Single-frequency polarized laser interferometer and optical-path-multiplying high-sensitivity laser strain meter

A technology of laser interferometer and strain gauge, applied in the direction of instruments, optical devices, measuring devices, etc., can solve the problems of great influence on sensitivity and measurement accuracy, non-linear output, and not very suitable for reliability and stability of extensometers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

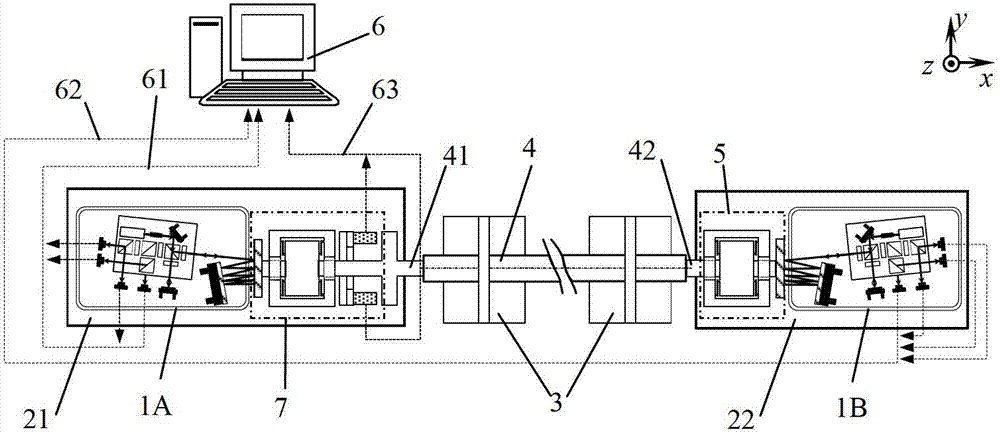

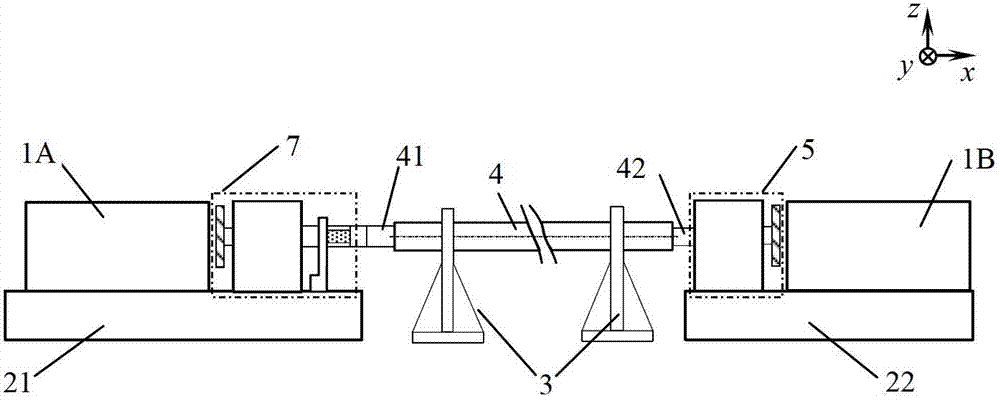

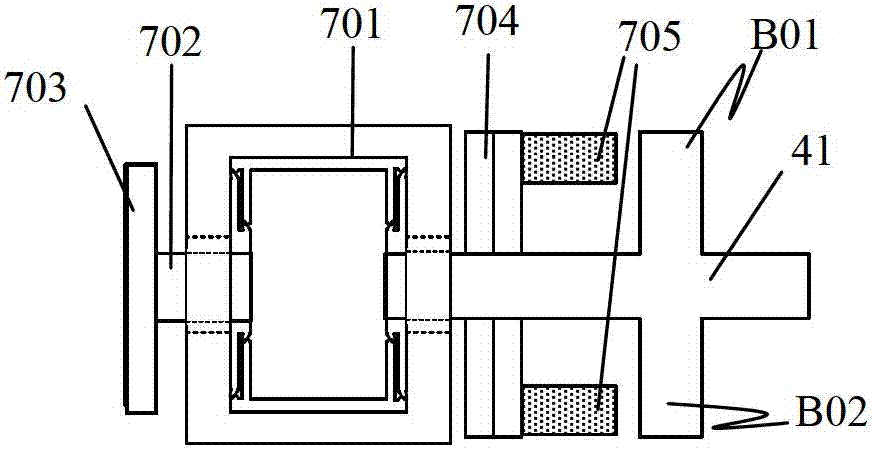

[0055] combine Figure 1a and Figure 1b , optical path multiplication high laser strain gauge, consists of two single-frequency polarization laser interferometers 1A, 1B, measuring bedrock 21, 22, suspension system 3, measuring baseline rod 4, mirror limit device 5, signal recording and processing The system 6 is composed of a calibration and limit device 7. The single-frequency laser interferometer 1A fixed on the first bedrock 21 and the first measuring mirror 703 form a complete single-frequency polarization laser interferometer; the first measuring mirror 703 Connect with one end 41 of the measuring baseline 4 through the calibration and the limiting device 7; the other end 42 of the measuring baseline 4 is equipped with a mirror limiting device 5, and the reflecting mirror limiting device 5 is installed with the second measuring mirror 503, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com