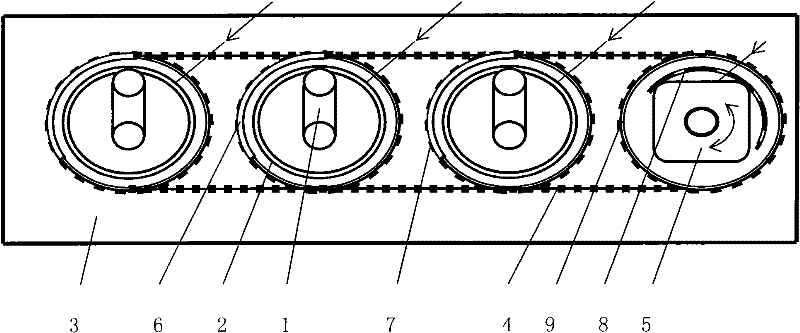

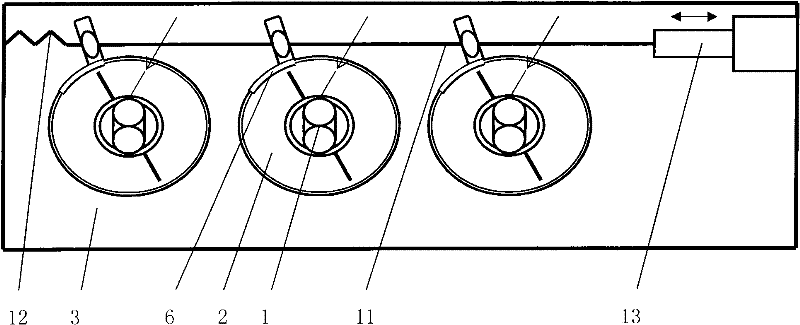

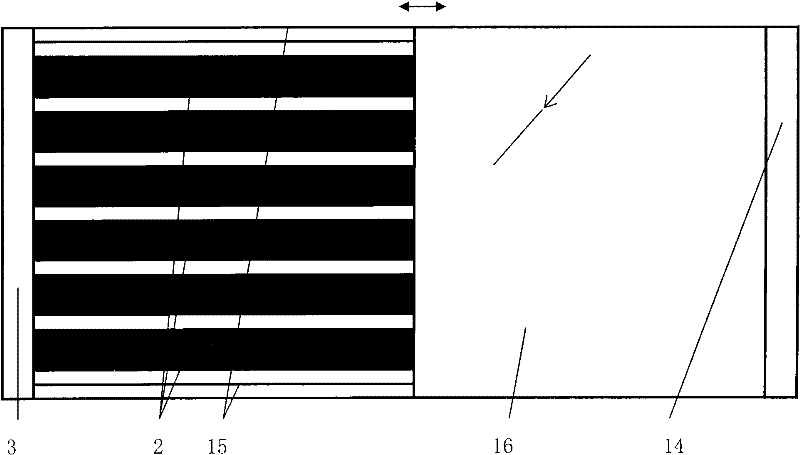

[0020] figure 1 Among them, the vacuum heat collecting element 2 of the internal fin plate metal runner heat exchanger 1, the collection box 3 of the built-in heat exchanger 1 collection pipe, the tail box and the junction box 3 tail box are connected by means of movable cooperation. The connecting parts form a fully automatic metal runner vacuum solar heat collection device with controllable heat collection temperature. Each heat collecting element 2 is connected with a synchronous transmission belt 4 in transmission. The synchronous transmission belt 4 is connected with the motor-driven power head 5 in transmission. The motor-driven power head 5 can be used for forward and reverse rotation. Part of the outer surface of each heat collecting element 2 cover glass tube is coated with black silica gel to form a light-shielding layer 6 . The heat collecting element 2 is connected with the foundation by means of a rotary connection pair. On the cover glass tube that heat colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com