Analytic method and device for gas with coketar particles

An analysis device and gas technology, applied in the field of gas analysis, can solve the problems of damage to precision analysis instruments, heavy maintenance workload, and increased measurement errors of gas analysis instruments, so as to improve use efficiency, reduce engineering maintenance, and improve measurement The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

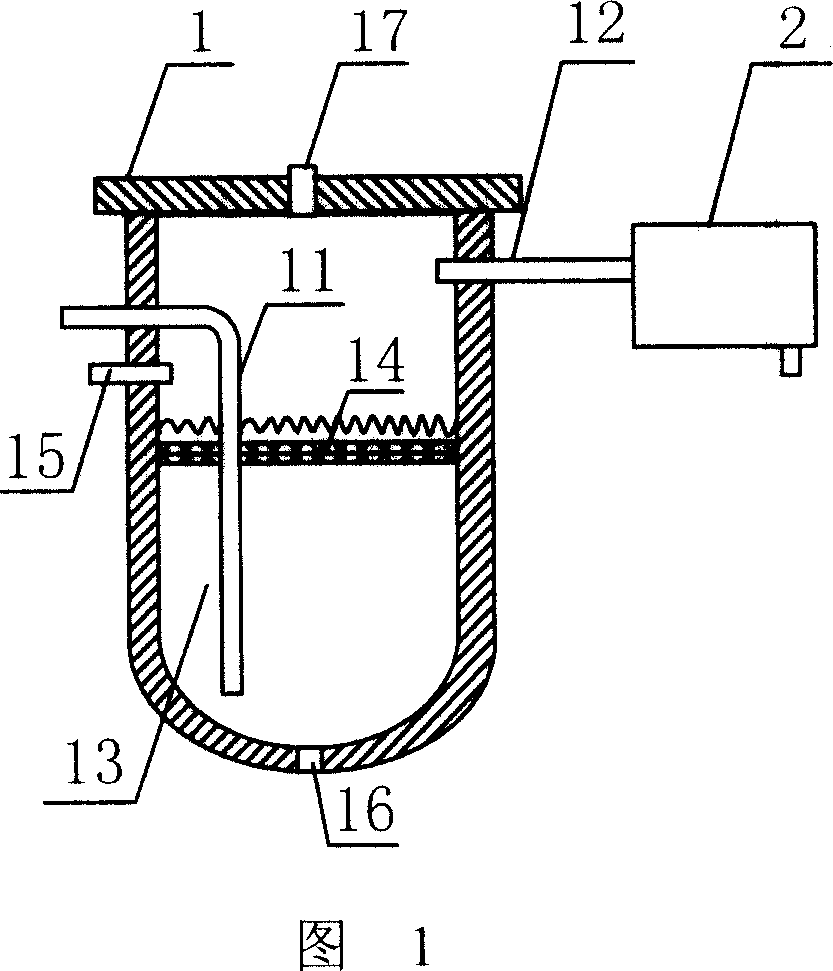

[0022] As shown in FIG. 1 , a device for implementing the method for analyzing gas with tar particles of the present invention is applied in the field of coking. The analysis device includes a tar particle removal device and an analysis instrument 2 . The tar particle removal device includes a sealed container 1 . The analysis instrument 2 is a semiconductor laser absorption spectrum analyzer.

[0023] Air intake pipe 11 and air outlet pipe 12 are installed on the described airtight container 1, and liquid 13 and filtering device 14 are housed inside, and liquid 13 in the present embodiment uses carbon tetrachloride, and filtering device adopts flat filter screen, is installed in described liquid 13 the lower part of the liquid level. One end of the air inlet pipe 11 extends into the liquid 13 under the filter device 14 . The upper side wall of the airtight container is provided with a liquid inlet 15 , the bottom is provided with a liquid outlet 16 , and the end cover is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com