Photolithographic illumination device using mercury lamp light source

A technology for lighting devices and mercury lamps, which is applied in the field of semiconductors and can solve problems such as the inability to change the lighting mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In the following, preferred embodiments according to the present invention will be described in detail with reference to the accompanying drawings.

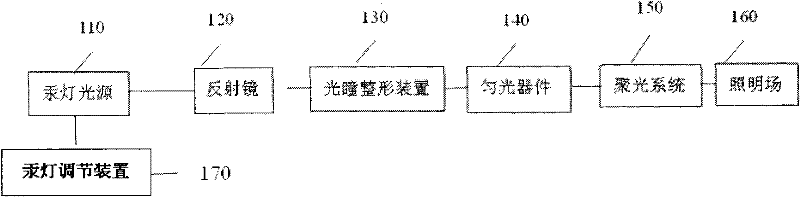

[0027] Such as image 3 As shown, the present invention discloses a lithography lighting device using a mercury lamp light source, comprising: a mercury lamp light source 110; a mercury lamp position adjusting device 170, which changes the light emitted by the mercury lamp light source 110 by moving the position of the mercury lamp Coherence factor; a reflective bowl 120, used to gather light energy of the mercury lamp; a pupil shaping device 130, to realize the conversion of illumination mode and the change of illumination coherence factor; a uniform light device 140, to obtain better illumination uniformity ; a focusing system 150 ; and an illumination field 160 . The reflective bowl 120 collects the light energy of the mercury lamp 110 and makes it enter the pupil shaping device 130 . The pupil shaping device 130 is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com