Liquid level measurement method based on magnetic coupling and optical fiber pair array

A liquid level measurement and optical fiber pair technology, applied in the field of sensors, can solve the problems of blocking the movement of the baffle, the light cannot pass through, and the fouling of the baffle, so as to achieve the effect of wide application, elimination of interference, and accurate and reliable measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but is not limited to the content described below.

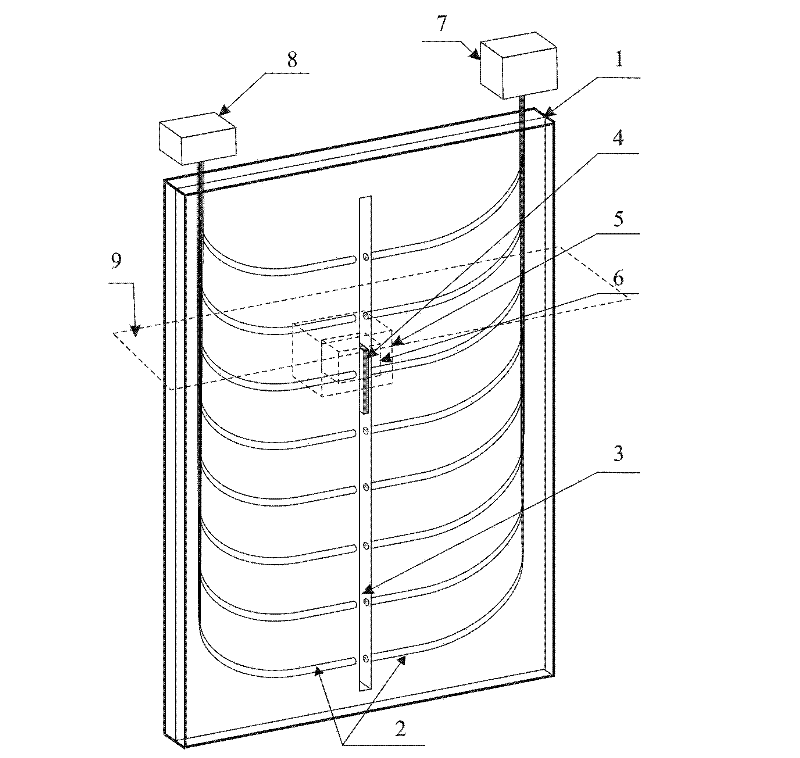

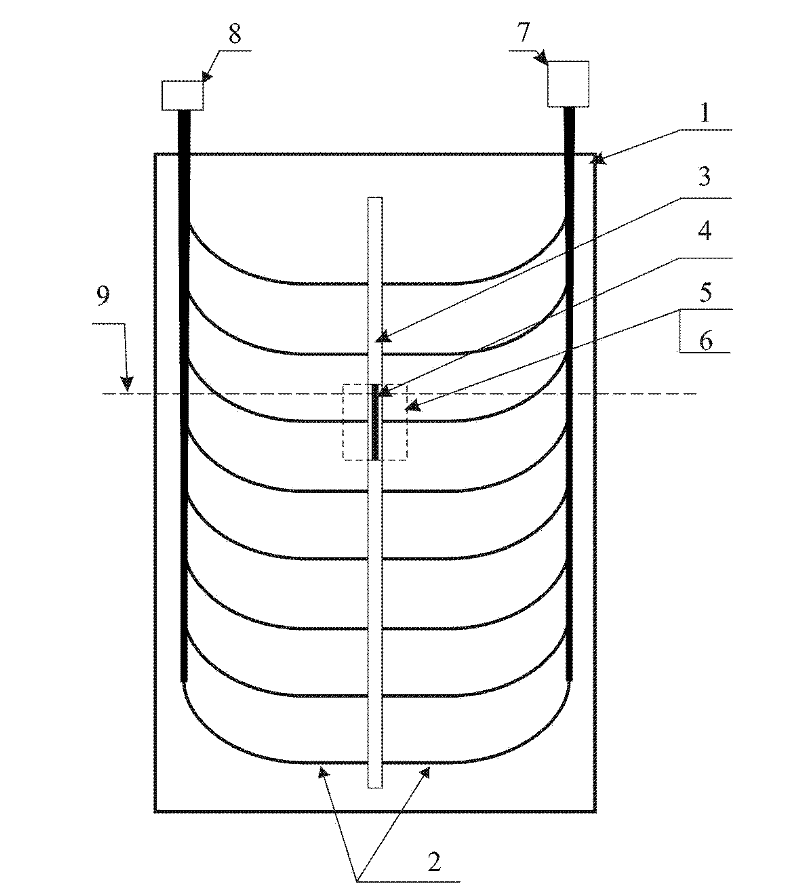

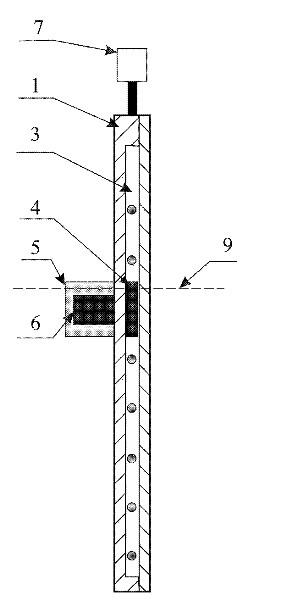

[0023] The liquid level measurement method based on magnetic coupling and optical fiber pair array provided by the present invention is realized by preparing a corresponding liquid level measurement sensor. The structure of the liquid level measurement sensor is as follows figure 1 As shown: it is mainly composed of a column 1, an optical fiber pair 2, a narrow slot guide groove 3, a magnetic light barrier 4, a float 5, a permanent magnet 6, a light source 7 and a light detector 8.

[0024] The column 1 is used to support the pair of optical fibers 2, and seal the pair of optical fibers 2 and the magnetic light barrier 4 inside the column to isolate it from the liquid to be measured. The column is made of polytetrafluoroethylene material. The shape and height of the column are designed according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com