Manufacture of smoking products using hot extrusion

A smoking product and extruder technology, which is applied in the field of smoking product manufacturing using hot extrusion, can solve problems such as interruption of feeding material flow, and achieve the effects of reducing torsion resistance, eliminating consumption and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

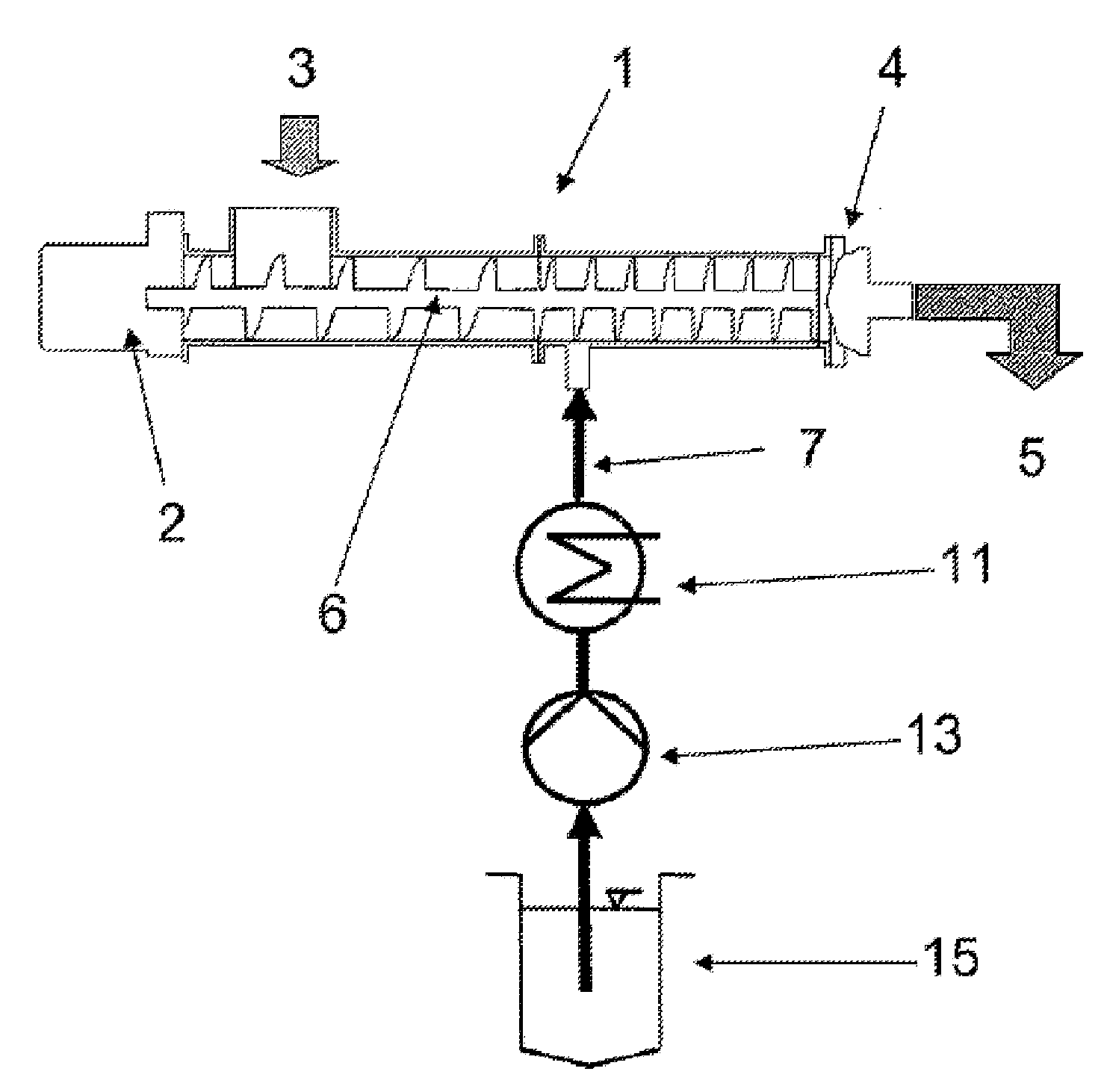

[0032] The device for carrying out the present invention is in figure 1 shown in . The extruder 1 shown has a drive mechanism 2 for a conveying screw 6 housed in the housing, with which the tobacco material is conveyed and compressed, which enters the extruder 1 at the position indicated by 3 middle. The screw 6 conveys and compresses the tobacco material until the tobacco material reaches the forming tool 4 on the right, where the tobacco material is discharged, for example via a self-opening and closing shear gap (Scherspalt), and is then extruded as a fibrous extrudate (Extrudat) 5 Provided for use in the manufacture of smoking articles. According to the invention, roughly in the center of the device, a heated process fluid 7 is introduced into the extruder 1 , wherein the fluid 7 (for example heated water) has previously been heated in the heater 11.

[0033] In the embodiment shown here, therefore, the humidity-conditioning medium or fluid 7 (for example water, steam)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com