Integrated LED (light emitting diode) module with thin fly's-eye lens

A technology of LED modules and fly-eye lenses, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as ineffective waterproofing, affecting light distribution stability and service life, hindering heat dissipation, etc., to reduce internal refraction loss, Conducive to heat dissipation and waterproof, reduce the transient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

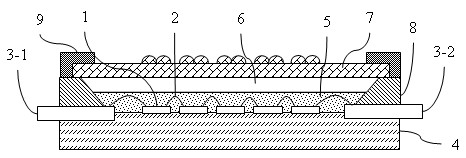

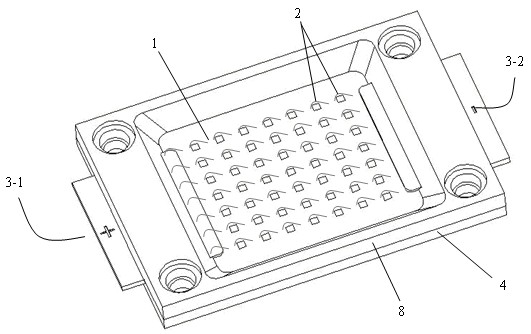

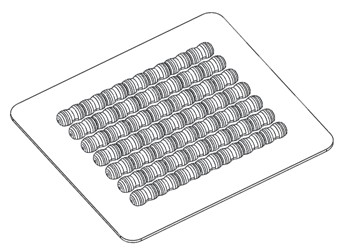

[0014] Such as figure 1 As shown, the integrated LED module with thin fly-eye lens includes LED chip 1, gold wire 2, positive electrode 3-1, negative electrode 3-2, substrate 4, fluorescent glue 5, transparent silica gel 6, thin fly-eye lens 7, reflective cup Pressing plate 8, fixed pressing ring 9; reflective cup pressing plate 8 is arranged on the substrate 4, and surrounds a cavity, a plurality of LED chips 1 are arranged in an array and fixed on the substrate 4, and are in the cavity surrounded by the reflecting cup pressing plate 8 Among them, the gold wire 2 connects the LED chip 1 and connects it to the positive electrode 3-1 and the negative electrode 3-2, the LED chip 1 is covered with fluorescent glue 5, and the thin fly-eye lens 7 is installed on the reflective cup pressure plate through the fixed pressure ring 9 8 or on the substrate 4, the transparent silica gel 6 is filled with the space surrounded by the thin fly-eye lens 7, the reflective cup pressing plate 8 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com