Device and method for online detection on appearance defect of minitype connecting part based on machine vision

A technology of appearance defects and machine vision, which is applied in the direction of measuring devices, optical devices, and optical testing of defects/defects, can solve problems such as difficulty in adapting to detection speed, poor objectivity of quality standards, and slow detection methods, so as to improve detection accuracy. and anti-interference ability, improve efficiency and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

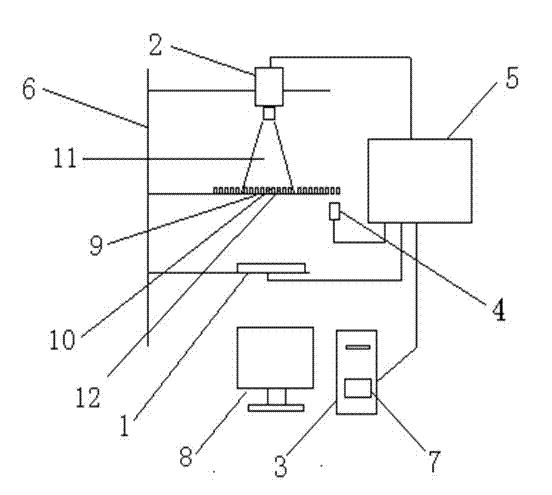

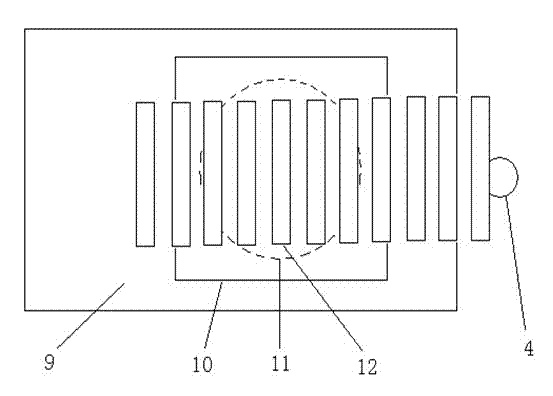

[0031] Such as figure 1 As shown, the machine vision-based online detection device for small connector appearance defects of the present invention mainly includes a red LED backlight 1, an industrial camera 2, a PC 3 containing an image acquisition card 7, a proximity switch 4, a PLC controller 5 and a bracket 6 . Among them, the red LED backlight 1 is fixedly installed on the bracket 6, and the industrial camera 2 is installed on the bracket 6 and can move up and down, so as to adjust the distance between the industrial camera 2 and the detected small fine blanking connector 12 so that it can be The detected small fine blanking connector 12 is in a suitable position in the field of view of the industrial camera 2, and the suitable position means that the detected small fine blanking connector 12 occupies about 3 / 4~4 / 5 of the field of view of the industrial camera 2 . The red LED backlight 1 is located directly below the lens of the industrial camera 2 . The bracket 6 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com